- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

1470*1100*1250mm

-

Weight:

-

320 kg

-

Marketing Type:

-

Factory Direct Supply

-

Product name:

-

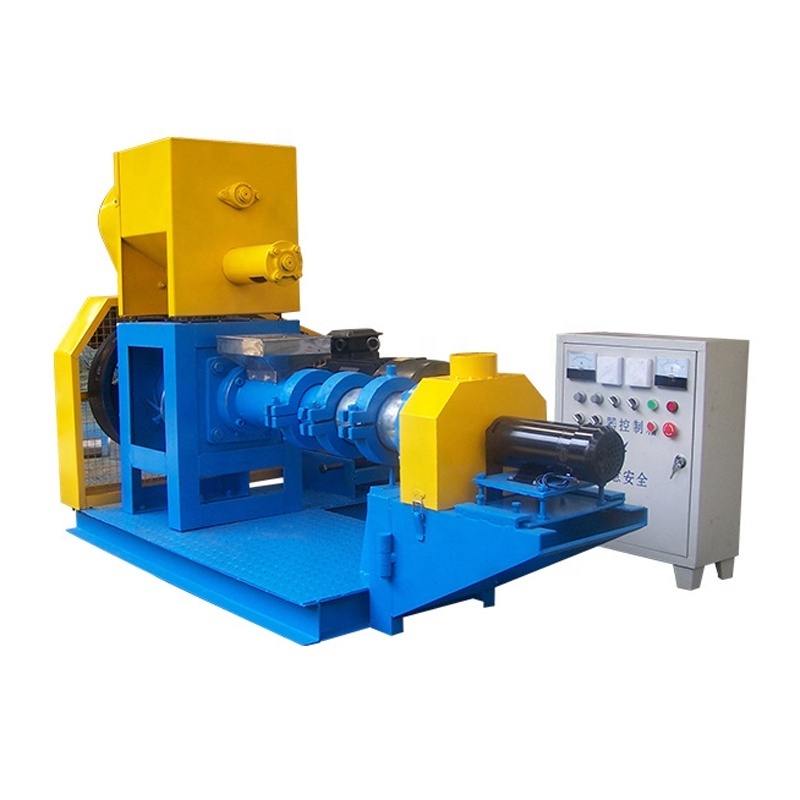

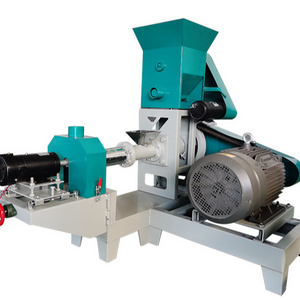

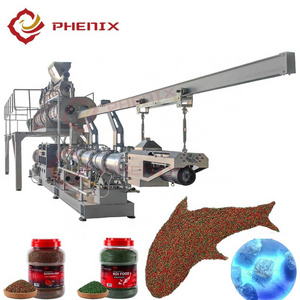

Pet Food Extruder Machine

-

Capacity:

-

40-4000kg/h

-

Function:

-

Producing Animal Feeds Pellets

-

Material:

-

Carbon Steel / 304 Stainless Steel

-

Product:

-

Pet Dog Cat Fish Food

-

Inverter:

-

Taiwan Delta

-

Feature:

-

High Efficiency Low Cost

-

After-sales Service:

-

Service Machinery Overseas

-

Processing Types:

-

Screw Extrusion

-

Advantage:

-

Easy Operation High Efficiency

Quick Details

-

Max. Capacity:

-

40-4000KG/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MAOSU

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

1470*1100*1250mm

-

Weight:

-

320 kg

-

Marketing Type:

-

Factory Direct Supply

-

Product name:

-

Pet Food Extruder Machine

-

Capacity:

-

40-4000kg/h

-

Function:

-

Producing Animal Feeds Pellets

-

Material:

-

Carbon Steel / 304 Stainless Steel

-

Product:

-

Pet Dog Cat Fish Food

-

Inverter:

-

Taiwan Delta

-

Feature:

-

High Efficiency Low Cost

-

After-sales Service:

-

Service Machinery Overseas

-

Processing Types:

-

Screw Extrusion

-

Advantage:

-

Easy Operation High Efficiency

Top quality fish feed pellet making machine floating fish feed extruder

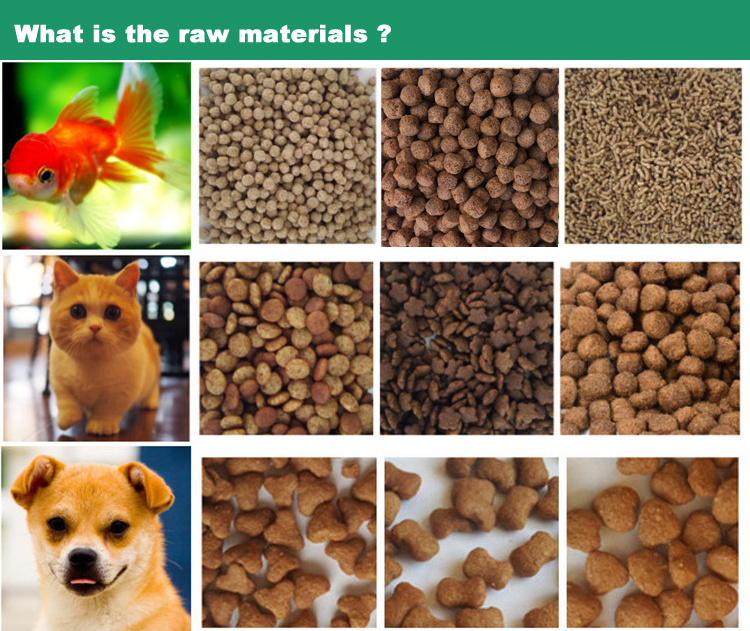

Pet food extruder is widely used for process all kinds of grains into high-grade aquatic feed pellet for fish,catfish,shrimps,crab.It also can make pet feed for

dog,cat ,chicken,crow, birds, poultry,pig,goat,etc with different shape and chicken feed.The final feed pellets have unique shape and good taste,high nutrition and smooth textures

1).

Raw materials

like f

lour,corn meal,soybean meal,maize meal ,meat meal,bone meal,fish meal

,vitamin

etc.

(2).

Raw materials Powder Size: 60-80

Mesh.

(3).

Raw materials moisture content: 20-

25

%.

(4)

. Diameter of Final Pellets:

1

mm-1

5

mm (Optional).

(5).

Length of the pellets can be adjustable by control the cutting knife

Dry type extruder specification:

| Model |

Capacity (kg/h) |

Main power (kw) |

Feeding power (kw) | Screw diameter (mm) |

Cutting power (kw) |

| DGP-40 | 40-60kg/h | 7.5kw | 0.4kw | Φ 4 0mm | 0.4kw |

| DGP-50 | 60-80kg /h | 11kw | 0.4kw | Φ 5 0mm | 0.4kw |

| DGP-60 | 100-150kg /h | 15kw | 0.4kw | Φ 6 0mm | 0.4kw |

| DGP-70 | 180-250kg /h | 18.5kw | 0.4kw | Φ 7 0mm | 0.4kw |

| DGP-80 | 300-350kg /h | 22kw | 0.4kw | Φ 8 0mm | 0.6kw |

| DGP-100 | 400-450kg /h | 37kw | 1.1kw | Φ 9 0mm | 0.6kw |

| DGP-120 | 500-700kg /h | 55kw | 1.1kw | Φ 12 0mm | 1.5kw |

| DGP-135 | 800-1000kg /h | 75kw | 1.1kw | Φ 133 mm | 2.2kw |

| DGP-160 | 1200-1500kg /h | 90kw | 1.5kw | Φ 155 mm | 2.2kw |

| DGP-200 | 1800-2000kg/h | 132kw | 1.5kw | Φ 195 mm | 3.0kw |

Wet type extruder specification:

| Model |

Output (kg/h) |

Main Power (kw) |

Feed Power(kw) |

Screw dia (mm) |

Cut power (kw) |

Conditioner power(kw) |

| DSP60 | 180-200 kg/h | 15 | 0.4 | 60 | 0.4 | 0.75 |

| DSP70 | 250-300 kg/h | 18.5 | 0.6 | 70 | 0.6 | 1.1 |

| DSP80 | 350-400 kg/h | 22 | 1.1 | 80 | 0.75 | 1.5 |

| DSP90 | 500-600 kg/h | 30 | 1.1 | 90 | 1.1 | 2.2 |

| DSP100 | 600-700 kg/h | 37 | 1.1 | 100 | 1.1 | 2.2 |

| DSP120 | 700-800 kg/h | 55 | 1.1 | 120 | 1.5 | 2.2 |

| DSP135 | 1000-1200 kg/h | 75 | 1.5 | 135 | 2.2 | 3.0 |

| DSP160 | 1800-2000 kg/h | 90 | 2.2 | 160 | 2.2 | 4.0 |

| DSP200 | 3000-4000 kg/h | 132 | 2.2 | 200 | 3.0 | 5.5 |