- Product Details

- {{item.text}}

Quick Details

-

Reverse Speed(km/h):

-

24

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

sam

-

Dimension(L*W*H):

-

8,703*2,630*3,360

-

Product name:

-

mini motor grader SAM919 SAM Grader

-

Certification:

-

iso

Quick Details

-

Forward Speed(km/h):

-

39

-

Engine Brand:

-

imported brand

-

Working diameter:

-

_

-

Reverse Speed(km/h):

-

24

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

sam

-

Dimension(L*W*H):

-

8,703*2,630*3,360

-

Product name:

-

mini motor grader SAM919 SAM Grader

-

Certification:

-

iso

mini motor grader 919 Grader

Product Description

Tandem Axle

- Leveraging designing and experience on MG tandem axle

- Improved bearing layout and optimized load distribution with 4 planetary gears final drive

- Less down time and reduced labor and service cost for maintenance and repairing

- Longer service interval for lubrication oil change

-

Leading in class manufacturing and quality control level, mandatory performance testing before delivering to MG asbly line

Control System

- 7 position link bar with electric over hydraulic control allows ease of operation from within the cab

- Optimum blade reach capability, quick DCM re-positioning for greater reach for better working on high bank side slope

- The link bar is essential for extending reach capability when cutting a bank slope or back slope of a ditch

-

Replaceable bushings reduce service time and cost

Blade Float

- Standard blade float function allows blade to lower without hydraulic pressure for increased versatility

- Blade float is engaged by pushing the left and right lift cylinder controls all the way forward past the detent

-

Provides protection for machine and pavement during snow removal and snow plowing

Hydraulic System

- Proportional Priority Pressure Compensating (PPPC) Valves contain specifically cut spools for motor grader applications, continuously matching of hydraulic flow and pressure to power demands, allowing ease of multi-function control for optimizing working efficiency

- World-class variable displacement piston pump, efficiently reduces power consumption and hydraulic system heat, improving fuel efficiency

- Load-sensing hydraulic system provides consistent and precise blade movement, improving finishing performance

-

Inboard lock check valves within PPPC, prevents inadvertent cylinder movement and potential leaks

Drawbar

- A-frame tubular design drawbar provides maximum strength and durability

- Replaceable drawbar draft ball (bolted – not welded) for less service time and cost

-

Easy removal of wear shims to adjust drawbar

Front Frame

- Flanged box section design removes welds from high stress areas, improving reliability and durability

- Continuous top and bottom plate construction provides consistency and strength, improving front frame durability

- Hydraulic hose routing minimizes exposure to damage and provides quick access for service

-

Maintenance-free bushings improve durability and reduce overall service cost

Control Layout

- Short throw levers are efficiently spaced, allowing ease of multi-function control

-

Short lever travel (40mm) with low lever effort reduces operator fatigue

Large Cab

- High performance dashboard with 3 levels alarming monition system

- Cab mounted on the front frame provides exceptional view to blade and front axle even during articulation

- Large cab with 1.9m height and 30% larger space,provides exceptional comfort

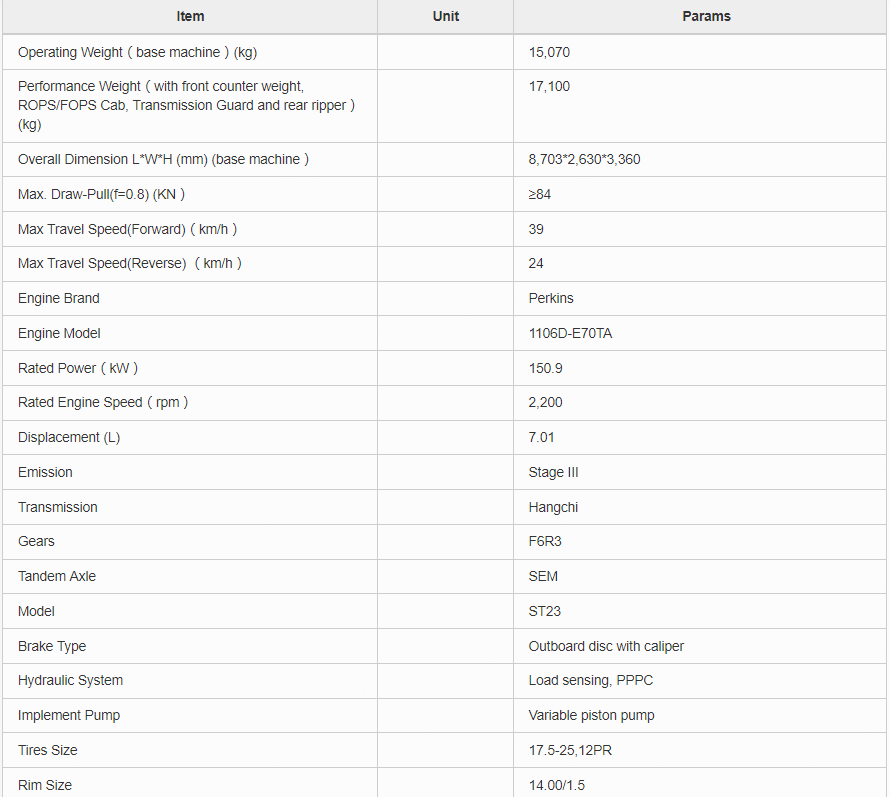

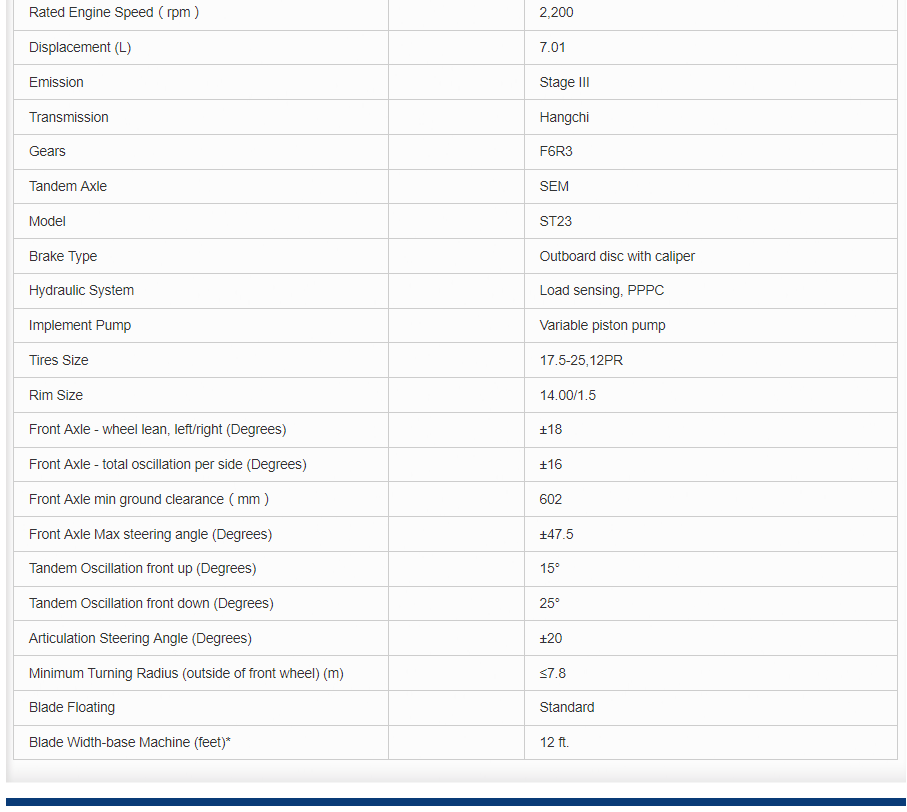

Performance Paramete

Pictures

Packaging & Shipping

Hot Searches