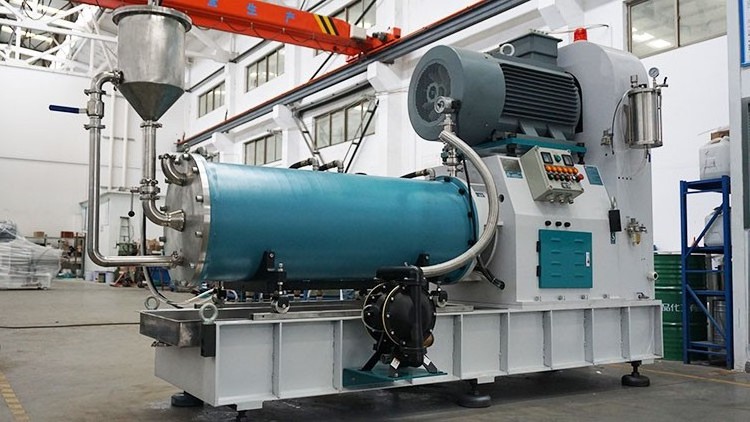

RTSM-100AJ is used in Hunan Magnetci Material Factory. The magnetic material need finish size 1micron to perform a good function in compound material. As horizontal sand mill gots the property of an even finish size distribution, so the final particle size are at D90 smaller than 1micron.

- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

135

-

Range of Spindle Speed(r.p.m):

-

0.1 - 1280 r.p.m

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ROOT

-

Voltage:

-

380V 50Hz 3-phase (can be customized)

-

Dimension(L*W*H):

-

according to different mill model

-

Weight (KG):

-

1500 KG

-

Marketing Type:

-

ROOT Populat Hot Selling Product

-

Machine Name:

-

horizontal 100L bead mill

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

horizontal sand mill/cylindrical grinder for paint/pigment/dye

-

Feeding Pump:

-

Pneumatic diaphragm pump/frequency control gear pump

-

Main Material:

-

ceramic/PU/stainless steel

-

Discharging Mode:

-

dynamic/static

-

Control System:

-

Frequency control/PLC (optional)

-

MOQ:

-

1 Set

-

Certifications:

-

CE / ISO 9001 / ISO 14005

-

Processing Capacity:

-

10-100L

Quick Details

-

Output (kg/h):

-

50 - 1000 kg/h

-

Feeding Size (mm):

-

0.05 - 0.2 mm

-

Output Size (mesh):

-

5000 - 8000 mesh

-

Power (kW):

-

135

-

Range of Spindle Speed(r.p.m):

-

0.1 - 1280 r.p.m

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ROOT

-

Voltage:

-

380V 50Hz 3-phase (can be customized)

-

Dimension(L*W*H):

-

according to different mill model

-

Weight (KG):

-

1500 KG

-

Marketing Type:

-

ROOT Populat Hot Selling Product

-

Machine Name:

-

horizontal 100L bead mill

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

horizontal sand mill/cylindrical grinder for paint/pigment/dye

-

Feeding Pump:

-

Pneumatic diaphragm pump/frequency control gear pump

-

Main Material:

-

ceramic/PU/stainless steel

-

Discharging Mode:

-

dynamic/static

-

Control System:

-

Frequency control/PLC (optional)

-

MOQ:

-

1 Set

-

Certifications:

-

CE / ISO 9001 / ISO 14005

-

Processing Capacity:

-

10-100L

Introduction:

Industrial static disc sand mill is widely applied in the production of water-based and low-viscosity material. RTSM-AJ adopts centrifugal screen discharging with larger flow rate and final product rate. In indistrial production, it could realize different grinding process such as single set recycling grinding, double tank grinding, two sets in series grindingetc. Optimized idsc structure and discharging structe make better finish size and distribution. Finish size could reach 1 micron for D90.

Main Applications:

Now RTSM-AJ series sand mill are widely applied in industries with high requirements for fineness and dispersion property such as disperse dye, vat dye, organic pigment, water slurry, pesticide sc etc.

Core Features:

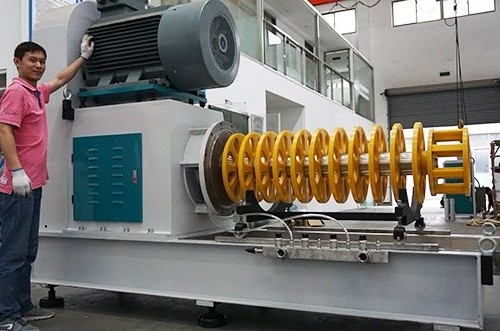

1. Patent grinding disc structure of the grinding bead mill has a bigger action area for the grinding media. Bigger shearing force and higher efficiency.

2. Double cooling systems for the chamber and end cap. The dissolvent which is compatible with grinding material can be added as cooling agency to reduce the production loss because of the leakage.

3. Feeding device: USA imported pneumatic diaphragm pump or frequency control gear pump is optional as clients' requirements. Feeding and discharging tubes are imported USA with good solvent resistant property.

4. High security property. The grinding bead mill will automatically stop working when there is water shortage, air pressure shortage or over-high material temperature.

5. Grinding chamber and rotor is made of high wear resistant alloy steel which has no metallic pollution and discoloring. PU and ceramic material are optional according to actual condition.

6. Reasonable design for inner and outer structure allows stable performance with no vibration and noise.

7. Ceramic and PU material are optional.

8. Frequency control and PLC are optional

9. With CE&ISO9001:2008 qualification.

10. Dynamic or static separating system for different material to ensure smooth discharging.

|

Model

|

Volume

(L)

|

Motor Power

(KW)

|

Medium Size

(mm)

|

Weight

(kg)

|

Dimension

(mm)

|

|

RTSM-10AJ

|

10

|

15

|

0.4-0.6

|

60

|

1200x875x1150

|

|

RTSM-30AJ

|

30

|

30

|

0.4-0.6

|

1000

|

1350x850x1450

|

|

RTSM-60AJ

|

60

|

37

|

0.4-0.6

|

1500

|

2000x900x1800

|

|

RTSM-100AJ

|

100

|

75

|

0.4-0.6

|

1600

|

2300x900x2000

|

|

RTSM-300AJ

|

300

|

135

|

0.4-0.6

|

4500

|

3000x1100x2500

|

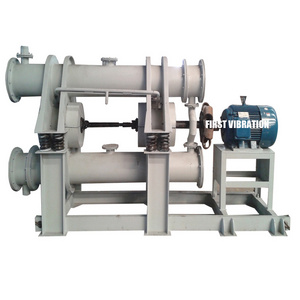

Manufacturing details, smooth maintenance wheels, black zinc supporter

Assembly type double end mechanical seal, for better and safer operation of sand mill

Patent design, centrifugal discharge filter screen, for easy operation and maintenance.

Customer Site-Magnetic Material

Customer Site-Magnetic Material

RTSM-100AJ has adopted assembly type double end mechanical seal, which can undertake higher working pressure to make sure a steady working of the sand mill. There are alarm for low pressure, high pressure, low cooling water, high mechanical seal pressure, low mechanical seal coolant level etc. All the protect system of RT-AJ series will keep the machine and production safe.

Disperse Dye Production Site

RTSM-AJ series is the most suitable machine for pigment (organic pigment, pigment dispersion, pigment paste etc) and dyestuff (disperse dye, vat, acide dye etc). Compared with traditional stir mill or vertical sand mill, horizontal sand mill have many advantages in both easy operation, easy maintenance, high working efficiency, good finish product quality and energy saving etc.

Packing Details : The machine will be covered with anti-abrasion film and then packed in plywood cases.

Delivery Details : 35-60 working days after receiption of down payment.

4. lab mill packed in plywood case

5. Industrial sand mill packing

6. Ship by FCL