- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Processing Line

-

Voltage:

-

220V/380V

-

Power:

-

100-1500KW

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

Capacity

-

Year:

-

2023

-

Product name:

-

Tomato prossecing machine

-

Evaporation type:

-

Forced circulation evaporator

-

Material:

-

SUS304/sus316L

-

Automation:

-

Automatic control/semi auto

-

Usage:

-

Industrial Usage

-

Color:

-

Sliver

-

Function:

-

Multifunctional

-

Feature:

-

High Efficiency Easy Operate

-

Advantage:

-

Drying High Efficiently

-

Package:

-

Wooden Case

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BEYOND

-

Type:

-

Processing Line

-

Voltage:

-

220V/380V

-

Power:

-

100-1500KW

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

Capacity

-

Year:

-

2023

-

Product name:

-

Tomato prossecing machine

-

Evaporation type:

-

Forced circulation evaporator

-

Material:

-

SUS304/sus316L

-

Automation:

-

Automatic control/semi auto

-

Usage:

-

Industrial Usage

-

Color:

-

Sliver

-

Function:

-

Multifunctional

-

Feature:

-

High Efficiency Easy Operate

-

Advantage:

-

Drying High Efficiently

-

Package:

-

Wooden Case

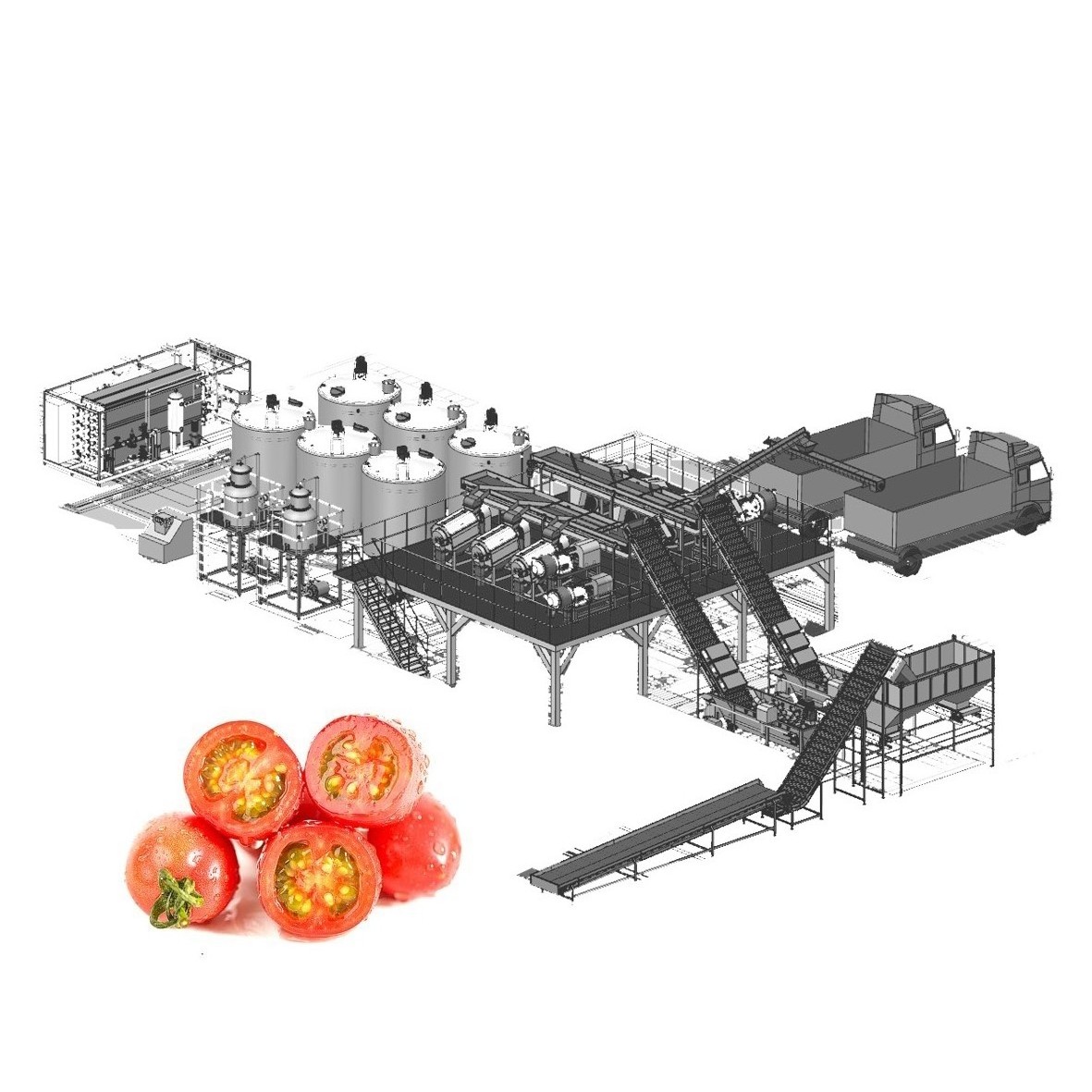

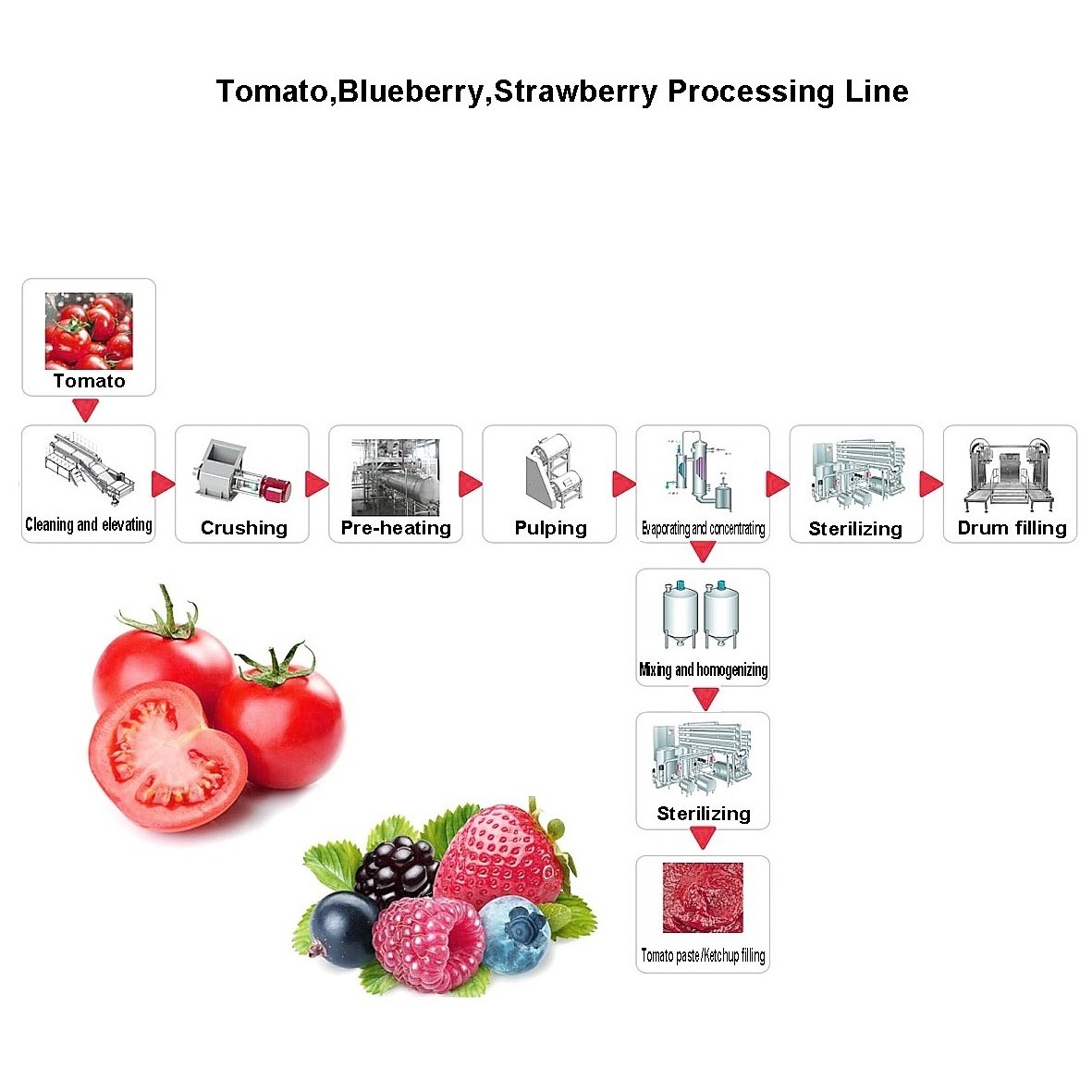

Tomato factory machines tomato prossecing machine tomato puree making machine

A tomato processing machine is a piece of equipment used to automate and streamline the process of turning fresh tomatoes into various tomato-based products, such as tomato sauce, tomato paste, tomato juice, or diced tomatoes. These machines are commonly used in commercial food processing facilities and can handle large volumes of tomatoes efficiently.

Here are some potential advantages of using a tomato processing machine:

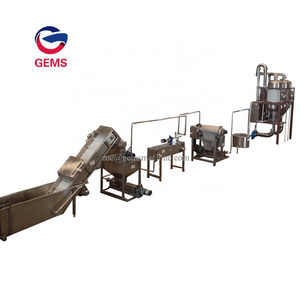

Increased Efficiency: Tomato processing machines are designed to handle a high volume of tomatoes quickly and efficiently. They can peel, chop, crush, or puree tomatoes at a much faster rate than manual processing, saving time and labor.

Consistency in Product Quality: By using a tomato processing machine, the results are more consistent compared to manual processing. The machine ensures that tomatoes are processed uniformly, leading to consistent texture, taste, and quality in the final product.

Waste Reduction: Tomato processing machines are designed to extract maximum juice and pulp from the tomatoes, minimizing waste. This can result in cost savings for the manufacturer and also reduce environmental impact.

Increased Shelf Life: Tomato processing machines often include features like pasteurization or sterilization, which help extend the shelf life of the tomato products. This allows manufacturers to store and distribute the processed tomatoes for longer periods without compromising product quality.

Versatility: Tomato processing machines can be versatile, capable of processing various types of tomatoes and producing different tomato-based products. They can handle different sizes, ripeness, and varieties of tomatoes, giving the manufacturer flexibility in their product offerings.

Hygiene and Safety: Tomato processing machines are typically made from stainless steel, which is easy to clean and maintain, ensuring hygiene and food safety standards are met. They also come with safety features to prevent accidents and ensure worker safety.

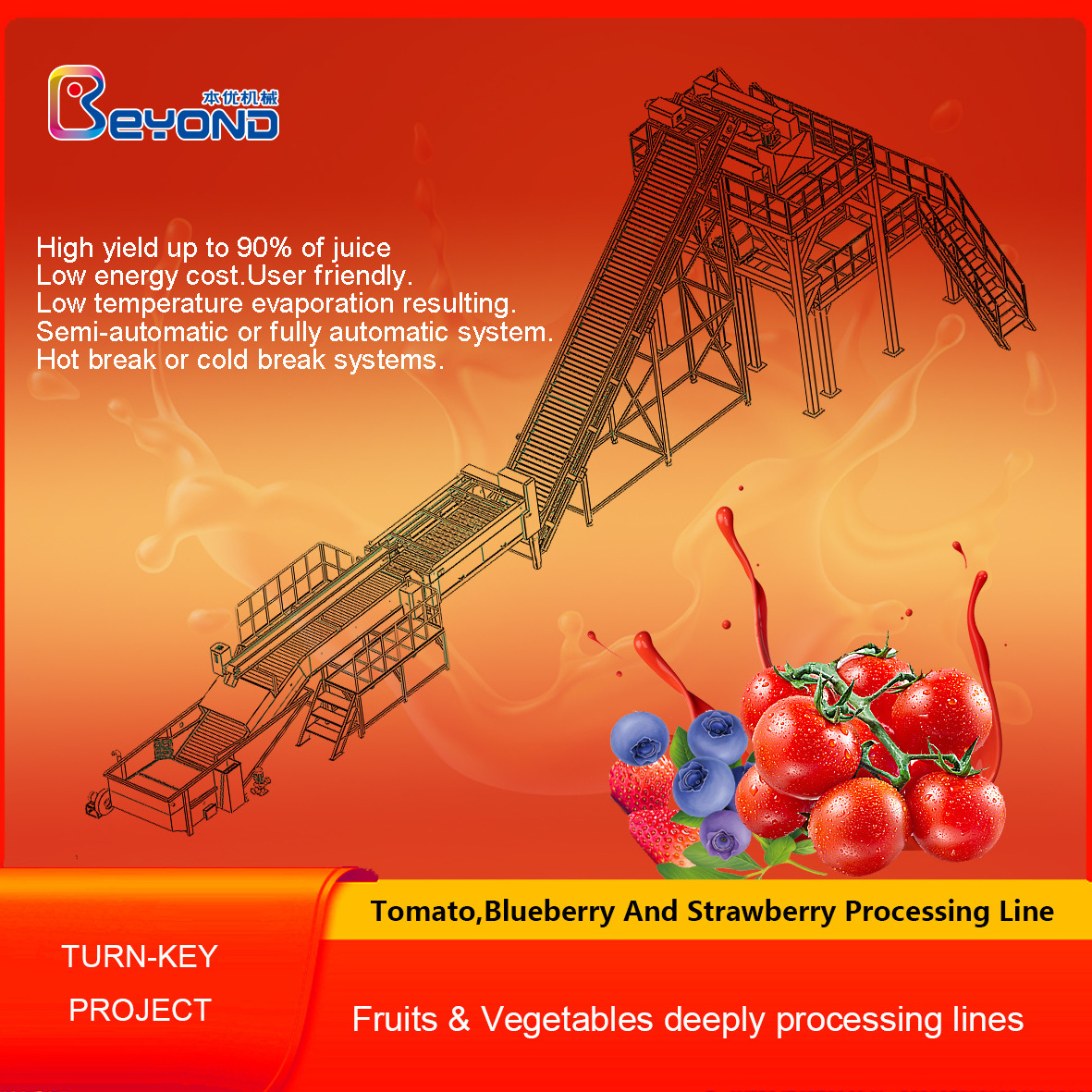

Shanghai beyond offers complete set of tomato ketchup line or sauce processing machinery on turnkey basis to produce the following end products from tomatoes.

- Tomato Puree from tomato processing line

- Tomato Paste from tomato paste production line

- Tomato Ketchup/Sauces from tomato ketchup puree plant

- Tomato Juices from tomato juice processing plant

Packing lines can be offered depending upon the requirement like Product in glass bottles, Cans, Drums, etc. Manufacturing process involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators. Evaporation plants are versatile in nature and can concentrate other juices also.

SALIENT FEATURES :

- High yield up to 90% of juice

- Low energy cost.

- Low temperature evaporation resulting improved quality of products.

- User friendly.

- Semi-automatic as well as fully automatic system available.

- Both hot break and cold break systems available.

Project Photos Show:

Pre sales services

Post sales services

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.