Q1. Who are we?

A1: We are based in Guangdong, which provides CNC total solutions& cnc lathe machine&milling machine

technical teams and over 10 years of technical and overseas sales experience. sell to Eastern Europe(20.00%), Mid East(20.00%), Southeast Asia(15.00%), Southern Europe(10.00%), South America(8.00%), North America(5.00%), Western Europe(5.00%), Eastern Asia(4.00%), Central America(4.00%), Northern Europe(4.00%), Africa(3.00%), Domestic Market(2.00%).

Q2. How can we guarantee the quality?

A2: Always finishing a pre full testing by our professional engineers;

Always final 100% Inspection before shipment.

Q3. How does your CNC machine work with my production schedule?

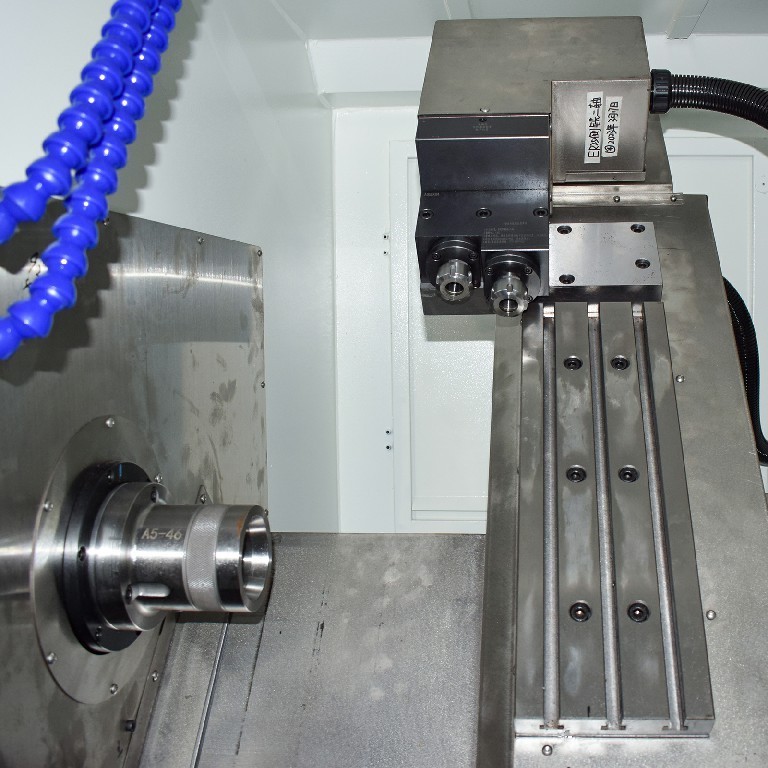

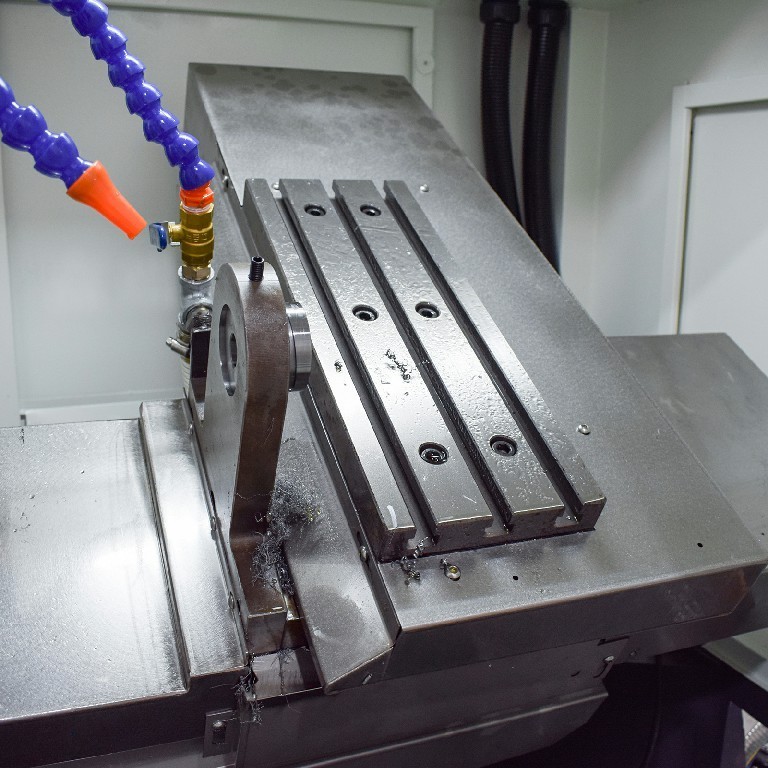

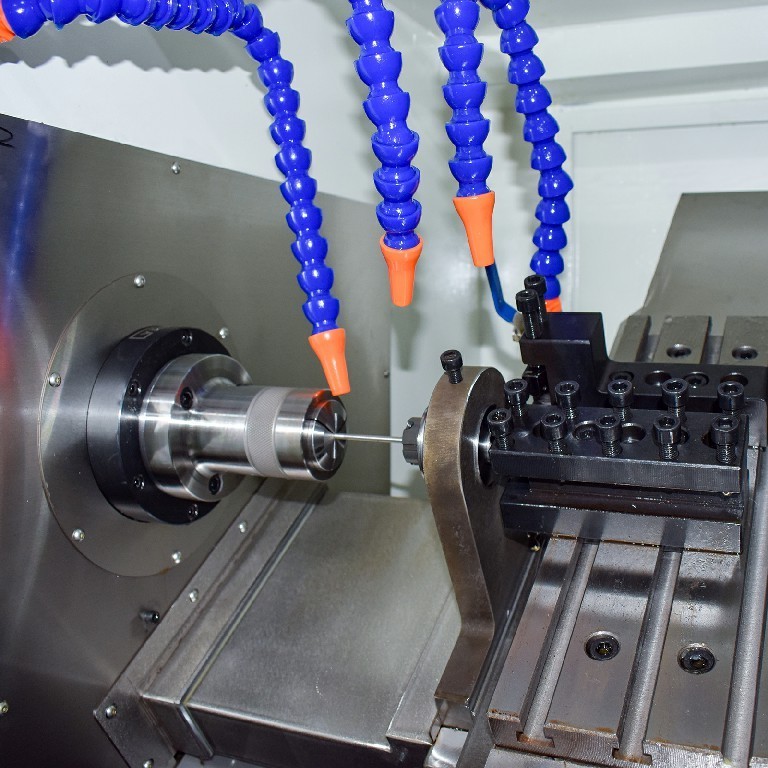

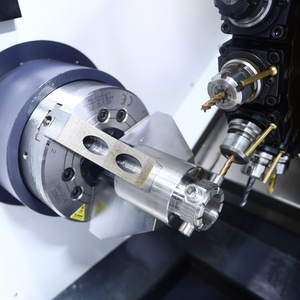

A3: Our machine tools use our complete set of CNC systems, and we can also change the corresponding configuration according to your

needs, such as turrets, kits, etc., to solve the trouble of debugging and refitting after you receive the goods in advance.

Q4. What services can we provide?

A4: 1).Accepted Payment Currency:USD,EUR,CAD,HKD,CNY;

2).Accepted Payment Type:T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash, Escrow;

3).Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean, Italian, and so on.

Q5.What is control mode for feeding Axes?

A5: Our Normal CNC support Pulse+Direction signals for feeding axes drivers; Our Modbus CNC support EtherCAT /Powerlink modbus for feeding axes drivers.

Q6.What is control mode for spindle axes?

A6: There are dual analog voltage outputs(0~10V) for speed control of spindle axis. Our Modbus CNC also support Pulse speed spindle, also can use pulse to control speed of spindle servo system.

Q7.Does your cnc support ATC function?

A7: Yes, our CNC lathe system can support most of turret, like Eletric turret,servo turret,counting turret,etc; We can edit special macro program & plc for special turrets also; And our CNC milling system support Linear type , umbrella type, arm type, turret type tool magazines.

Q8.Does your cnc support booting logo exchange?