- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

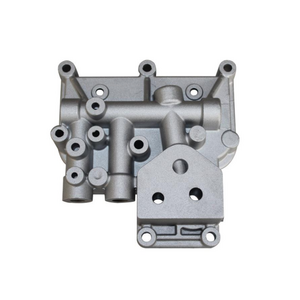

precision casting

-

Brand Name:

-

QH

-

Product name:

-

Customized machinery parts non standard steel casting products

-

Application:

-

Machinery Components

-

Material:

-

carbon steel

-

Process:

-

Lost wax investment casting+CNC machined

-

Heat Treatment:

-

Quench and temper by 2 set mesh belt furnaces

-

Surface Treatment:

-

Shot blasting+Assembling

-

Machining Facility:

-

50+ Machining centers,60+CNC machines

-

Inspection:

-

MT/UT/RT/100% visual+100%gage/CMM

-

Standard:

-

ASTM. AISI. DIN. BS. JIS. NF. AS.

-

Certification:

-

IATF16949/ISO14001

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Stainless steel, Steel Alloys

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

precision casting

-

Brand Name:

-

QH

-

Product name:

-

Customized machinery parts non standard steel casting products

-

Application:

-

Machinery Components

-

Material:

-

carbon steel

-

Process:

-

Lost wax investment casting+CNC machined

-

Heat Treatment:

-

Quench and temper by 2 set mesh belt furnaces

-

Surface Treatment:

-

Shot blasting+Assembling

-

Machining Facility:

-

50+ Machining centers,60+CNC machines

-

Inspection:

-

MT/UT/RT/100% visual+100%gage/CMM

-

Standard:

-

ASTM. AISI. DIN. BS. JIS. NF. AS.

-

Certification:

-

IATF16949/ISO14001

Customized machinery parts non standard steel casting products

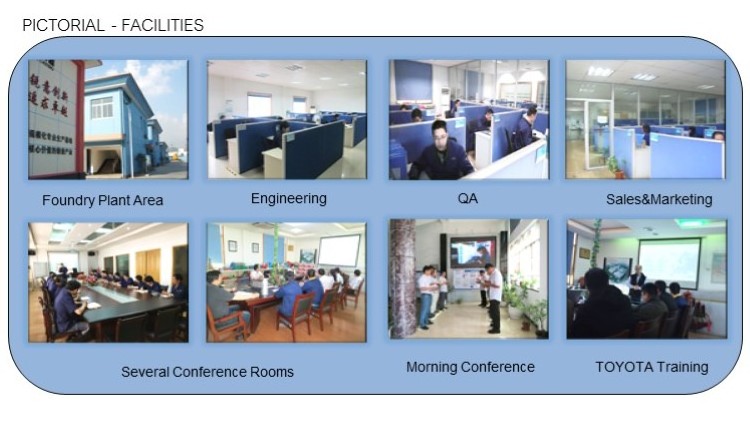

1. Company Image:

2. Overview of Factory---Huawei Investment Casting:

|

3. Overview of Factory---Qianhao Machining (predecessor is Longxing machinery ):

|

4. Our Mission:

Create superior value for our customers, partners, employees

To become the most respected and successful metal forming and processing company in the world

5. Our Values:

-

Honesty and Practicality

- Persevering Unremittingly

- Teamwork Spirit

- Achieving Greatness

- Expanding our offerings to enable customer success through integrated and differentiated solutions

6. Product Description:

| Material | Carbon steel, Alloy steel, stainless steel, cast iron, aluminum alloy, copper alloy |

| Process | Lost wax casting + cnc machining |

| Casting dimension tolerance | CT7-CT8 |

| Casting surface roughness | Ra 12.5um |

| Casting weight range | 0.1-100kg |

| Casting Size | Max linear size:1200mm, Max diameter size: 600mm |

| Machining Precision | Positioning accuracy 0.008mm, Rep. position. accuracy 0.006mm |

| Machining surface roughness | Ra0.8~6.3um |

| Max Travel Of Spindle | 1800mmx850mmx700mm |

| Max Turning Diameter | 1000mm |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR....... |

| Surface treatment | KTL(E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Wet Painting, Hot galvanizing,Powder coating, Nickel plating, Anti rust dip |

| Service available | OEM & ODM |

| Quality control | 0 defects,100% inspection before packing |

| Application | Train & railway, automobile& truck, construction machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and so on. |

7. Product Profile:

| 1. Marterial percentage |

alloy steel:45% carbon steel:35% stainless steel:10% iron:10% |

| 2. Casting weight percentage |

0.1-5kg:40% 5-20kg:30% 20-40kg:20% above 40kg:10% |

| 3. Industry percentage |

Components for Rail: 15% Components for automobile: 25% Components for construction equipment: 20% Components for Material Handling Equipment:20% Components for agricultural machinery: 10% Other machinery compponents: 10% |

| 4. Globa market share |

United States:30% Europe:35% Japan& Korea:15% Domestic market:15% Other:5% |

| 5. Production capacity |

Production Capacity: 20,000 tons / year The Current Production Output: 15,000 tons / year Open Capacity Percentage: 25% |

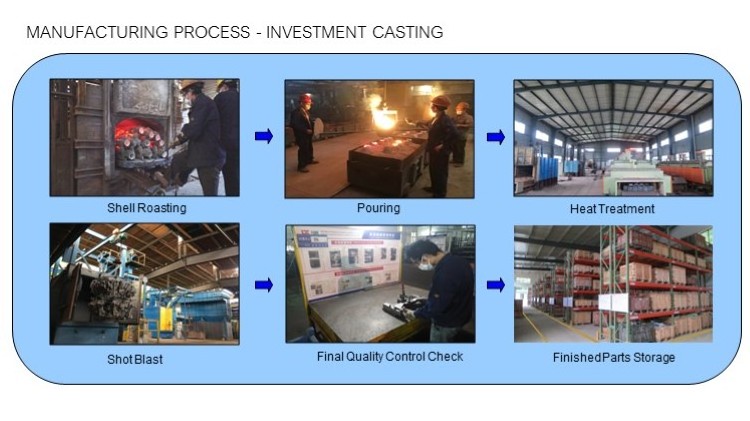

8. Manufacturing Process:

Process design⇒ Tooling making ⇒ Wax injection ⇒Wax pattern assembly⇒ Mold preheat ⇒ Wax removal ⇒Stuccoing ⇒Dipping Casting⇒ Mold shake out ⇒Work piece cut-off ⇒ Grinding ⇒ Pack& transport ⇒ Final inspection ⇒Machining ⇒ Heat treatment

9. Key Casting and Machining Equipment:

10. Major Machining Equipment List:

| Machining Capabilities | |

| Turn Center 3 Axis: 1 | CNC Lathe: 35 |

| Vert Machine Cntr 4 Axis: 49 | Oblique Guide CNC Lathe: 2 |

| Horizontal Machine Cntr 4 Axis: 1 | Engine Lathe: 6 |

| CNC Milling: 10 | Special Lathe: 5 |

| Vert Lift Milling : 4 | Radial; Drilling : 4 |

| Universal Milling : 2 | CNC Porous Drilling : 6 |

| Plane Milling : 2 | Special CNC Drill Lathe : 6 |

| Face Milling: 3 | Cylindrical Drilling: 11 |

11. We provide various test facilities as mentioned under:

|

1. Chemical analysis |

| 2. Tensile strength |

| 3. Elongation rate |

| 4. Shrinkage rate |

| 5. Impact test |

| 6. Harness test |

| 7. Metallography |

| 8.Non-destructive tests(including dye-penetrant, ultrasonic, magnetic particle and radiography) |

| 9. Surface roughness test |

| 10.CMM test |

| 11.Chemical & Mechanical |

| 12.3D Scanning |

| 13.Yield Strength |

| 14.Dimensional |

| 15.Microscopic Measurement |

12. Key Testing Equipment:

13. APQP and Inspection Report:

|

APQP-Casting

|

|

APQP-Machining

|

|

Inspection Report-Casting

|

|

Inspection Report-Machining

|

|

Other Quality Document

|

14. Competition advantages:

| Advantages 1:High Engineering and Technical Capability |

|

| Advantages 2: Advanced Inspection Equipment,Process & Strong Quality Assurance Capacity |

|

| Advantages3: Great Customer Service |

|

| Advantages 4: Powerful Deep-processing capability and commitment are important core competitive advantage different from others in the industry |

|

15. Contact information: