- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800*6600

-

Year:

-

2023

-

Power (kW):

-

23 kW

-

Weight (KG):

-

25000 KG

-

Application:

-

plastic recycling to fuel oil machine

-

End product:

-

Fuel Oil Steel Carbon Back

-

Machine structure:

-

horizontal

-

Heating Method:

-

Directly Heating

-

Cooling system:

-

Water Cooling Device

-

Heating fuel:

-

Wood Coal Gas Oil

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huayin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2800*6600

-

Year:

-

2023

-

Power (kW):

-

23 kW

-

Weight (KG):

-

25000 KG

-

Application:

-

plastic recycling to fuel oil machine

-

End product:

-

Fuel Oil Steel Carbon Back

-

Machine structure:

-

horizontal

-

Heating Method:

-

Directly Heating

-

Cooling system:

-

Water Cooling Device

-

Heating fuel:

-

Wood Coal Gas Oil

waste plastic tyre pyrolysis plant and refinery cost fast installation

With the increasing awareness of environmental protection in the world, the harmless and resourceful disposal of waste tires/plastic has become an important trend. The waste plastic /tyre recycle to fuel oil machinery is designed to process the waste into valuable products -industrial fuel oil, carbon black, and steel wire through catalytic cracking technology. This green technology has created good economic and social benefits.

Specification of waste plastic pyrolysis plant and refinery

|

Unit capacity

|

5-15tons

|

|

Production mode

|

Batch type

|

|

Overall Dimension

|

35M*12M*8M

|

|

Total Weight

|

30-45Tons

|

|

Internal Volume of Reactor

|

22.8-49.85CBM

|

|

Condensing System

|

Horizontal condenser & Square box condenser

|

|

Emission Control System

|

Water film scrubber & Stainless steel scrubber plus internal filters

|

|

Heating system

|

Oil burners and gas burners

|

|

Feeding System

|

Hydraulic feeder

|

|

Discharging System

|

Side discharging : U -shape screw conveyor

|

|

Output Products

|

Application

|

|

Fuel Oil

(40%-55%) |

1. Used as the heating material and sell it to cement factories, glass factories, ceramic factories, electric power factories, steel making factories, boiler factories, etc.

2. Used in heavy oil generator for electricity generation. 3. Deep process it into diesel oil with our distillation plant, color, and smell removal system, the final oil can be used in trucks, tractors, etc. |

|

Carbon Black (30%-35%)

|

Make it to pellet or briquette as heating material.

|

|

Steel Wire (10%-15%)

|

It's easy to sell to scrap metal dealers.

|

|

Flammable Gas (8%-10%)

|

1. Recycled into the furnace to heat reactor instead of coal/wood/oil/natural gas.

2. Storage the exceed gas to restart the next batch. |

Input raw material

Input raw material : waste tyre ,rubber , plastic , pp, pe , ps , abs etc.

Output product : Pyrolysis oil , carbon black , and steel wire , syngas.

Capacity : 10kg , 750kg , 4ton , 5ton , 10ton , 15ton, 30ton , 50ton. support customization.

Output product

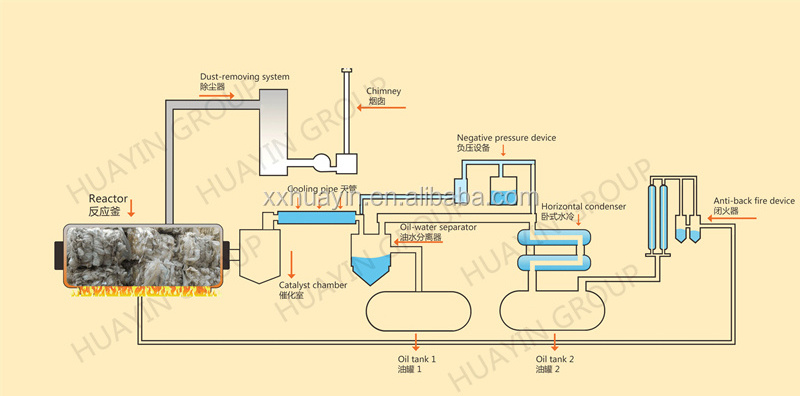

working process

Operation process of waste plastic pyrolysis plant

1. Loading the waste material into the pyrolysis reactor manually or with auto feeder.

2. Heating the pyrolysis reactor and producing oil.

3. The exhaust gas which can not be cooled to liquid oil will be recycled to heat the reactor. Smoke will be purified through strong and powerful dust removal device.

4. Cool the pyrolysis reactor after oil production is finished.

5. Discharging carbon black and steel wire.

1. Loading the waste material into the pyrolysis reactor manually or with auto feeder.

2. Heating the pyrolysis reactor and producing oil.

3. The exhaust gas which can not be cooled to liquid oil will be recycled to heat the reactor. Smoke will be purified through strong and powerful dust removal device.

4. Cool the pyrolysis reactor after oil production is finished.

5. Discharging carbon black and steel wire.

Installation cases

1.The material of the reactor is Q345R/Q245R boiler plate with 16/18mm thickness.

The rollers are engineered underfeeding port and oil outlet port which are external to the heating area to bring perfect rotating balance and longer service life.

2. Two devices to avoid backfire in production: oil-water separator and anti-back fire device.

2. Vacuum device makes the reactor work under ordinary pressure or negative pressure.

4. Temperature monitoring and Pressure gauge to monitor the pressure. If the pressure goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

2. Vacuum device makes the reactor work under ordinary pressure or negative pressure.

4. Temperature monitoring and Pressure gauge to monitor the pressure. If the pressure goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

5. The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by a powerful ceramic packing dust removal device, then can be released into the air through the chimney.

6. Carbon black will be discharged out in sealed condition to avoid pollution.

6. Carbon black will be discharged out in sealed condition to avoid pollution.

Our Advantages

Pyrolysis reactor : Made of Q245R steel plate , high pressure and temperature resistance. the main body of the complete line, the internal reactor is rotating when production,and the temperature inside is over 500℃. Because of the excellent insulation layer , the heating efficiency is high.

Square box condenser: It offers a long condensing distance of 120 meters in total. The pyrolysis gas produced from pyrolysis reactor enters the internal condenser pipes connected in series. The condensing process is fast and efficient. The diameter of condensing pipe not only brings larger heat exchange area, but also makes maintenance easier.

The stainless steel deduster is filled with ceramic filters inside, which brings it strong dust adsorption capacity and good dust control effect.

Carbon black discharging device

Auto feeder device

Profit analysis

Assumption

8 set of 15tons pyrolysis plant , processing 2,400 tons of used tire per month.

It produces 42% of oil , 30% of cabon black and 15% of steel wires from used tires.

Water consumption is 2 tons and electricity consumption is 300kwh each machine each working day.

Labor works 8 hours by 3 shifts. It needs 20 workers.

|

Cost

|

|

|

|

|||

|

Item

|

Unit price

|

Qty

|

Monthly amount

|

|||

|

Purchase of used tires

|

USD 100

|

2,400 tons

|

USD 240,000

|

|||

|

Water

|

USD 0.4

|

320 tons

|

USD 128

|

|||

|

Electricity

|

USD 0.13

|

48,000 kwh

|

USD 6,240

|

|||

|

Salary

|

USD 1,000

|

20 workers

|

USD 20,000

|

|||

|

Maintenance

|

|

|

USD 5,000

|

|||

|

Others

|

|

|

USD 5,000

|

|||

|

Total

|

|

|

USD 5,000

|

|||

|

Income

|

|

|

|

|||

|

Item

|

Unit price

|

Qty

|

Monthly amount

|

|||

|

Sales of oil

|

USD 650

|

1,008 tons

|

USD 655,200

|

|||

|

Sales of carbon black

|

USD 80

|

720 tons

|

USD57,600

|

|||

|

Sales of steel wire

|

USD350

|

360 tons

|

USD 126,000

|

|||

|

TOTAL

|

|

|

USD 838,800

|

|||

|

Profit

|

|

|

|

|||

|

Item

|

|

Monthly amount

|

|

|||

|

Profit before taxes

|

|

USD 562,432

|

|

|||

|

Profit to process each ton of used tires

|

|

USD 234

|

|

|||

Our Service

1. Huayin provides engineering design based on customers’ Help customers choose the most suitable models to recycle the waste.

2. We will send experienced engineer to customer’s site for guiding installation, commissioning and training the workers until the equipment runs stably.

3. Huayin provides one year warranty for each set of equipment and life -long maintenance service.

2. We will send experienced engineer to customer’s site for guiding installation, commissioning and training the workers until the equipment runs stably.

3. Huayin provides one year warranty for each set of equipment and life -long maintenance service.

Contact US

Established in 1993, Xinxiang HUAYIN Renewable Energy Equipment Co., Ltd is an environmental protection plant manufacturer integrating product R&D, design, production, marketing, installation and after-sales. HUAYIN Energy enjoys a technical and service team composed of more than 30 experienced engineers and a number of invention patents, CE, SGS, ISO9001 and ISO14001 certifications.

Our certificates

For more details informaiton about the pyrolysis machine ,welcome contact us !

Hot Searches