- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunzhi

-

Production Capacity:

-

10-15m3/h

-

Dimension(L*W*H):

-

2020*650*1150mm

-

Power:

-

4kw

-

Voltage:

-

380V/220V

-

Speed:

-

48r/min

-

Screen size:

-

0.3mm

-

Screen material:

-

SS

-

Other name:

-

cow chicken sheep pig horse manure separator equipment

-

Color:

-

Customized

-

Certification:

-

CE ISO

Quick Details

-

Weight (KG):

-

370

-

Type:

-

Screw type

-

Use:

-

Solid liquid separating,

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunzhi

-

Production Capacity:

-

10-15m3/h

-

Dimension(L*W*H):

-

2020*650*1150mm

-

Power:

-

4kw

-

Voltage:

-

380V/220V

-

Speed:

-

48r/min

-

Screen size:

-

0.3mm

-

Screen material:

-

SS

-

Other name:

-

cow chicken sheep pig horse manure separator equipment

-

Color:

-

Customized

-

Certification:

-

CE ISO

1.

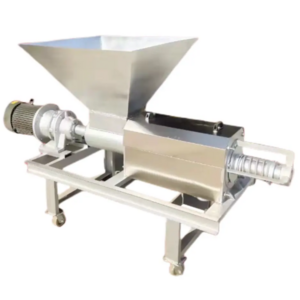

Introduction of cow manure dewatering machine:

Spiral extrusion type solid-liquid separator is a new mechanical dewatering equipment developed by our company by referring to various advanced dewatering equipment at home and abroad and combining with our own dewatering equipment r&d and manufacturing experience.Spiral extruding solid-liquid separator is mainly composed of control cabinet, pipeline, body, screen, extruding screw, reduction motor, counterweight, unloading device and other parts, this equipment is widely used, and has been recognized by the majority of users in the market.

2.Working principle of cow manure dewatering machine:

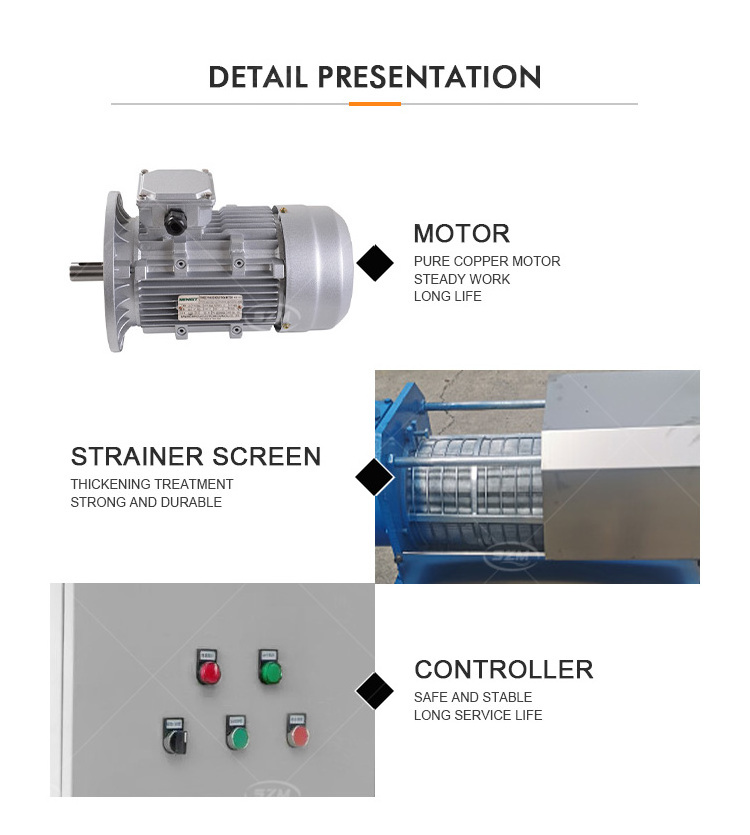

The principle of solid-liquid separator is spiral extrusion solid-liquid separation technology.The main components are: body, screen, extrusion and stranding, reduction motor, unloading device and other components.

After the cutting feed pump pumps the mixture to the solid-liquid separator through the pipeline, the separator starts, and the mixture is gradually pushed forward to the front of the body by squeezing the stringer.

At the same time, the pressure of the leading edge is constantlyincreased, forcing the water in the material to extrude the screen and flow out of the drain pipe.The work of the extruder is continuous, the material is continuously pumped into the body, the leading edge of the pressure is increasing, when to a certain extent, the discharge port will be opened, extrusion extrusion port, to achieve the purpose of extrusion.In order to grasp the speed and water content of the discharge, the control device in front of the main engine can be adjusted to achieve a satisfactory and appropriate discharge state.

The principle of solid-liquid separator is spiral extrusion solid-liquid separation technology.The main components are: body, screen, extrusion and stranding, reduction motor, unloading device and other components.

After the cutting feed pump pumps the mixture to the solid-liquid separator through the pipeline, the separator starts, and the mixture is gradually pushed forward to the front of the body by squeezing the stringer.

At the same time, the pressure of the leading edge is constantlyincreased, forcing the water in the material to extrude the screen and flow out of the drain pipe.The work of the extruder is continuous, the material is continuously pumped into the body, the leading edge of the pressure is increasing, when to a certain extent, the discharge port will be opened, extrusion extrusion port, to achieve the purpose of extrusion.In order to grasp the speed and water content of the discharge, the control device in front of the main engine can be adjusted to achieve a satisfactory and appropriate discharge state.

3.Where to use?

1) Before composting, the moisture of manure should be controlled at 50%. This machine can help you in a short time.

2) You want to make pellets, but you are worried about the high water content of your raw materials.

3) You want to sell manure as dried manure.

4) There is a pile of sludge, wet powder, wet tofu residue and other high-liquid solids that cannot be processed.

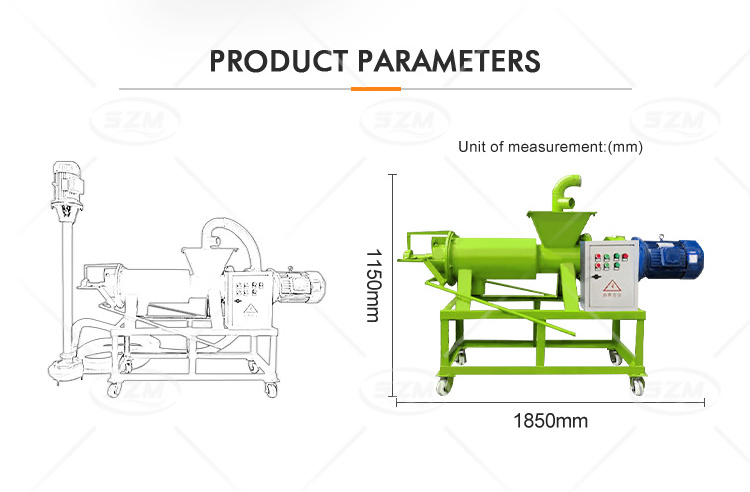

|

Model

|

Capacity (m3/h)

|

Power (kw)

|

Dimension (mm)

|

|

SZTSJ-180

|

10-15

|

4

|

1850*650*1150

|

|

SZTSJ-230

|

15-20

|

5.5

|

1850*800*1150

|

In order to better ensure the safety of your goods, Henan Shunzhi Machinery Equipment Co., Ltd. will provide professional, environmentally friendly, convenient and efficient packaging services.

Henan Shunzhi Machinery Equipment Co., Ltd. is a leading brand of fertilizer equipment in China. Henan Shunzhi is an environmentally friendly high-tech enterprise specializing in the R&D and manufacturing of organic fertilizer and compound fertilizer equipment. Henan Shunzhi was established in 1993. The factory is located in Zhengzhou City, Henan Province. All new and old customers are welcome to visit the factory at any time!

Pre-sale Service:

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician;

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

After-sales Service:

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service

7.Providing technical exchanging.s.

Question

1. Are you factory or trade company?

Answer

1:

We are manufacturer, we also supply trade service.

Question

2.

What about your price?

Answer

2:

We always supply the products with low price, because we believe this is the way to build long-term business and earn good reputation.Our price is 3%-5% lower than the average market price.

Question

3.

What payment terms do you accept?

Answer

3:

Welcome clients to place orders by Alibaba Trade Assurance! Other payment ways such as T/T, L/C, D/P, etc can be negotiated.

Question

4.

How about your delivery time?

Answer

4:

Generally, it will take 15-20 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Question

5.

what will you do if the machine is broken down?

Answer

5:

The Products warranty is one year. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. For those wear parts, we guarantee the high quality parts for long-term supply.

Question

6.

What can you buy from us?

Answer

6:

Organic fertilizer plants, compound fertilizer plants, nitrogen-phosphorus-potassium fertilizer plants, granulators, composters and other types of fertilizer machines.

Hot Searches