- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

5

-

Weight (KG):

-

1100

-

Applicable Industries:

-

Laser cutting parts, Flame cutting parts, Precision sheet parts, metal sheet parts, stamping parts, automatic steel plate

-

Product name:

-

Automatic Metal Deburring Machine

-

Usage:

-

All flat metal

-

After-sales Service Provided:

-

1 Year

-

Maximum machining height:

-

80mm

-

Brush roller diameter:

-

300mm

-

Brush roller speed:

-

0-1000r/min

-

Alternating speed:

-

0-35r/min

-

Rated voltage:

-

AC 380V/50Hz

-

The weight:

-

1500kg

-

Processing range:

-

W:900mm;H:80mm

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

EJON

-

Marketing Type:

-

Hot Product

-

Power (kW):

-

5

-

Weight (KG):

-

1100

-

Applicable Industries:

-

Laser cutting parts, Flame cutting parts, Precision sheet parts, metal sheet parts, stamping parts, automatic steel plate

-

Product name:

-

Automatic Metal Deburring Machine

-

Usage:

-

All flat metal

-

After-sales Service Provided:

-

1 Year

-

Maximum machining height:

-

80mm

-

Brush roller diameter:

-

300mm

-

Brush roller speed:

-

0-1000r/min

-

Alternating speed:

-

0-35r/min

-

Rated voltage:

-

AC 380V/50Hz

-

The weight:

-

1500kg

-

Processing range:

-

W:900mm;H:80mm

FEATURES AT A GLANCE

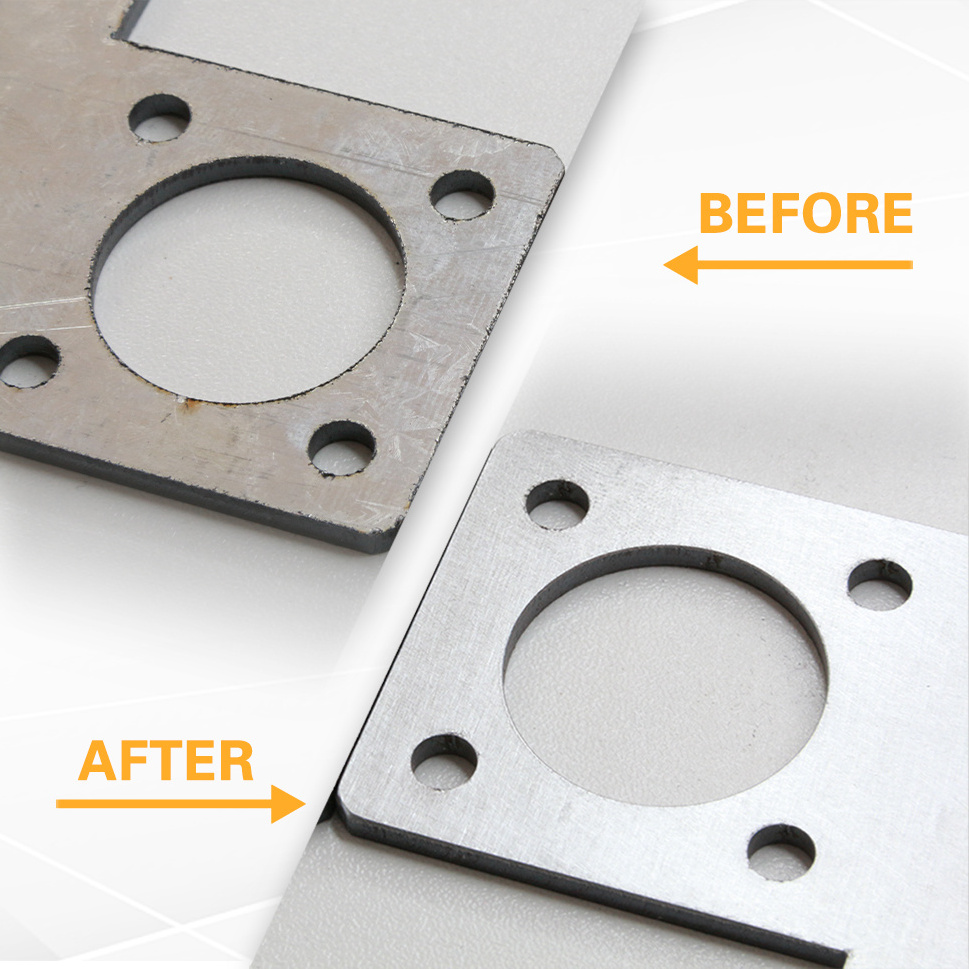

Polishing Effect

BEFORE

AFTER

BEFORE

AFTER

Our Advantages

TRADITIONAL METHOD

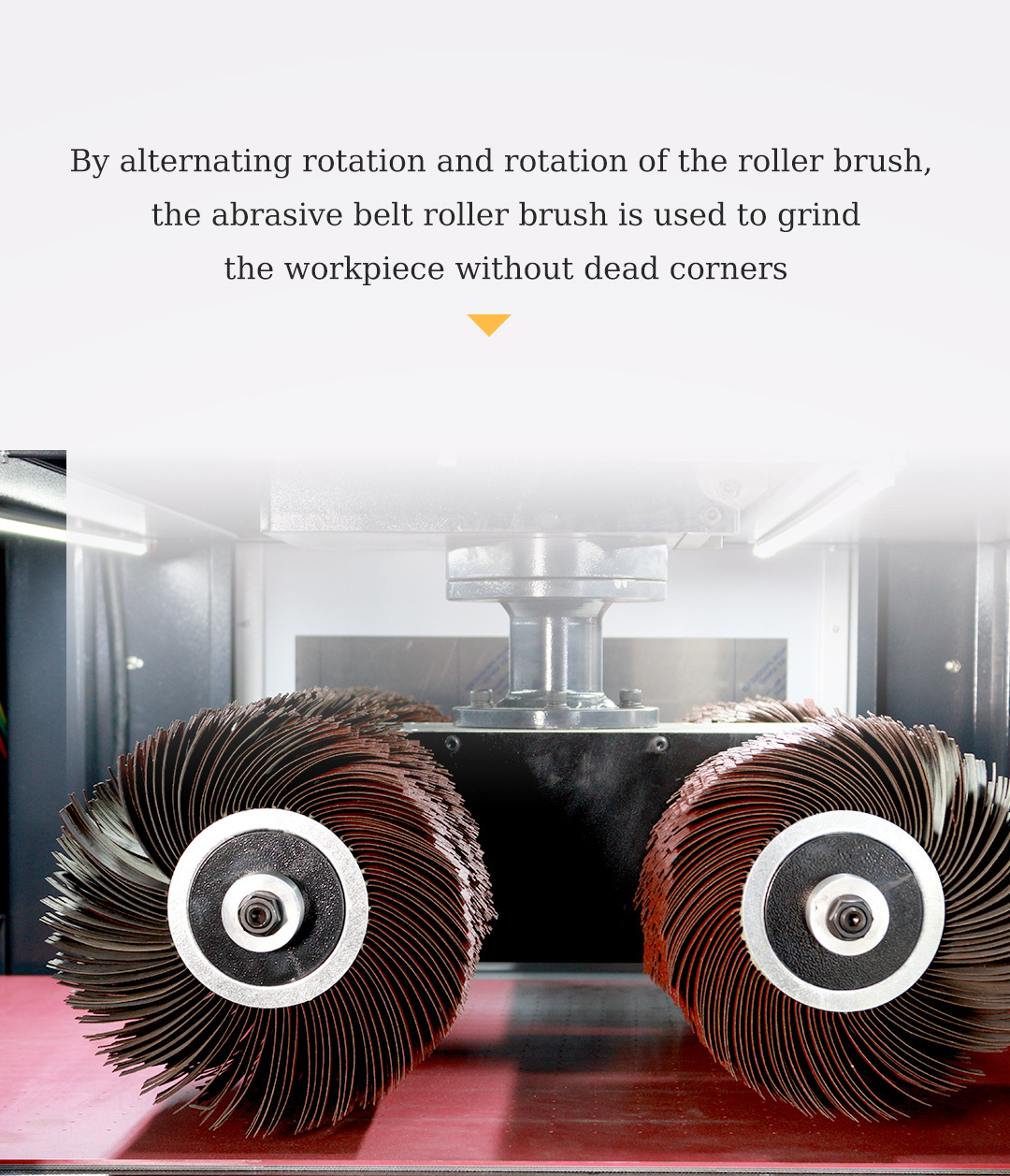

Manually apply angle grinder and chamfering machine, the process quality is unstable,

the chamfer is inconsistent, the edge is uneven, and it is easy to cause damage to the workpiece; The inner hole edge is not polished properly, resulting in machining dead corners.

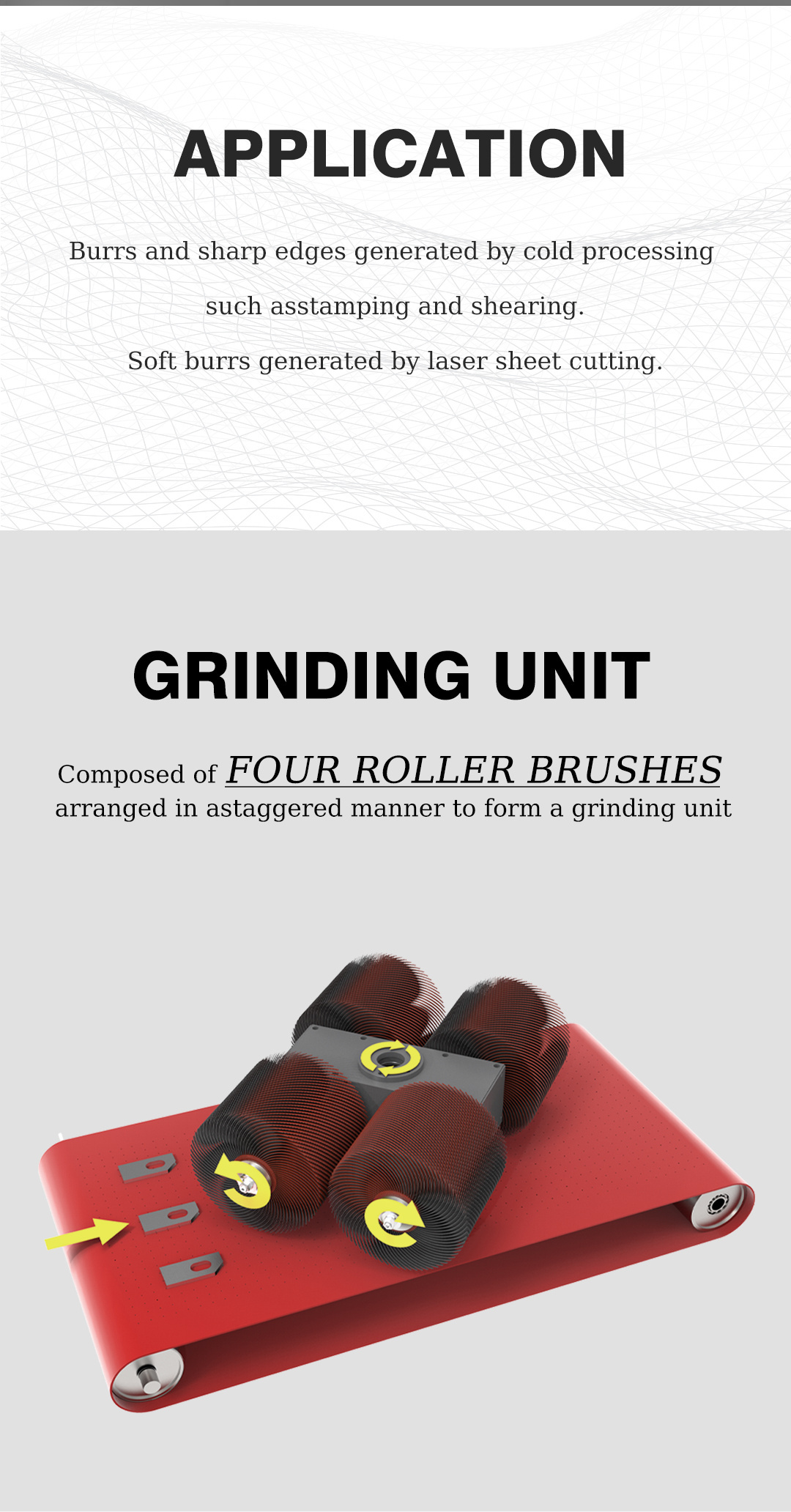

DEBURRING MACHINE SOLUTION

The deburring machine does 360-degree omni-directional machining without dead corner, and the inner and outer edges are fully covered; can achieve uniform chamfering, consistent angles, smooth edges and no harm to the workpiece.

TRADITIONAL METHOD

Manual operation can only process one workpiece each time.

When chamfering machine is used for larger workpieces, the operation is slow, and for oversized/ overlong workpieces need two people to work together, which has low efficiency and high labor cost.

DEBURRING MACHINE SOLUTION

The maximum transmission width of the deburring machine is 900 mm, and multiple workpieces can be placed at the same time for batch uninterrupted processing, and the transmission speed (0.1~14 m/min) can be set according to the demand to achieve efficient production.

|

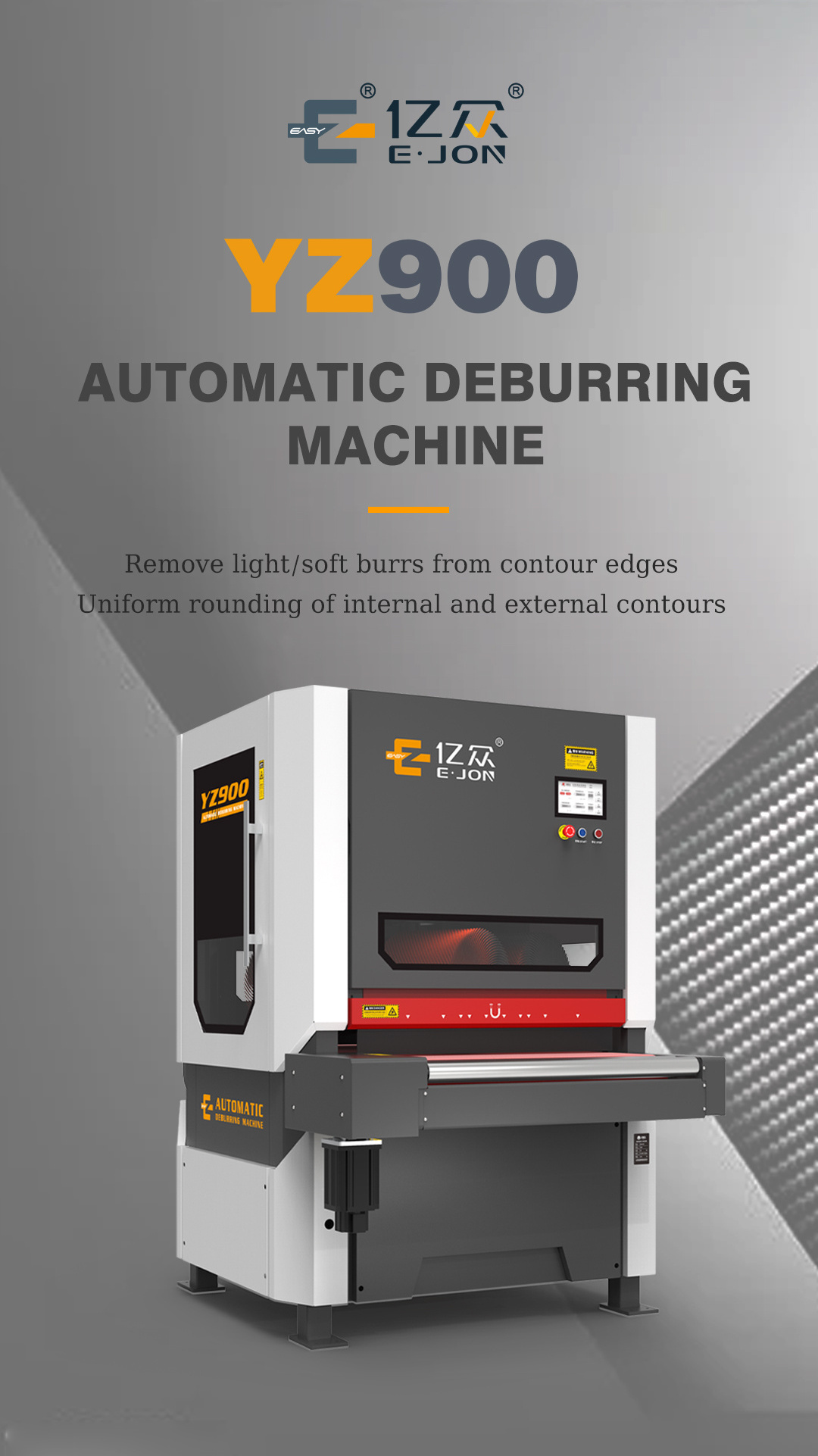

MAIN CHARACTERISTICS OF EJON YZ900

|

|

|

|

|

||||

|

1.

More convenient setting.

Integrated function setting+LED touch screen.

2.

Lower material cost.

Universal sand belt wheel can last 2~3 months; multiple sand belt wheels (80~150 molybdenum) are available.

3.

Safe.

No need to contact with materials during operation, metal debris is blocked in the cabinet and will not splash freely.

4.

Clean.

Dust and debris can be connected to the dust removal system.

5.

Multiple choices.

For magnetic-capable material processing, magnetic adsorption function is standard configuration, greatly reduce device power consumption; For materials that cannot be magnetically attracted, vacuum negative pressure workstation can be selected for adsorption processing.

6.

Parameters visual adjustment.

The grinding and stroke parameters can be freely adjusted visually, can only grind the contour and sharp edge of the workpiece without damaging the surface.

|

|

|

|

|

||||

Custom Structure

CLICK THE STRUCTURE THAT YOU'RE INTERESTED IN TO LEARN MORE

About Us

Exhibition

Recommend Products

Hot Searches