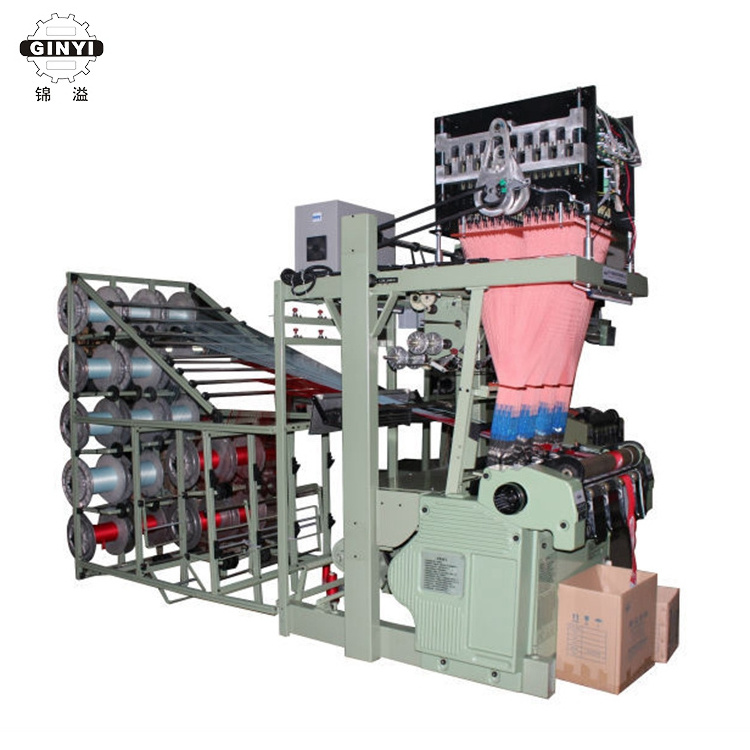

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

GinYi

-

Dimension(L*W*H):

-

180cm*115cm*270cm

-

Power:

-

1.5KW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Webbing machine:

-

Jacquard Loom

-

Heald frame:

-

8

-

Pick Repeat:

-

8-40

-

Max.Speed R.P.M:

-

750-850

-

Services:

-

Operation instruction&professional training

-

Packing:

-

Carton box(waterproof)

Quick Details

-

Type:

-

Jacquard Loom

-

Production Capacity:

-

1500-2000 for 20 hours

-

Application:

-

Belt

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

GinYi

-

Dimension(L*W*H):

-

180cm*115cm*270cm

-

Power:

-

1.5KW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Webbing machine:

-

Jacquard Loom

-

Heald frame:

-

8

-

Pick Repeat:

-

8-40

-

Max.Speed R.P.M:

-

750-850

-

Services:

-

Operation instruction&professional training

-

Packing:

-

Carton box(waterproof)

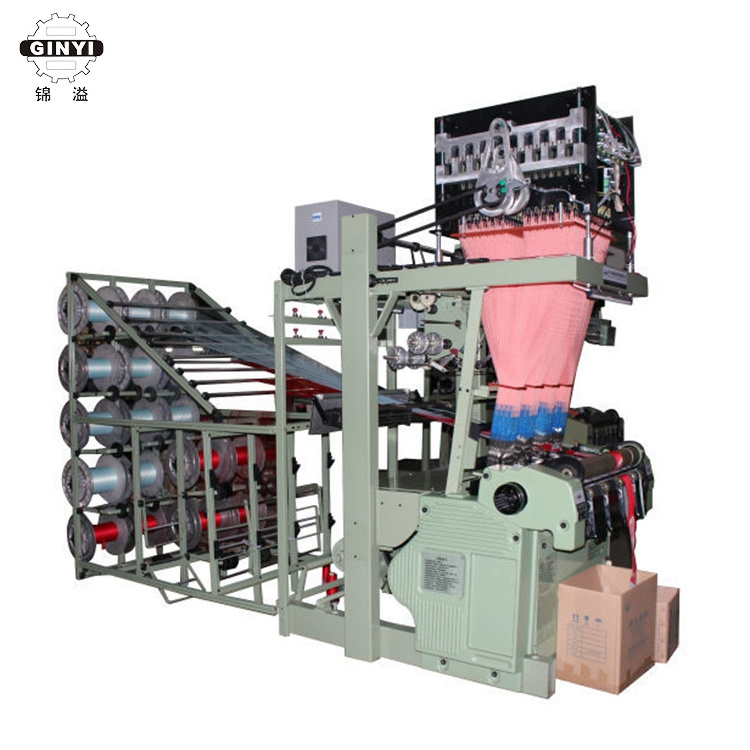

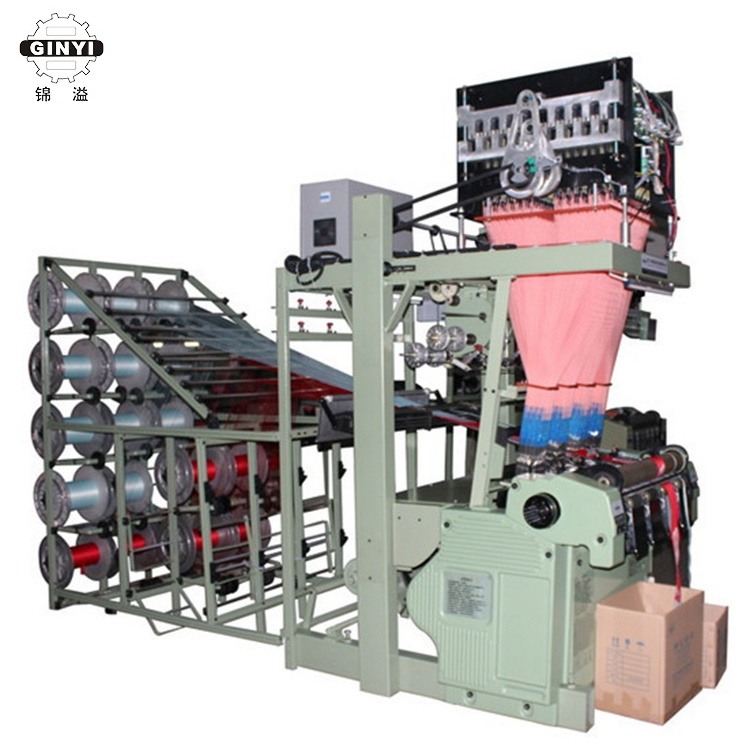

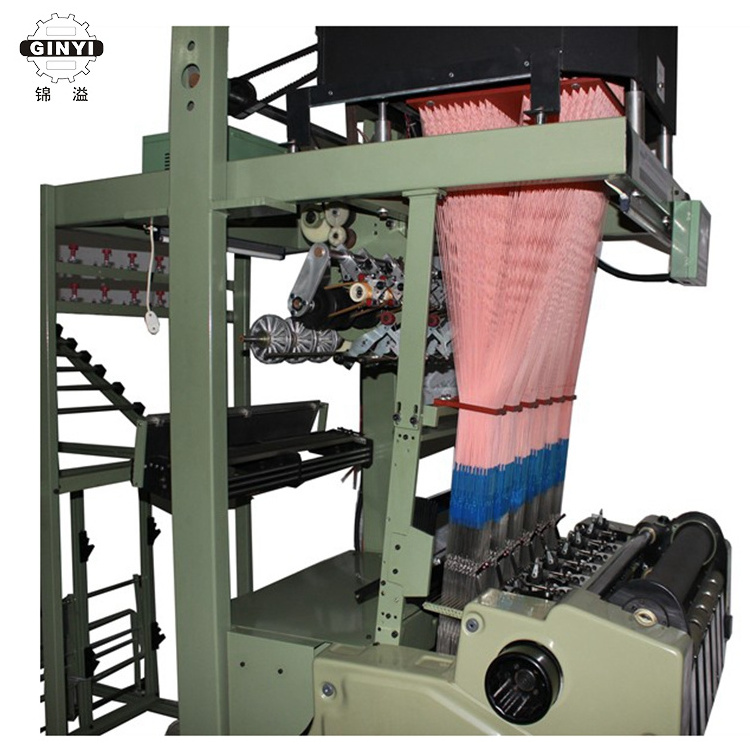

1.Specifications

|

Model |

GNC-4/80 |

|

Jacquard Needles |

240/480/640 |

|

Belt Numbers |

4 |

|

Reed Width(mm) |

80 |

|

Heald Frame |

8 |

|

Pick Repeat |

8-4 0 |

|

H.P. MOTOR |

1.5 |

|

Max.Speed R.P.M |

750-85 0 |

|

Price Condition |

5000-20000USD/Set |

|

Packaging |

1Set/Wooden Case |

|

Delivery Lead Time |

7-30days |

|

Minimum Order |

1 set |

|

Guarantee |

1 years |

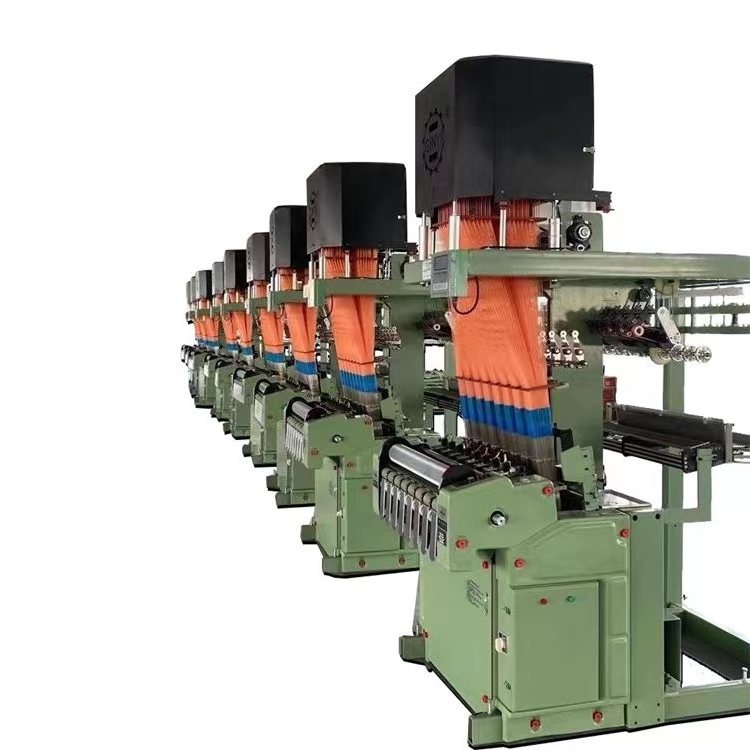

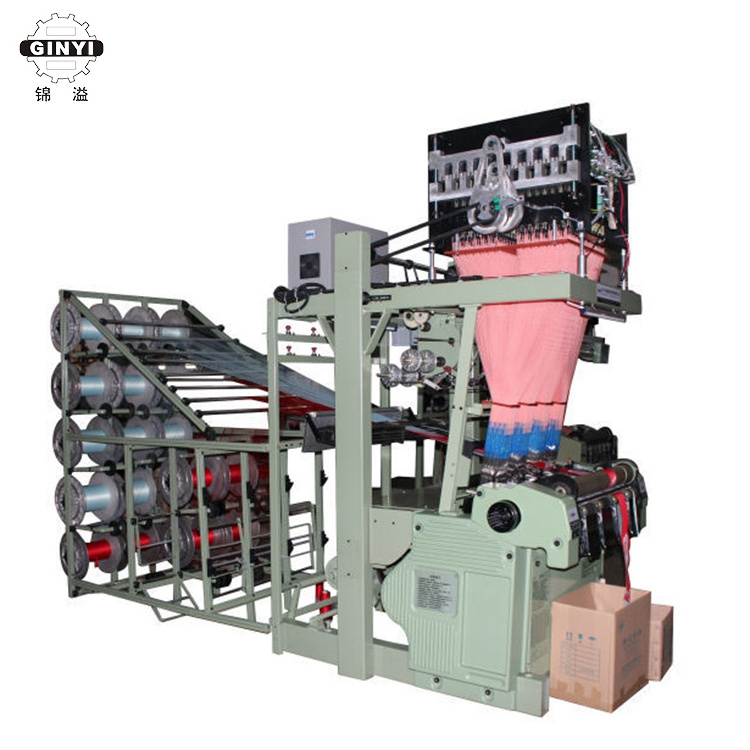

Other size

| Model | GNC-10/30 | GNC-8/45 | GNC-8/30 | GNC-6/55 | GNC-6/45 | GNC-4/65 | GNC-4/80 | GNC-4/110 | GNC-2/160 |

| JACQUARD NEEDLES | 64/128/192/240 | 192/240/384 | 192/240 | 192/240/384/480 | 192/240/384 | 192/240/384/480 | 240/480/640 | 480/640/1120 | 320/384/480 |

| BELT NUMBERS | 10 | 8 | 8 | 6 | 6 | 4 | 4 | 4 | 2 |

| REED WIDTH(mm) | 30 | 45 | 30 | 55 | 45 | 65 | 80 | 110 | 160 |

| HEALD FRAME | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| PICK REPEAT | 8-40 | 8-40 | 8-40 | 8-40 | 8-40 | 8-40 | 8-40 | 8-40 | 8-40 |

| H.P. MOTOR | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| MAX.SPEED R.P.M | 800-900 | 800-900 | 800-900 | 800-900 | 750-850 | 750-850 | 750-850 | 650-800 | 500-650 |

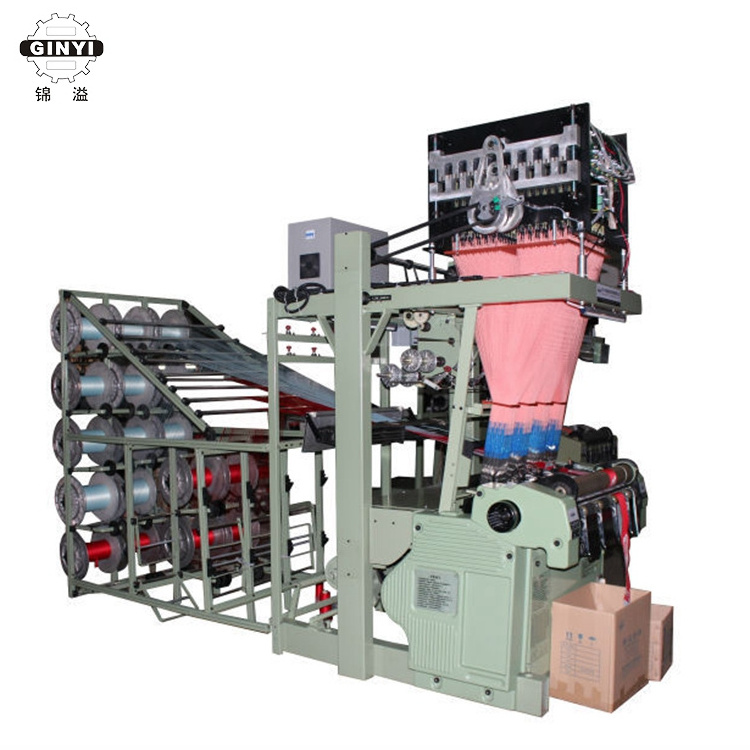

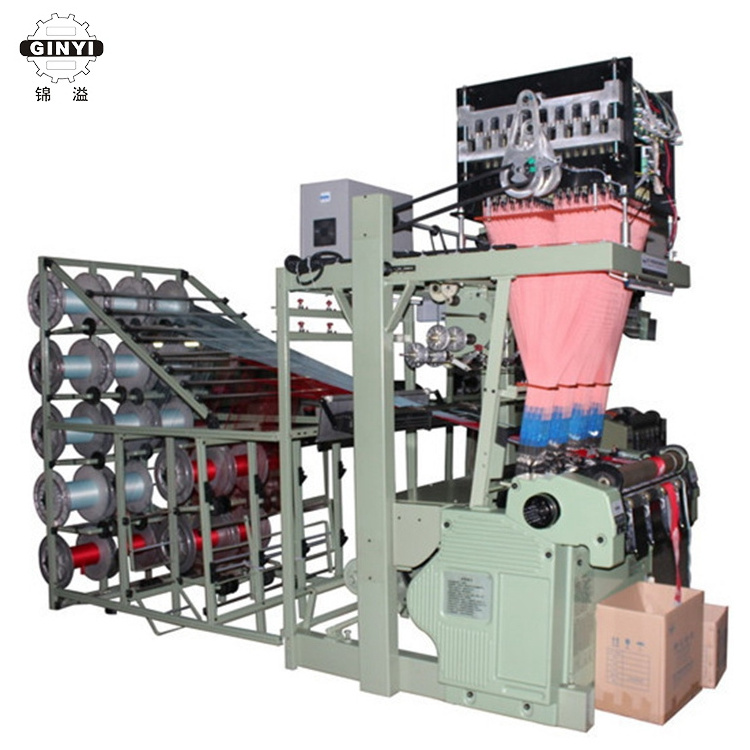

Due to the advanced auto stop devices, reasons of abnormal breakdown can be found out from the situation mentioned above and solved directly. In this case, no operation of the machine is allowed without finding out and solving the problems. There are four stop devices as follow:

1)Warp yarn broken stop device: Needle loom will automatically stop once a dropper fall onto the bar due to the break of the warp yarn.

2)Base yarn broken stop device: Loom will stop when the base spring touching the stop bar due to the break of bas

e yarn while

weaving with base yarn. The base yarn spring and stop bar need to be operated when no base yarn is being used.

3)Weft yarn broken stop device: The machine will automatically stop when weft spring touching the stop pole due to the break of weft yarn.

4)Finished belt involved stop device: One jogging switch is set on the right side of the stop plate to avoid belts being involved into the take-off roller. The operation will be stopped when the switch broke away from the plate.