- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

BEIHAI COMPOSITE

-

Model Number:

-

BH-AFP

-

Material:

-

Aluminum

-

Density:

-

0.2~0.75g/cm

-

Shape:

-

Square

-

Aluminum Thickness:

-

8-200MM

Quick Details

-

Warranty:

-

More than 5 years

-

Size:

-

1200*600, 1200*600

-

Project Solution Capability:

-

NONE

-

Application:

-

Hotel

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

BEIHAI COMPOSITE

-

Model Number:

-

BH-AFP

-

Material:

-

Aluminum

-

Density:

-

0.2~0.75g/cm

-

Shape:

-

Square

-

Aluminum Thickness:

-

8-200MM

Product List

Products Description

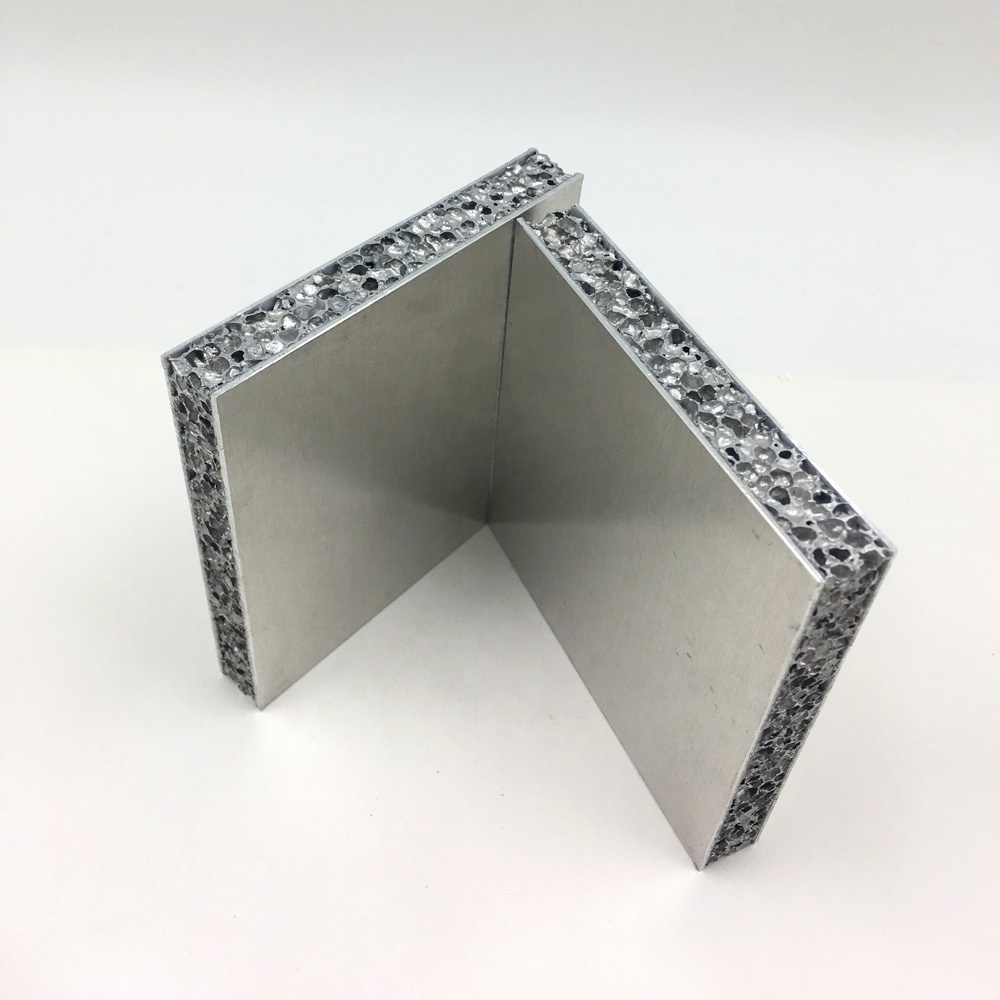

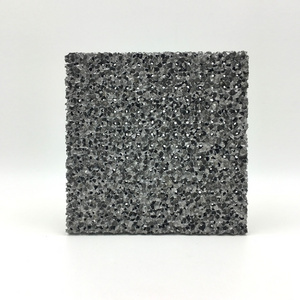

Aluminum Foam Sheet

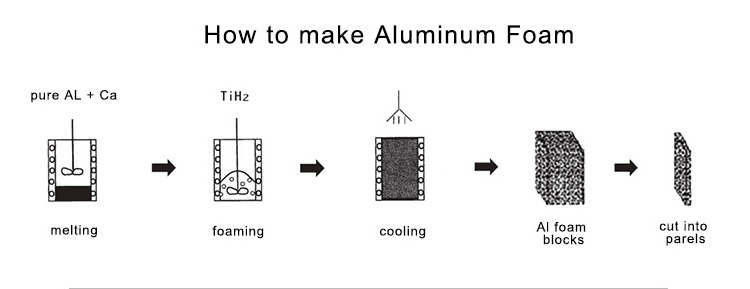

Aluminum foam sheet is a type of aluminum sheet with a porous structure, also known as aluminum foam or aluminum foam material. It is usually made from pure aluminum or aluminum alloy through a mixture of aluminum powder, foaming agent and other additives.

The process of making aluminum foam panels usually includes the following steps: first, aluminum powder is mixed with blowing agents, thickeners and other additives to form the raw material of aluminum foam material. Then, the mixture is injected into a mold and foamed and cured at a certain temperature and pressure to form a solid structure of the aluminum foam material. Finally, the final aluminum foam sheet product is formed through processes such as cutting, trimming and surface treatment.

The process of making aluminum foam panels usually includes the following steps: first, aluminum powder is mixed with blowing agents, thickeners and other additives to form the raw material of aluminum foam material. Then, the mixture is injected into a mold and foamed and cured at a certain temperature and pressure to form a solid structure of the aluminum foam material. Finally, the final aluminum foam sheet product is formed through processes such as cutting, trimming and surface treatment.

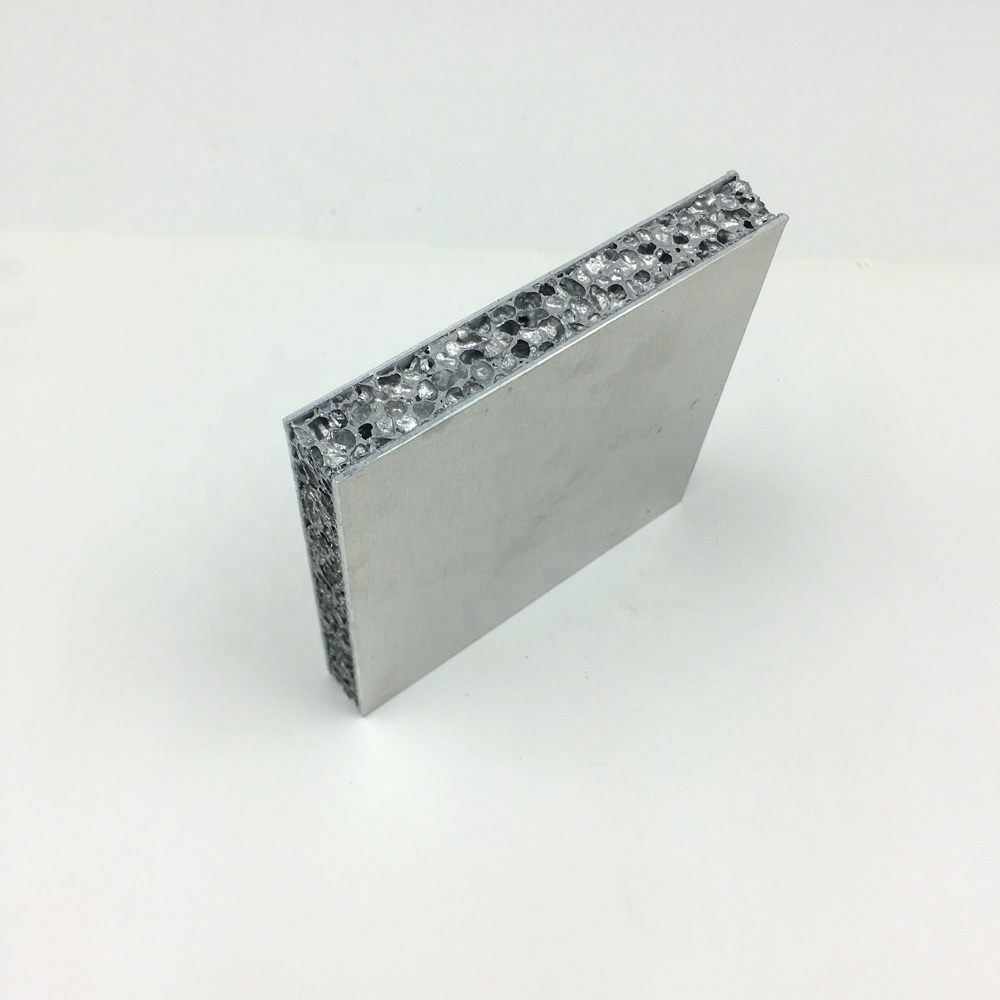

PRODUCT SPECIFICATIONS

|

Performance

|

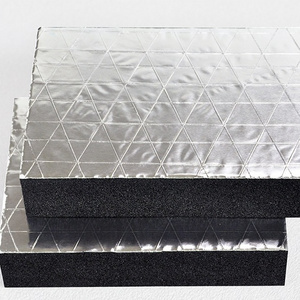

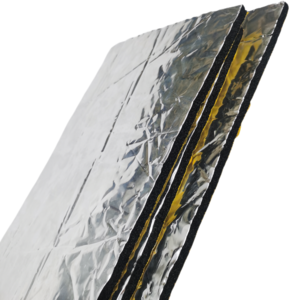

Aluminum Foam with AL-sheet

|

|

Density(g/cm3)

|

<0.6

|

|

Bending Strength

|

16~24

|

|

Soundproof/dB

|

>20

|

|

Shockproof/Magnitude

|

1

|

|

Fire resistance

|

Nonflammable

|

Product Feature

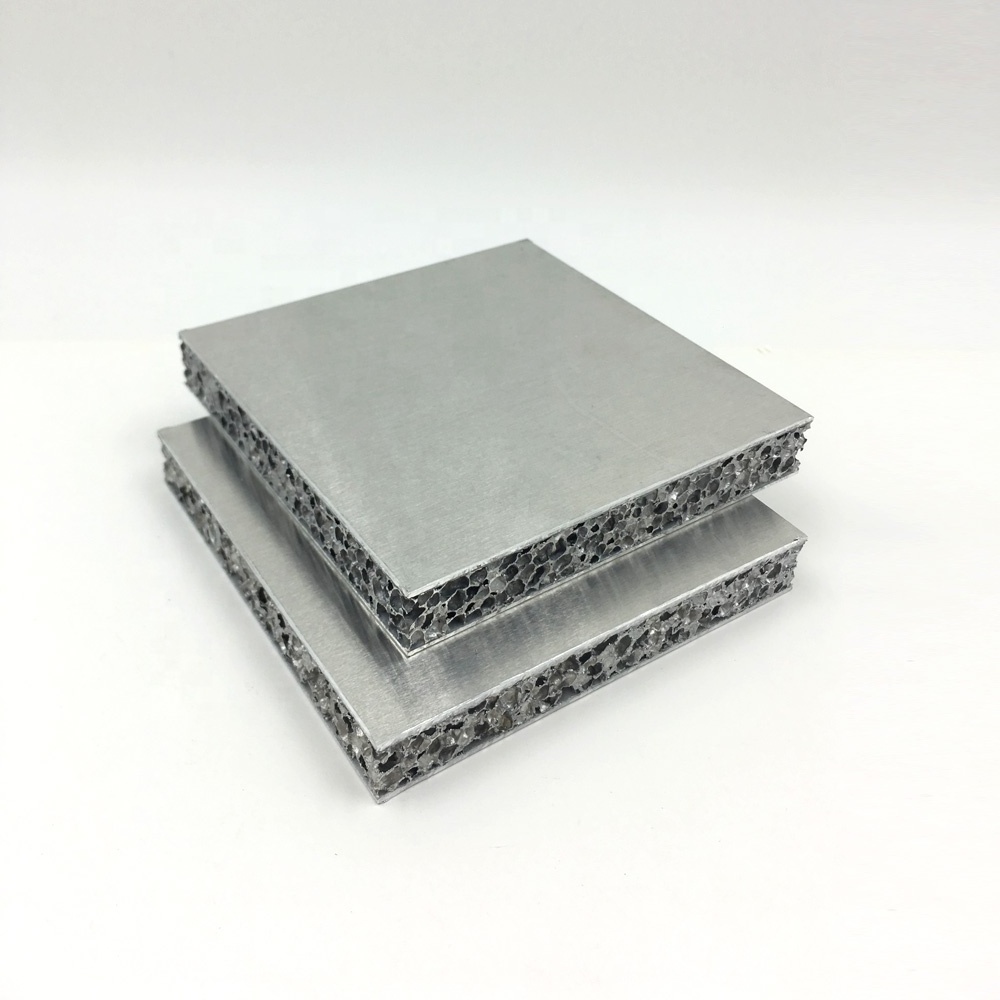

1. Lightweight: Aluminum foam sheet is a lightweight material, much lighter than solid aluminum sheet due to its porous structure and relatively low density. This gives it an advantage in applications where weight reduction is required, such as aerospace and transportation.

2. High Strength: Despite its lower density, the pores in the structure of aluminum foam panels are evenly distributed, creating a strong network structure. This gives aluminum foam panels high strength and rigidity, with some resistance to compression and bending.

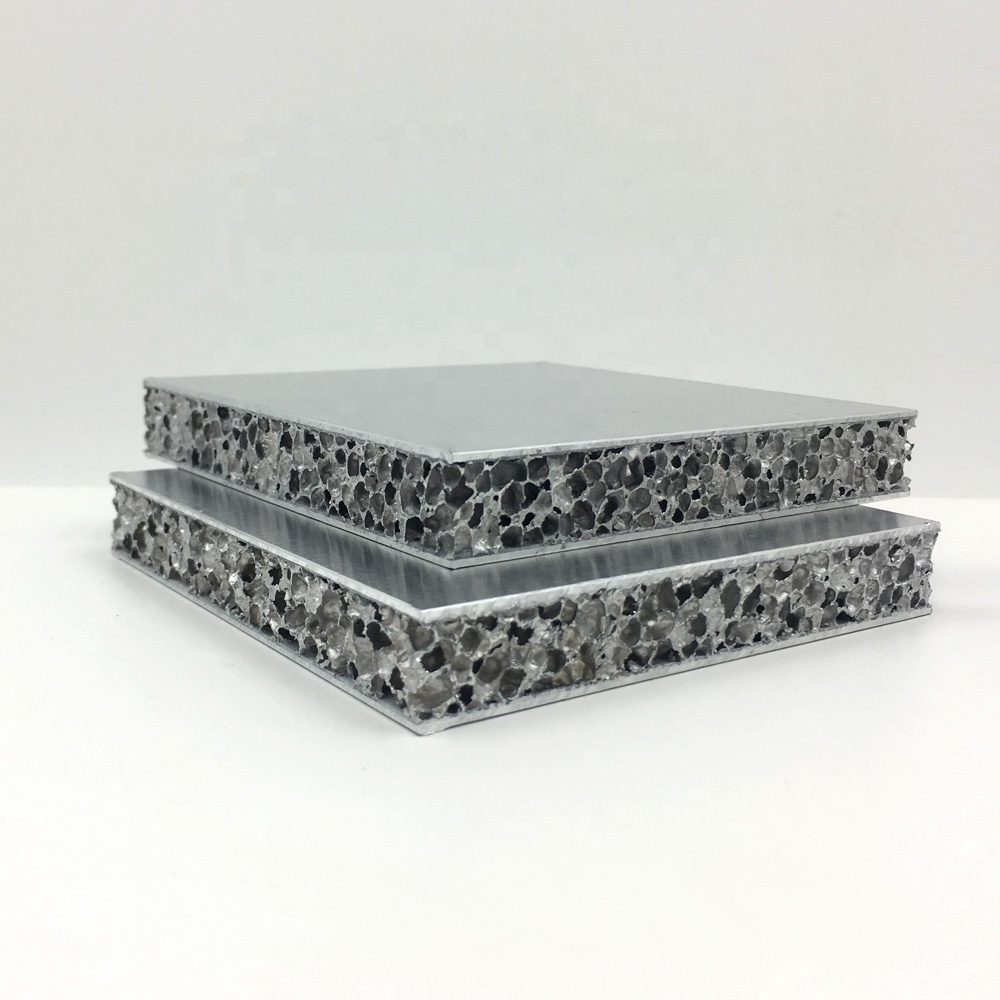

3. Good energy-absorbing properties: Due to the existence of porous structure, aluminum foam panel has excellent energy-absorbing properties. When subjected to impact or extrusion, its pores can absorb and disperse energy, playing the role of buffer and protection, so that it is used in the field of collision protection, military protection and so on.

4. Good thermal and acoustic insulation: the porous structure of aluminum foam panel has good thermal and acoustic insulation properties. It can reduce heat conduction and sound transmission, which is suitable for building insulation, sound control and other applications.

5. Corrosion resistance: Aluminum foam panel is often made of pure aluminum or aluminum alloy with good corrosion resistance, which has excellent corrosion resistance. It can resist oxidation, corrosion and some chemical substances, suitable for some applications in harsh environments.

6. High processability: aluminum foam sheet can be processed by conventional metal processing methods such as cutting, drilling and welding. It can be customized in shape and size according to specific needs, adapting to various application scenarios.

2. High Strength: Despite its lower density, the pores in the structure of aluminum foam panels are evenly distributed, creating a strong network structure. This gives aluminum foam panels high strength and rigidity, with some resistance to compression and bending.

3. Good energy-absorbing properties: Due to the existence of porous structure, aluminum foam panel has excellent energy-absorbing properties. When subjected to impact or extrusion, its pores can absorb and disperse energy, playing the role of buffer and protection, so that it is used in the field of collision protection, military protection and so on.

4. Good thermal and acoustic insulation: the porous structure of aluminum foam panel has good thermal and acoustic insulation properties. It can reduce heat conduction and sound transmission, which is suitable for building insulation, sound control and other applications.

5. Corrosion resistance: Aluminum foam panel is often made of pure aluminum or aluminum alloy with good corrosion resistance, which has excellent corrosion resistance. It can resist oxidation, corrosion and some chemical substances, suitable for some applications in harsh environments.

6. High processability: aluminum foam sheet can be processed by conventional metal processing methods such as cutting, drilling and welding. It can be customized in shape and size according to specific needs, adapting to various application scenarios.

Application

Aluminum foam panels are widely used in aerospace, transportation, construction, electronic and electrical appliances, military protection and other fields due to their light weight, high strength, energy absorption properties as well as good thermal and acoustic insulation and corrosion resistance.

Product packaging

Hot Searches