- Product Details

- {{item.text}}

Quick Details

-

Diameter of Movable Blade:

-

600mm

-

Production Capacity:

-

3t/h

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Name:

-

Latex Gloves Crusher Machine / Waste Tyre Cutting Machine

-

Speed of Main Shaft:

-

59r/min

-

Diameter of Movable Blade:

-

600mm

-

Production Capacity:

-

3t/h

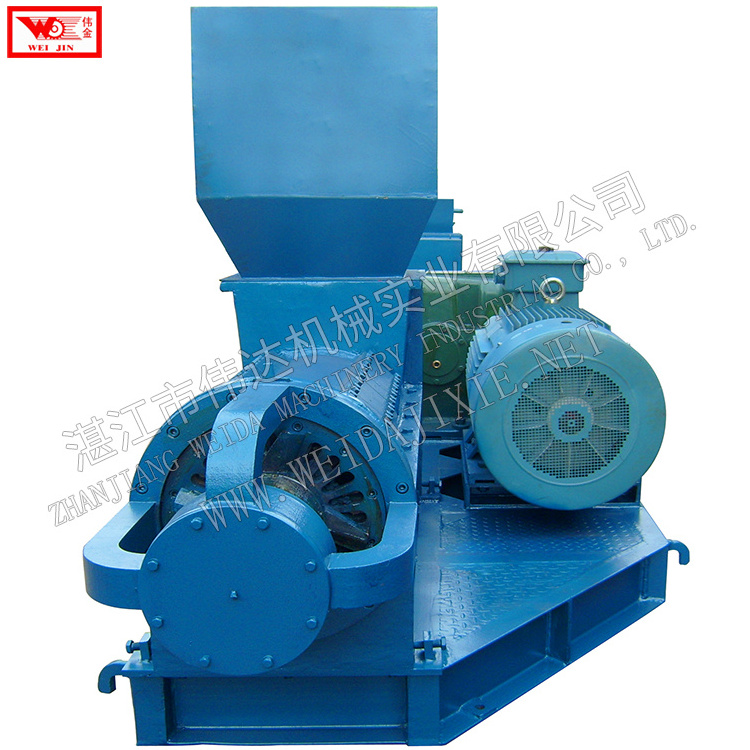

Rubber process machinery / Latex Gloves Crusher Machine / Waste Tyre Cutting Machine

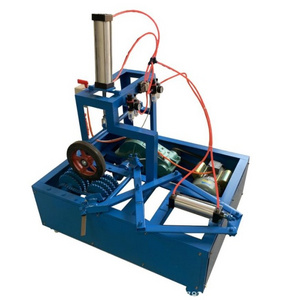

Working Principle:

This machine is mainly composed of the rubber blade, frame, cylinder and hydraulic system. Put the raw rubber block under the blade before working, which the blade would be down and cut off the rubber bale by the pressure force of cylinder.

Function:

The purpose of this machine is to cut off the natural rubber, compound rubber, reclaimed rubber or synthetic rubber blocks/bales into the required size rubber for further processing. This machine is more suitable for cutting the large rubber blocks/bales.

So far, the most common technologies have been used are open mill mixing and internal mixer mixing, which are called non-continuous mixing. Based on the advantages of both open mill and internal mixer, we have designed the “ screw mixing machine ” in continuous mixing method and of high efficiency with the strong points as follow:

1)It is efficient as it works continuously;

2)It does not result in power wasting as there is no idle-running;

3)It does not results in any working environmental impacts as the the process happens in the sealed main body of the machine;

4)It reduces the cost and increase the profit in operation as less power and fewer workers are required compared to those for open mill or for internal mixer.

5)It takes low labor intensity as there is only one worker needed in material feeding on the conveyor and qualified product is processed automatically.

It is a new type of mixing machine which is highly recommended in rubber product processing.

Model & Main Data

|

Model |

HL-250 |

HL-400 |

HL-500 |

HL-600 |

|

Rotating speed |

30r/min |

37r/min |

47r/min |

47r/min |

|

Power |

55kw |

160kw |

250kw |

315kw |

|

Capacity |

0.5t/h |

1t/h |

2t/h |

4t/h |

2004, it is the year that Zhanjiang Weida Machinery Industrial Co., Ltd. was founded in, but also the year that the Wei Da machinery with "Wei Jin" brand was born in.

As a manufacturing enterprise, Weida machinery has been committed to the design, development and production of natural rubber industry equipment, and is currently one of the world's professional hot work machinery manufacturing enterprises.

"To pursue quality, innovate continuously" is the enterprise philosophy that Weida machinery always keeps. Combine the excellent professional technology with the advanced industry production technology, customize equipment or production line configuration for customers to meet their actual needs and local market development trends, to maximize profits.

Each section of the rubber processing equipment adopts special selected refined materials, no marrer how from design to production, each link strictly follows the international general standard. Every detail is to strive for practical, refined, perfect, equipment quality is first-class.

The company is located in the beautiful southern coastal city-Zhanjiang. Here are pleasant beaches and delicious seafood, as well as a number of powerful scientific research and design teams of Weida Machinery. With more than ten years of experience in the industry, the technical personnel acutely be aware of market changes, pay attention to the integration of industry maturity technology at any time, continue to innovate, develop more natural rubber industry processing equipment suitable for the market demand. Due to excellent production technology and performance with high quality and efficiency, our products are also well known by Vietnam, Burma, Kampuchea, Thailand, Malaysia, Africa, Europe, South America and other countries and regions at home and abroad.

Different from similar enterprises, Weida machinery has also established a set of perfect after sales service system, including pre consultation, long-term tracking and maintenance, as well as after sales technical training and a series of innovative services.The added value of the product will be the highest and best.

We provide design and manufacturing services for different equipment and machines on request.