- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

60M*4.5M*6M

-

Weight:

-

45000 KG

-

Product name:

-

High speed BOPP transparent tape coating machine

-

Base Material:

-

BOPP film OPP Film

-

Coating width:

-

500~1600mm

-

Coating speed:

-

50~300M/min

-

Glue type:

-

water base Acrylic

-

Coating thickness:

-

0.02~0.05mm

-

Coating method:

-

mayer-bar

-

Dry system:

-

Steam

-

Temperature control:

-

Max 120

-

After Warranty Service:

-

Video technical support

Quick Details

-

Voltage:

-

380V, 50HZ,3P (by customer)

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BOPP TRANSPARENT TAPE COATING MACHINE

-

Dimension(L*W*H):

-

60M*4.5M*6M

-

Weight:

-

45000 KG

-

Product name:

-

High speed BOPP transparent tape coating machine

-

Base Material:

-

BOPP film OPP Film

-

Coating width:

-

500~1600mm

-

Coating speed:

-

50~300M/min

-

Glue type:

-

water base Acrylic

-

Coating thickness:

-

0.02~0.05mm

-

Coating method:

-

mayer-bar

-

Dry system:

-

Steam

-

Temperature control:

-

Max 120

-

After Warranty Service:

-

Video technical support

Products Description

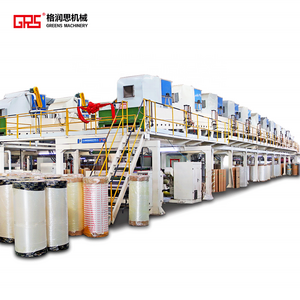

BOPP Adhesive Tape Coating Machine

BOPP Adhesive Tape Coating Machine

This Machine used to produce BOPP adhesive tape jumbo rolls.The main structures are unwinder , coater, drying ovens, cooling roller unit, rewinder, frame, duct, electrical system

Function introduction

1. Unwinder: Release the BOPP blank film, automatic pick up new roll of blank film.

2. Coater: coat glue on the blank film, coating method use mayer bar coater or comma roller coater.

3. Drying ovens: Drying the materials, hot air system, the heat source is provided by the user. Steam boiler, Hot blast stove,

Heat transfer oil boiler, electric one of them. The length of the oven is determined by the maximum capacity required by the user.

4. Cooling roller unit: The raw material after high temperature drying can be cooled rapidly.

5. Rewinder: rewinding the material into a roll, got the BOPP adhesive tape jumbo roll.

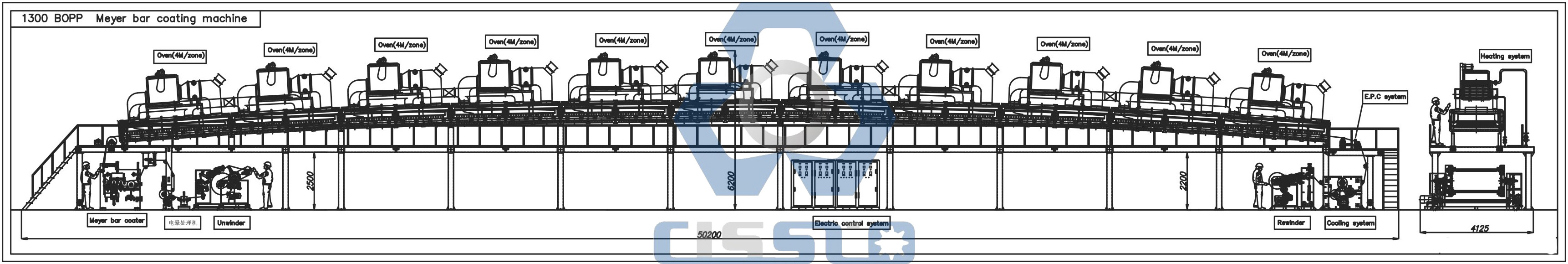

6. Machine Drawing for reference , it can be customized as the requirements.

2. Coater: coat glue on the blank film, coating method use mayer bar coater or comma roller coater.

3. Drying ovens: Drying the materials, hot air system, the heat source is provided by the user. Steam boiler, Hot blast stove,

Heat transfer oil boiler, electric one of them. The length of the oven is determined by the maximum capacity required by the user.

4. Cooling roller unit: The raw material after high temperature drying can be cooled rapidly.

5. Rewinder: rewinding the material into a roll, got the BOPP adhesive tape jumbo roll.

6. Machine Drawing for reference , it can be customized as the requirements.

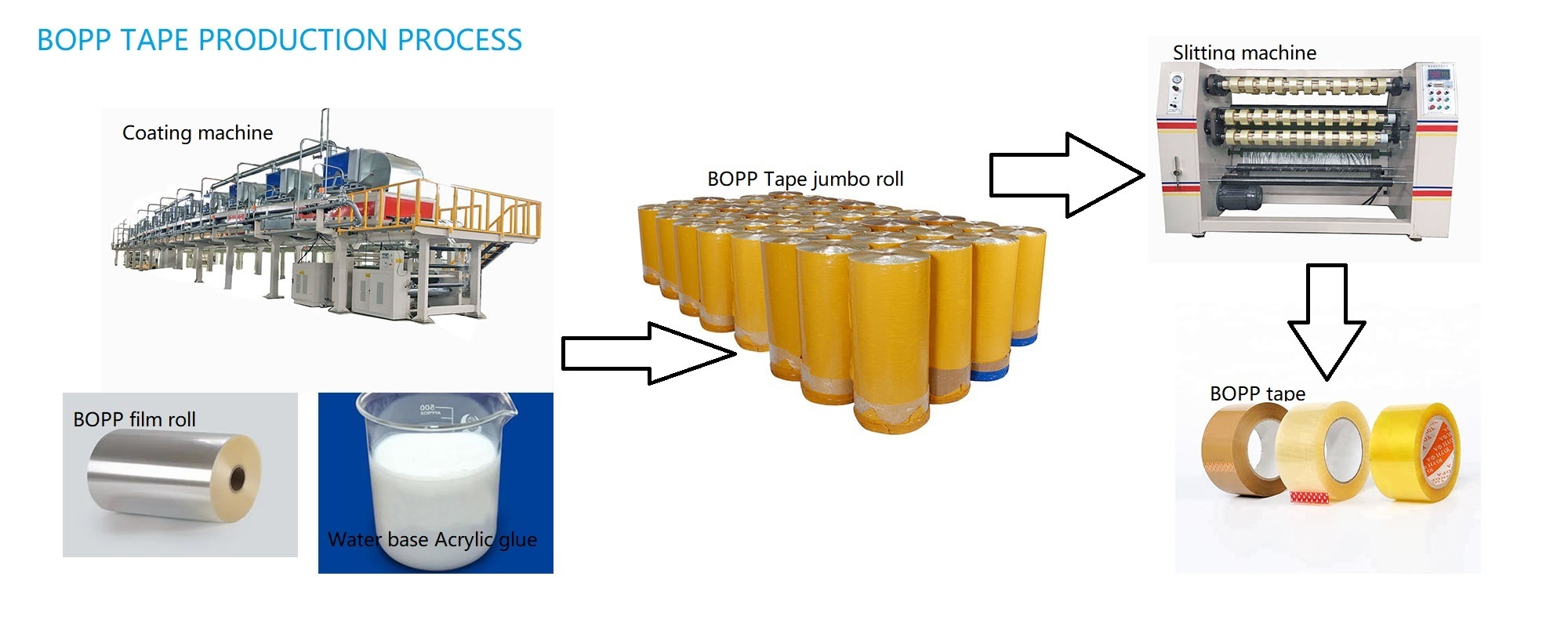

BOPP Adhesive Tape production process

1.Coating adhesive

2.Slitting

3.Packing

3.Packing

Raw materials for BOPP adhesive tape production line

BOPP Film roll

Width:500~1620mm

Film thickness:23~37mic

Film Roll diameter: max.700mm

Film Length per roll:4000~8000Meters

Film thickness:23~37mic

Film Roll diameter: max.700mm

Film Length per roll:4000~8000Meters

Water base acrylic adhesive

Solid content:50~55%

Viscosity:100~300cps

Viscosity:100~300cps

Paper core

Internal diameter:76mm

Length of paper core:500~1600mm

Thickness of paper core: 5~10mm

Thickness of paper core: 5~10mm

Production Specification

Technical parameter

|

|

Model 500

|

Model 800

|

Model 1000

|

Model 1300

|

Model 1600

|

|

Working width:

|

Max.500mm

|

Max.800mm

|

Max.1000mm

|

Max.1300mm

|

Max.1600mm

|

|

Production speed: (Customized)

|

40~100M/min

|

60~150M/min

|

60~150M/min

|

100~300M/min

|

100~300M/min

|

|

Production capacity: 8 hours

|

0.5~1ton

|

1~3tons

|

1.5~4tons

|

2.5~6tons

|

3~8tons

|

|

Heat consumption per hour:

|

Max.300000 kcal

|

Max.600000 kcal

|

Max.600000 kcal

|

Max.1200000 kcal

|

Max.1200000 kcal

|

|

Worker :

|

2~3 workers

|

2~3 workers

|

2~3 workers

|

2~3 workers

|

2~3 workers

|

Product Images

Details images

Unwinder

2-shafts automatic exchange

Auto joint non-stop

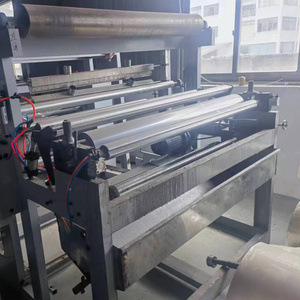

Coater

Mayer-bar coating or Comma roller coating way

Drying oven

Hot air drying

Heating source:electric, steam

boiler

, c

onduction oil

boiler

, hot blast stove

Cooling & Rewinder

Cooling roller & 2-shafts automatic rewinding

Cold water circulation

Auto joint non-stop and auto cutting

Machining &

Assembling show

Frame

Steel plate processing

Frame, machine skeleton

Oven skeleton and inner

Operation interface

Blower and exhaust fan for drying system

Electrical control system

Drying oven

Assembling Unwider, rewinder

Assembling Coater, cooling system

Packaging and delivery

Standard ocean packages

FAQ

1. What products do you need to produce?

BOPP tape, PVC insulation tape, PE/PET protective film, PET/PI electrical tape, Masking tape, double-side tape, Label self

adhesive , Sublimation paper, non-woven/cloth medical adhesive tape.

2. What is parameter of base materials?

Thickness:

Width of base material roll:

Diameter of base material roll:

Weight of material:

3. What kind of adhesive to apply for the products?

Acrylic, rubber or hot melt

4. What is the type of adhesive?

Water base , solvent base, or solvent-less

5. What is parameter of adhesive?

Solid content:

Viscosity:

6. What is production capacity for the machine that you want? Customizable

Low speed:40~80M/min

Medium speed: 100~150M/min

High speed: 200~300M/min

7. How long is the delivery time?90~120days

8.Installation and debugging services?

We can send engineers abroad for installation guidance and operation training.

9.Warranty period and after sales services.

The equipment is guaranteed for one year, Outside the warranty period, we provide paid maintenance services.

BOPP tape, PVC insulation tape, PE/PET protective film, PET/PI electrical tape, Masking tape, double-side tape, Label self

adhesive , Sublimation paper, non-woven/cloth medical adhesive tape.

2. What is parameter of base materials?

Thickness:

Width of base material roll:

Diameter of base material roll:

Weight of material:

3. What kind of adhesive to apply for the products?

Acrylic, rubber or hot melt

4. What is the type of adhesive?

Water base , solvent base, or solvent-less

5. What is parameter of adhesive?

Solid content:

Viscosity:

6. What is production capacity for the machine that you want? Customizable

Low speed:40~80M/min

Medium speed: 100~150M/min

High speed: 200~300M/min

7. How long is the delivery time?90~120days

8.Installation and debugging services?

We can send engineers abroad for installation guidance and operation training.

9.Warranty period and after sales services.

The equipment is guaranteed for one year, Outside the warranty period, we provide paid maintenance services.

Contact Me

Contact person:Ms. Shelly He

Cell phone/Whatsapp:+86 13391085881 Wechat: Cissco_machinery

Tel:+86 2138726828 Fax.+86 2138726369

Tel:+86 2138726828 Fax.+86 2138726369

CISSCO Machinery Co.,ltd

Add:9F, NO.58#, New Jinqiao Road, Shanghai Zip:201206

Website: http://www.wecoater.com

Related Products

Company Introduction

Introduction

has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded

by large companies in more than 30 countries.

Main products:

Adhesive tape coating machine series:

1. BOPP, PVC,PET/PI adhesive tape coating machine

2. PE, PET protective film , release film coating machine

3. PET explosion proof film, thermal insulation film, reflective film optical precision coating machine

4. Thermal sublimation transfer paper, photo paper, PP paper, advertising consumables coating machine

5. Label, double side, masking, foam, car sticker, wallpaper, self adhesive tape coating and laminating machine

Adhesive tape or film roll deep processing equipment

1. Slitting and rewinding machine

2. Cutting machine

3. Laminating and Inspection machine

4. Packing machine

Other customized equipment

1. Small type laboratory multi-function coating machine

2. Medical adhesive tape production and R & D coating machine

Advantages :

1. 20 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services;

1. BOPP, PVC,PET/PI adhesive tape coating machine

2. PE, PET protective film , release film coating machine

3. PET explosion proof film, thermal insulation film, reflective film optical precision coating machine

4. Thermal sublimation transfer paper, photo paper, PP paper, advertising consumables coating machine

5. Label, double side, masking, foam, car sticker, wallpaper, self adhesive tape coating and laminating machine

Adhesive tape or film roll deep processing equipment

1. Slitting and rewinding machine

2. Cutting machine

3. Laminating and Inspection machine

4. Packing machine

Other customized equipment

1. Small type laboratory multi-function coating machine

2. Medical adhesive tape production and R & D coating machine

Advantages :

1. 20 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services;

Hot Searches