- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Certification:

-

CE

-

Voltage:

-

220V/380V/Customized

-

Final product:

-

Copper, Aluminum, Paper, Cobalt Lithium & Graphite Mix Powder

-

Application:

-

All Kinds Of Lithium Batteries

-

Capacity:

-

200-3000kg/h

-

Control:

-

PLC+PC+Touch Screen

-

Feature:

-

Easy Operation; High Seperation Rate

-

Product name:

-

Lithium Battery Recycling Machine

-

Raw material:

-

Scrap Lithium Battery

-

Color:

-

Customer's Requirement

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongyu

-

Weight (KG):

-

8000

-

Marketing Type:

-

New Product 2023

-

Certification:

-

CE

-

Voltage:

-

220V/380V/Customized

-

Final product:

-

Copper, Aluminum, Paper, Cobalt Lithium & Graphite Mix Powder

-

Application:

-

All Kinds Of Lithium Batteries

-

Capacity:

-

200-3000kg/h

-

Control:

-

PLC+PC+Touch Screen

-

Feature:

-

Easy Operation; High Seperation Rate

-

Product name:

-

Lithium Battery Recycling Machine

-

Raw material:

-

Scrap Lithium Battery

-

Color:

-

Customer's Requirement

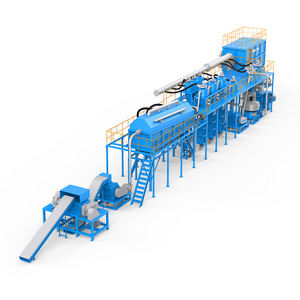

Battery Recycling Machine Lithium Ion Battery Recycling Plant Battery Recycling Machine

Product Description

Scrap Lithium Battery Recycling Plant Scrap Line Equipment , electric vehicle lithium battery and lithium battery anode and cathode plate have certain recycling value significance.Recycling these batteries can not only reduce the environmental pollution caused by waste batteries, but also bring significant social and environmental benefits. Moreover, it can realize the full recycling and utilization of valuable components in waste lithium ion batteries, thus generating huge economic effects.

LITHIUM BATTERY RECYCLING MACHINE APPLICATION

Scrap Lithium battery recycling machine can separate the base metals and graphite powder from the battery by mechanical method. The whole scrap lithium battery recycling plant process is totally dry and eco-friendly.

FEATURES OF LITHIUM BATTERY RECYCLING PLANT

1.Lithium battery recycling plant mainly adopts physical recycling method, which has the characteristics of green and low carbon, energy saving and environmental protection, and no secondary pollution.

2.Taking economic and environmental benefits into account, both valuable components can be utilized and harmful components can be treated innocuously.

3.Lithium battery recycling machine was automatic, high recovery efficiency, strong processing capacity, waste lithium battery valuable components recovery rate of more than 98%.

LITHIUM BATTERY RECYCLING MACHINE STRUCTURE

The pretreatment process of lithium battery recycling machine mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

RAW MATERIALS

The Lithium Ion Battery Recycling Machine is used for dismantling and recycling the soft package battery, cellphone battery, shell battery, cylindrical battery etc. Different types of lithium batteries have different recycling procedures.

TECHNICAL PARAMETERS

|

Model

|

Capacity

|

|

|

ZY-500

|

500 Kg/H

|

|

|

ZY-1000

|

1000 Kg/H

|

|

|

ZY-1500

|

1500 Kg/H

|

|

|

ZY-2000

|

2000 Kg/H

|

|

|

ZY-2500

|

2500 Kg/H

|

|

|

WORKING PERFORMANCE

|

|

|

|

Raw Material

|

Lithium Battery

|

|

|

Final Product

|

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder

|

|

NOTE:

Working voltage:380±10V(415V ,440V also can be custom);

(If you want more detailed parameters and quotations, please contact us)

TECHNICAL STANDARDS

|

Feature Item

|

Indicator Requirments

|

|

Recovery Rate of Metallic Aluminum

|

>98%

|

|

Powder Recovery Rate

|

>98%

|

|

Content of Powder In Metal Aluminum

|

<2%

|

|

Content of Metallic Aluminum In Powder

|

<2%

|

|

Other

|

Contain dust collecter with not pollute

|

|

Qualified Rate

|

99%

|

|

Failure Rate

|

<1%

|

|

CMR

|

≥1.67

|

Details Images

Packing&Shipping

Hot Searches