- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM

-

Product name:

-

custom plastic parts vacuum forming services thermoforming

-

Certification:

-

ISO9001:2008

-

Tolerance:

-

0.2mm-0.5mm

-

Drawing Format:

-

STP, STEP, IGS, X_T

-

Lead time for 1st sample:

-

15 days

-

MOQ:

-

50 pcs

-

Surface finish:

-

Smooth, glossy, paintint etc.

-

Material:

-

ABS, PP, PC, HDPE, PS, etc.

-

Color:

-

Custom Color

-

Application:

-

Industrial

Quick Details

-

Processing Service:

-

Moulding, Cutting, Machining, Customization

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

OEM

-

Product name:

-

custom plastic parts vacuum forming services thermoforming

-

Certification:

-

ISO9001:2008

-

Tolerance:

-

0.2mm-0.5mm

-

Drawing Format:

-

STP, STEP, IGS, X_T

-

Lead time for 1st sample:

-

15 days

-

MOQ:

-

50 pcs

-

Surface finish:

-

Smooth, glossy, paintint etc.

-

Material:

-

ABS, PP, PC, HDPE, PS, etc.

-

Color:

-

Custom Color

-

Application:

-

Industrial

We can customize all kinds of plastic shell, cover, enclosure, housing according to your 3D/CAD files, especially for developing new plastic products. Please feel free to contact if you have suitable

vacuum forming, thermoforming

projects, please also tell us material, quantity, color, surface finish requirement.

Thermoforming customized plastic parts in various fields

Product Description

|

Name

|

Custom vacuum thermoforming parts

|

|

Material

|

ABS, pet, pc, pp, pmma, ps,pvc etc.

|

|

Size

|

Max L4.5m*W2.5m*H1.2m(1~12mm)

|

|

Mould

|

Aluminum mould

|

|

MOQ

|

50 pcs, sample order is acceptable.

|

|

Finish

|

Smooth, glossy, painting etc.

|

|

Shipping

|

Delivery by sea, air or train.

|

|

Uasge

|

R&D of new plastic products.

|

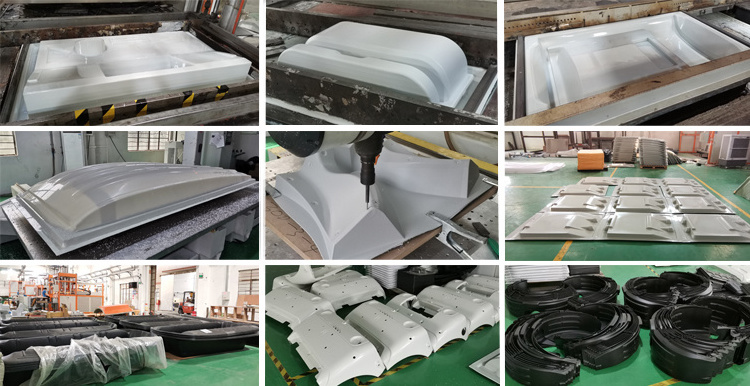

Details Images

Process Interpretation

❀ What is thermoforming and vacuum forming?

Thermoforming is a process in which plastics are placed in a high heat environment and heated to a softening state, and then it can be manipulated into other shape. Vacuum forming uses vacuum to make heated and softened plastic sheets close to the surface of the mold and form

.

❀ What are the benefits of vacuum forming?

Vacuum forming is an efficient and cost effective way to achieve mass production.

(1)The upfront cost are usually much more cheaper;

(2)The lead times from tooling to production is generally much shorter than other process such as injection molding;

(3) It is extremely suitable for product market acceptance test, low cost and small batch production.

Quality Assurance

Professional technical support of the design and production can be provided to you, and all the products will be checked by our Quality Control team.

As for your projects, our highly skilled team will be with you every step of the way, from sample preparation to mass production. Our team will be working closely with you to assist in choosing the appropriate materials and production method, and ensure the quality and timely delivery of the product.

As for your projects, our highly skilled team will be with you every step of the way, from sample preparation to mass production. Our team will be working closely with you to assist in choosing the appropriate materials and production method, and ensure the quality and timely delivery of the product.

Verified experienced supplier on Alibaba by Intertek

We are vacuum forming products manufacturer which is verified by ISO and intertek. With more than 13 years of experience on vacuum forming products, we have bulit friendly and steady cooperation with many customers from all over the world. We have full confidence to be your reliable thermoforming partner in the future.

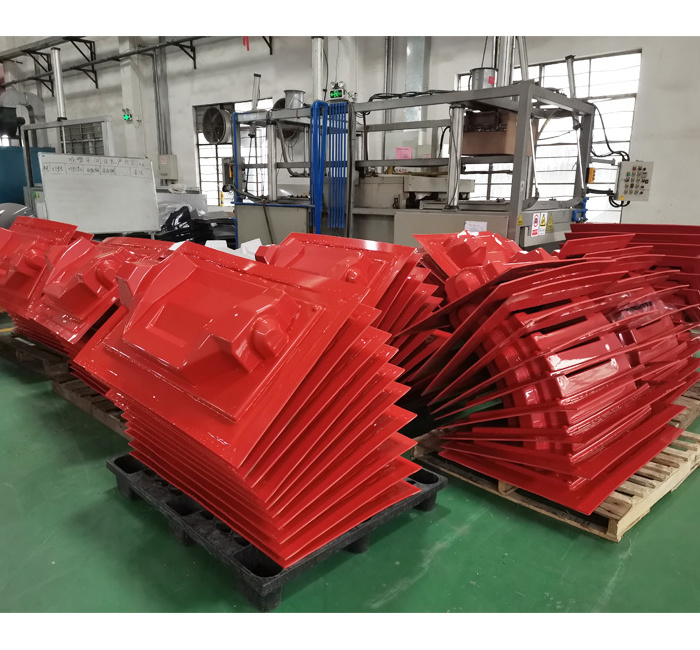

Vacuum forming factory images

of large enterprise for the enviroment and organization. In this enviroment, we can produce products that meet international

quality standard!

precision and can guarantee the tolerance of the vacuum formed pieces.

done in a short time. Maximum size: L4.5m*W2.5m*H1.2m

The largest part we made is 3.5m*1.3m.

We're especially experienced in large parts vacuum forming manufacturing.

1. Large parts can be easily processed;

2. Imported from Germany with high precision which guarantee the parts tolerance;

3. More efficient with more machines;

4. Lower cost because of hign efficient.

2. Imported from Germany with high precision which guarantee the parts tolerance;

3. More efficient with more machines;

4. Lower cost because of hign efficient.

also for manufacturing of fixture, which is auxiliary tool to ensure product precision of sizes.

This is just a glance of our post-processing room, there are 3 post processing rooms in our factory. We have following surface

finish for plastic parts, for your reference.

1. Tech polish; 2. Mirror polish; 3. Painting;

4. Color pigment; 5. Grey primer; 6.Metalizing

7. Chrome plating; 8. Silk screen printing;

9. Laser etching.

finish for plastic parts, for your reference.

1. Tech polish; 2. Mirror polish; 3. Painting;

4. Color pigment; 5. Grey primer; 6.Metalizing

7. Chrome plating; 8. Silk screen printing;

9. Laser etching.

Hot Searches