- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/110V

-

Dimension(L*W*H):

-

68.5*47.5*59CM

-

Warranty:

-

12 Months

-

Certification:

-

CE,SGS

-

Weight:

-

40KG

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

wanxin, WANXIN

-

Model Number:

-

WX-101V, WX-101V

-

Voltage:

-

220V/110V

-

Dimension(L*W*H):

-

68.5*47.5*59CM

-

Warranty:

-

12 Months

-

Certification:

-

CE,SGS

-

Weight:

-

40KG

Wanxin Aluminum Epoxy Powder Coating Machine

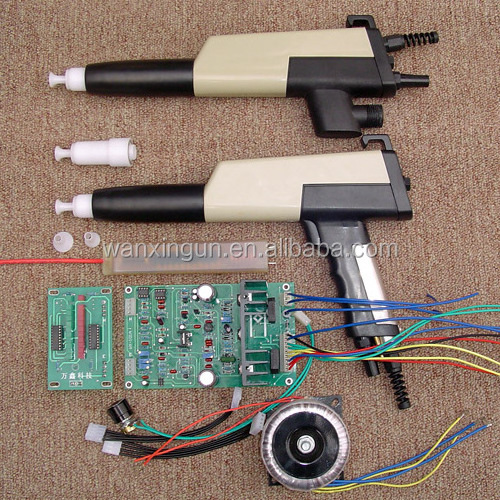

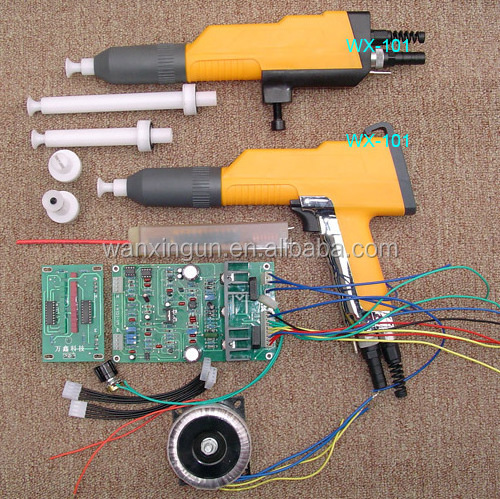

1. Configuration:

Manual gun *1 + host*1 + powder pump*1+trolley*+motor*1+oil-water separator*1 + air pressure regulating valve*1

2. Technical parameter

A). Host:

Input power voltage: 90-260v 50-60Hz

Input power: 40w

B). Powder supply &air soure

Electromagnetic valve control power voltage: 24v DC

Input air pressure: 0-0.6Mpa

Output air pressure: 0-0.5Mpa

Max. Air consumption: 13.2m/h(0.4Mpa)

C). Powder gun

Wx-101A grey electrostatic powder gun

Input air pressure: <=0.3Mpa

Output powder volume: Max. 550g/min

Output power voltage: 0- -100kv

Output current: 0-150uA

Gun weight: 480g

Brief Introduction:

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermoset polymer . It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals , such as "whiteware," aluminium extrusions , and automobile and bicycle parts. Newer technologies allow other materials, such as MDF ( medium-density fibreboard ), to be powder coated using different methods.

The powder coating process involves three basic steps:

- Part preparation or the pre-treatment

- The powder application

- Curing

- The process of the powder coating is like this: The powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns. The guns spray a powder/air mixture onto the workpieces