- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Promake

-

Dimension(L*W*H):

-

custom made

-

Weight (KG):

-

500

-

Keywords:

-

Fillng Machine

-

Type:

-

Filling Machine

-

Material:

-

Stainless Steel 304/316

-

Function:

-

Bottle Filling

-

Filling range:

-

2-50ml 10-150ml 30-300ml 50-500ml 100-1000ml

-

Filling speed:

-

can be customization

-

Application:

-

Machinery & Hardware

-

Packaging Material:

-

Wood

Quick Details

-

Production Capacity:

-

80-100 pcs

-

Automatic Grade:

-

fully automatic, Automatic

-

Driven Type:

-

Electirc

-

Voltage:

-

220V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Promake

-

Dimension(L*W*H):

-

custom made

-

Weight (KG):

-

500

-

Keywords:

-

Fillng Machine

-

Type:

-

Filling Machine

-

Material:

-

Stainless Steel 304/316

-

Function:

-

Bottle Filling

-

Filling range:

-

2-50ml 10-150ml 30-300ml 50-500ml 100-1000ml

-

Filling speed:

-

can be customization

-

Application:

-

Machinery & Hardware

-

Packaging Material:

-

Wood

Specification

Attention:

1. All prices and parameters shown above are nonstandard. If you want to know more information, please click "Contact

Supplier" to send us an email.

2.

Due to time lag difference, we suggest that you can choose to send us an inquiry in Alibaba.com,or email us.

3. When sending us an inquiry or message, please tell us your email or WhatsApp /

WeChat, etc. so that our sales manager can quickly communicate with us You get in touch.

Product Paramenters

|

item

|

value

|

|

Type

|

four heads Filling Machine

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms,cosmetic

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts

|

|

Application

|

Machinery & Hardware cosmetic

|

|

Automatic Grade

|

Automatic

|

|

Voltage

|

AC 220V 50Hz

|

|

Place of Origin

|

China

|

|

Weight

|

500KG

|

|

Certification

|

CE

|

|

Warranty

|

1 Year

|

|

Filling Material

|

Beer, Other, Milk, Water, Oil, Juice, can be customization

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Core Components

|

Motor

|

|

Material

|

Stainless Steel 304/316

|

|

Function

|

Bottle Filling

|

|

Filling range

|

120ml (can be customized according to requirements)

|

Application

1. Daily Chemical & Cosmetics Industry:

such as baby cream, skin cream face cream, shaving cream, toothpaste, cold cream, sunscreen cream,face cleanser, moisture cream, detergent, shampoo etc;

2. Food Industry:

Sauce, cheese, nutrition, infant food, chocolate, sugar , ketchup , mayonnaise, peanut butter, hot sauce peanut oil

and so on

;

3. Chemical Industry:

Latex, sauce, paints, coatings, resins, adhesives, lubricants

, emulsions, ointments, syrup, liquid. etc;

Details Images

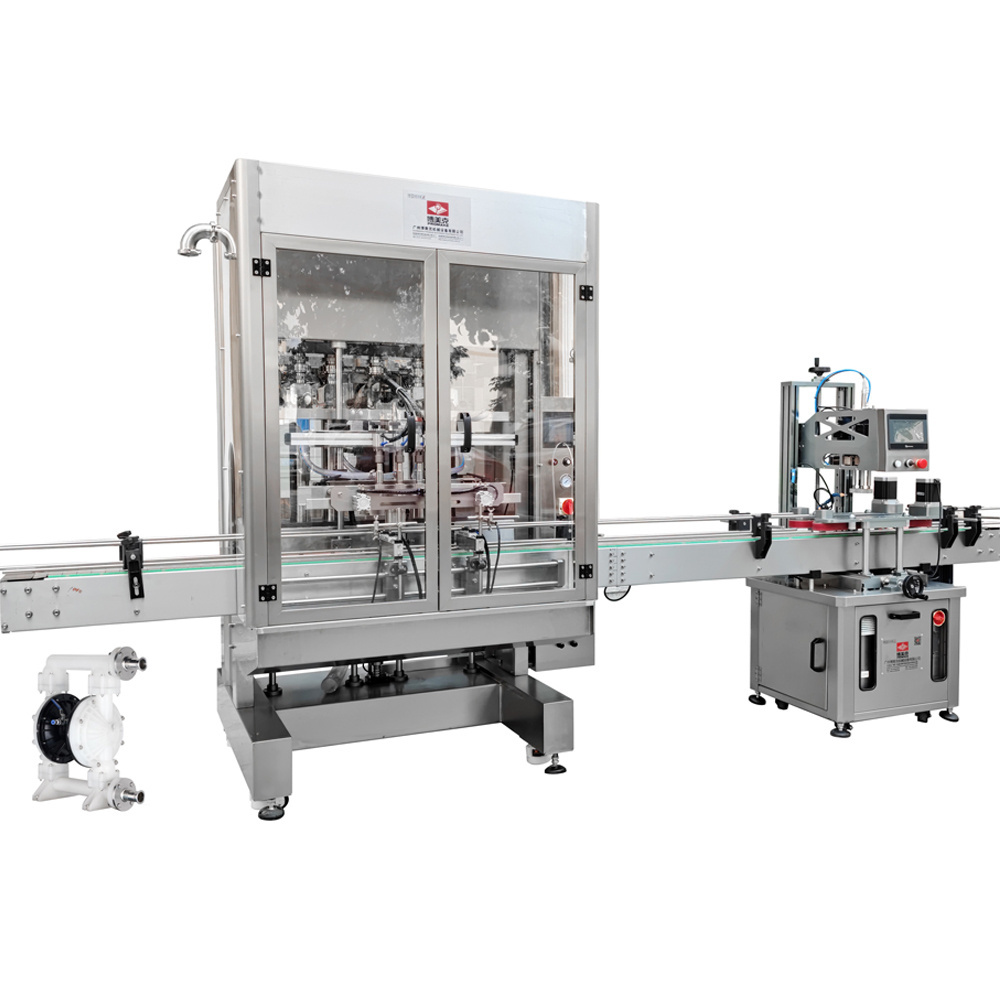

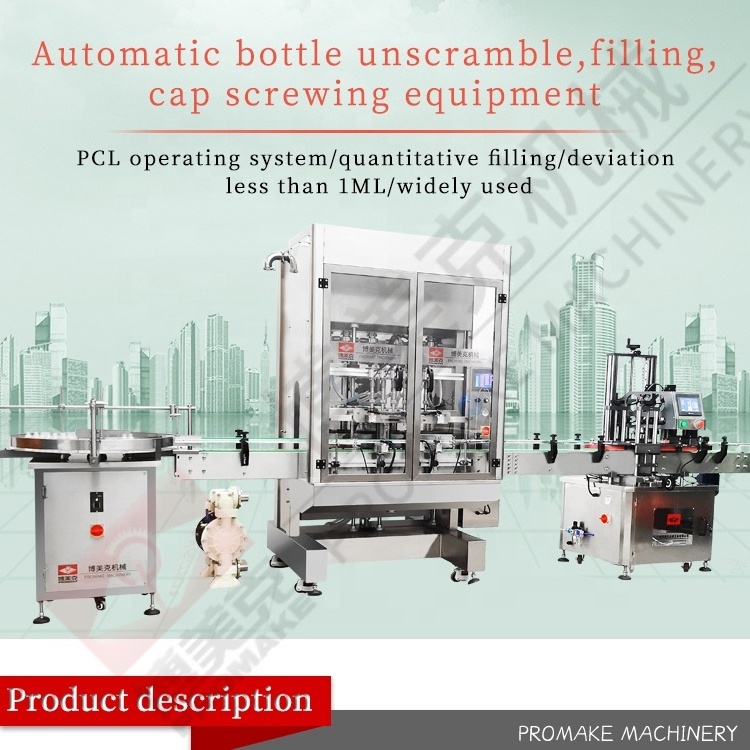

Features:

1.Working method: Using piston type or servo type (customer's choice), quantitative cylinder filling, automatic bottle feeding, automatic filling, equipped with automatic feeding system.

2.Production capacity: 120ml volumetric bottle production capacity can reach: 80-100pcs/min ((Data parameters: based on 25.C, viscosity 10pa.s shower gel as the test standard, the customer needs to provide sufficient packaging materials for more than 10 minutes of operation before leaving the factory carry out testing).

3.Features: It adopts a separate photoelectric system for feeding and unloading bottles, a mechanical structure with upper feeding and no one-way valve, and an oversized air storage tank at the bottom to ensure efficient and stable continuous production of the machine.

4.Convenience: The adjustment mechanism is designed to be as large as possible (including standard 114 widened conveyor belt, handwheel lifting adjustment device, handwheel overall adjustment device, single-head fine-tuning device, etc.) to adapt to the rapid replacement of various bottle types.

5.Control: Adopting a humanized touch human-machine interface, fully considering the ability of personnel with various qualities to accept automatic machinery, a guided adjustment module, a fault query module, etc. are added to the human-machine interface to facilitate operation and maintenance.

Hot Searches