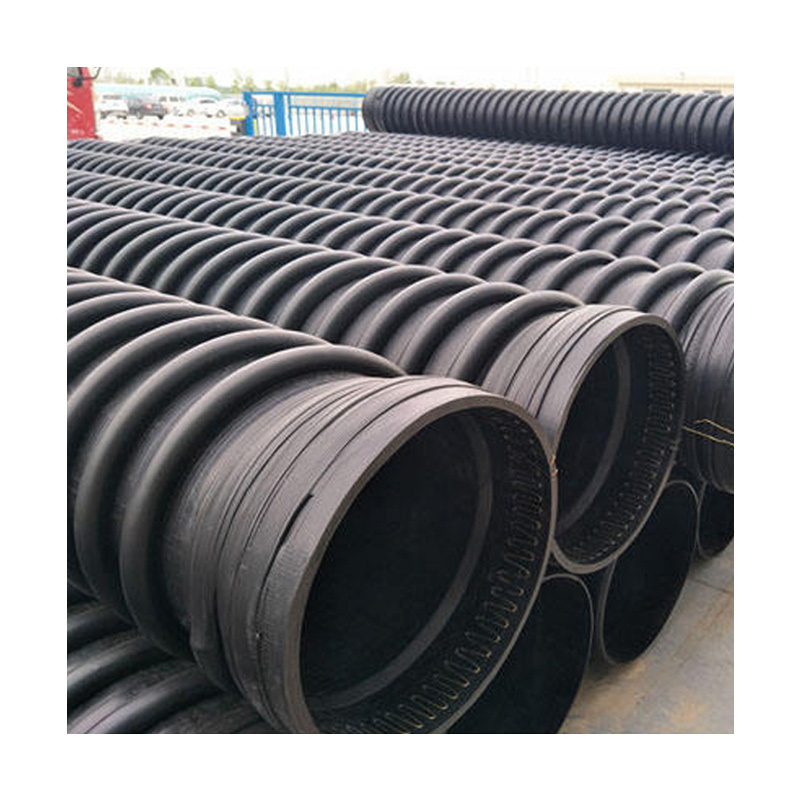

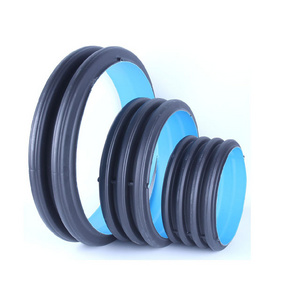

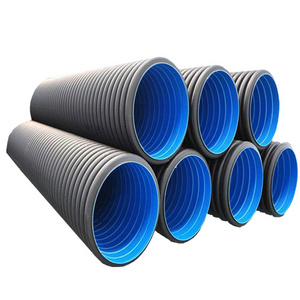

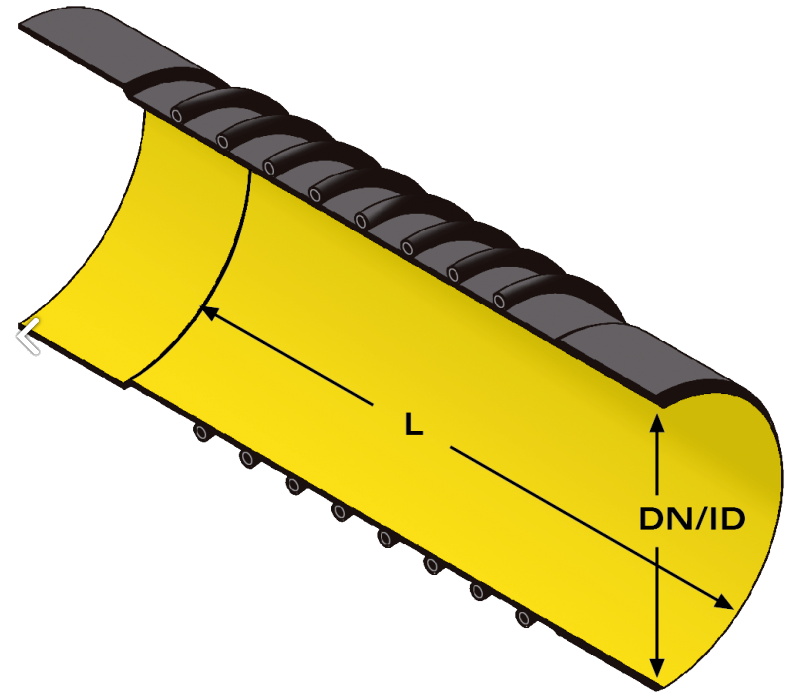

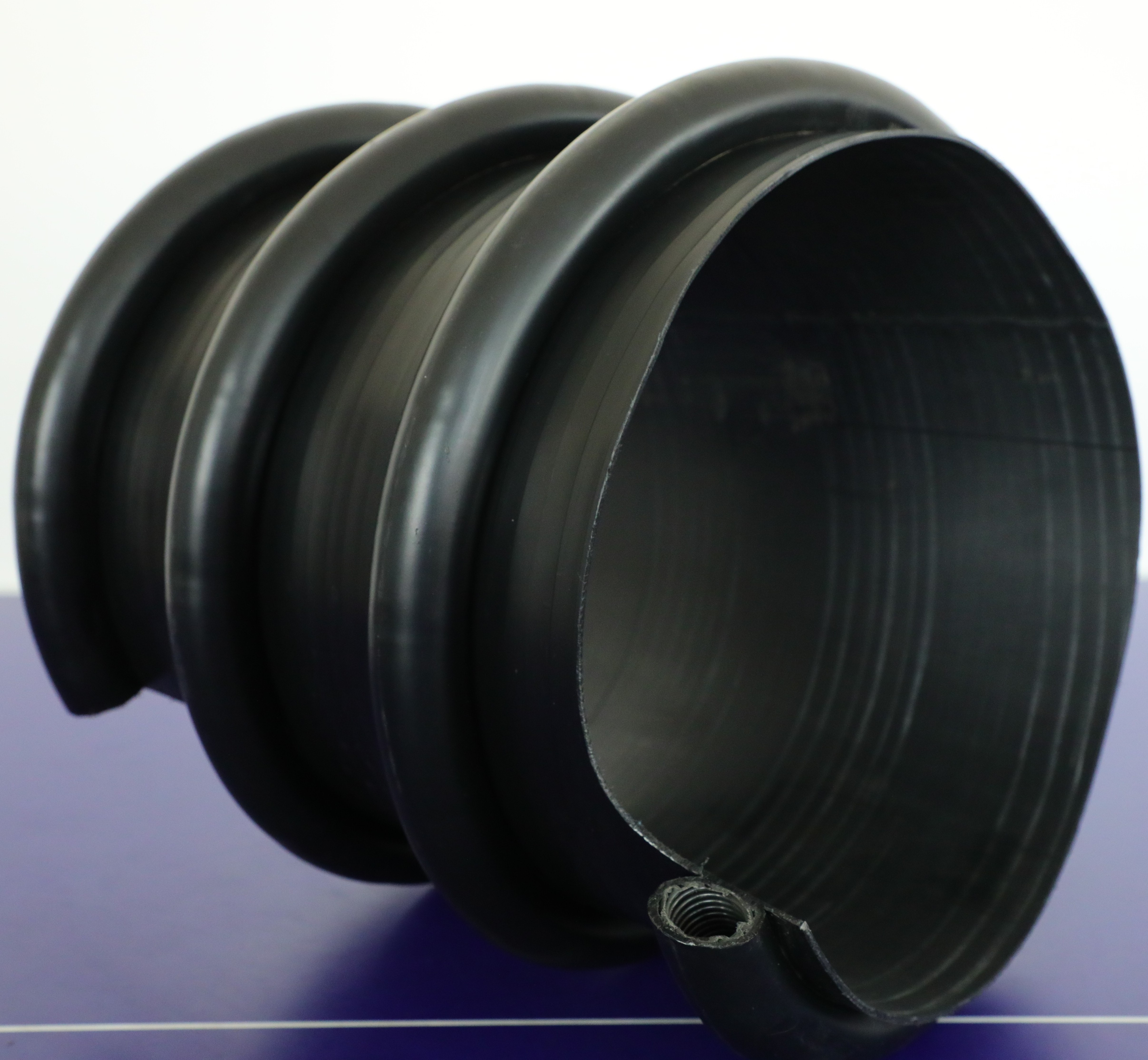

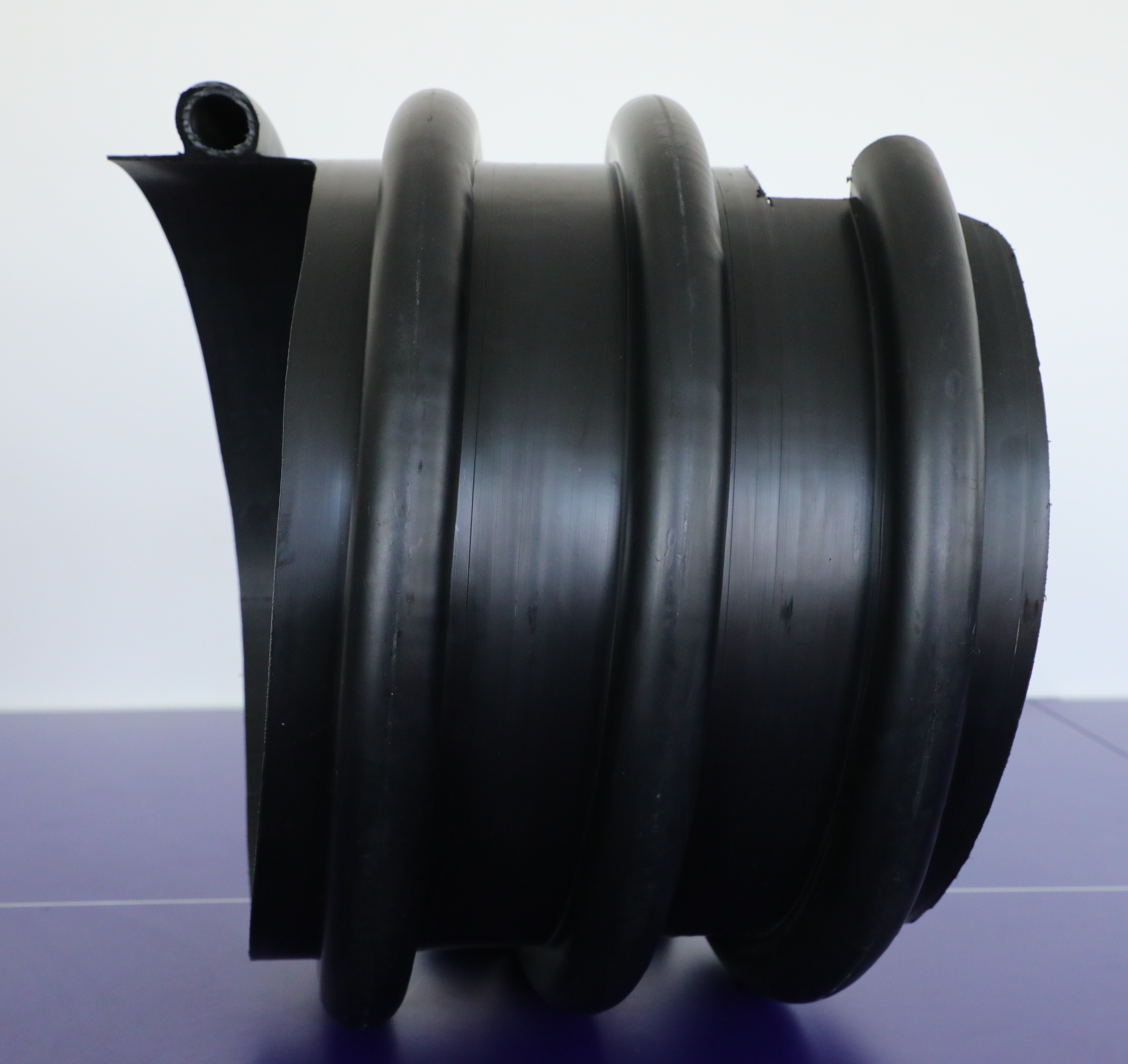

Krah pipe is a kind of special-shaped pipe with smooth inner wall and spiral strengthening outer wall. Spigot and socket Krah pipe normally divided into B type and C type, which are green and flexible, use high density polyethylene as raw material, produced by filament winding process in the states of hot-melt, gradually cooled by means of rolling air cooling and spraying in thermal state and before demolding. It is available for a wide range of diameters from 300 mm to 3000 mm, can be connected by socket-joint. Krah pipe has all the features: high strength, light weight, corrosion resistance, no leakage, good sealing and easy construction etc., be widely used in drainage projects.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

200-4000mm

-

Specification:

-

200-4000

-

Length:

-

6m or customized

-

Thickness:

-

SDR13

-

Standard:

-

According to GB/T19472.2-2017

-

Product name:

-

ZHUOSHI Winding Structure Wall Polyethylene Pipe

-

Application:

-

Drainage, Sewerage, Rain Piping system

-

Life span:

-

50 Years underground

-

Connection method:

-

Electric melting

-

Key word:

-

Krah pipe

-

PAYMENT:

-

T/T 30%deposit 70%before Shipment

-

Raw material:

-

PE 100

-

Certification:

-

ISO9001:2000/ISO14001:2004

-

OEM:

-

YES

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHUOSHI

-

Model Number:

-

200-4000mm

-

Specification:

-

200-4000

-

Length:

-

6m or customized

-

Thickness:

-

SDR13

-

Standard:

-

According to GB/T19472.2-2017

-

Product name:

-

ZHUOSHI Winding Structure Wall Polyethylene Pipe

-

Application:

-

Drainage, Sewerage, Rain Piping system

-

Life span:

-

50 Years underground

-

Connection method:

-

Electric melting

-

Key word:

-

Krah pipe

-

PAYMENT:

-

T/T 30%deposit 70%before Shipment

-

Raw material:

-

PE 100

-

Certification:

-

ISO9001:2000/ISO14001:2004

-

OEM:

-

YES

Products Description

Good quality driveway culvert pipe for sale hdpe krah pipe for drainage plastic culvert pipe

Specification

|

Nominal OD

(dn)

|

Min. mean diameter

|

The wall thickness of the min. layer pressure

|

Min. inner wall thickness

|

|

mm

|

mm

|

mm

|

mm

|

|

200

|

196

|

1.5

|

1.7

|

|

300

|

294

|

1.7

|

2

|

|

400

|

392

|

2.3

|

2.5

|

|

500

|

490

|

3

|

3

|

|

600

|

588

|

3.5

|

3.5

|

|

700

|

673

|

4.1

|

4

|

|

800

|

785

|

4.5

|

4.5

|

|

900

|

885

|

5

|

5

|

|

1000

|

985

|

5

|

5

|

|

1100

|

1085

|

5

|

5

|

|

1200

|

1185

|

5

|

5

|

|

1300

|

1285

|

6

|

5

|

|

1400

|

1385

|

6

|

5

|

|

1500

|

1485

|

6

|

5

|

|

1600

|

1585

|

6

|

5

|

|

1700

|

1685

|

6

|

5

|

|

1800

|

1785

|

6

|

5

|

|

1900

|

1885

|

6

|

5

|

|

2000

|

1985

|

6

|

6

|

|

2100

|

2085

|

6

|

6

|

|

2200

|

2185

|

7

|

7

|

|

2300

|

2285

|

8

|

8

|

|

2400

|

2385

|

9

|

9

|

|

2500

|

2485

|

10

|

10

|

|

2600

|

2585

|

10

|

10

|

|

2700

|

2685

|

12

|

12

|

|

2800

|

2785

|

12

|

12

|

|

2900

|

2885

|

14

|

14

|

|

3000

|

2985

|

14

|

14

|

Physical performance:

|

Item

|

Product Parameter

|

|

Ring stiffness (KN/m 2 )

|

SN4 ≥ 4, SN8 ≥ 8, SN16 ≥ 16

|

|

Impact performance

|

TRL ≤ 10%

|

|

Ring flexibility

|

No delamination, no cracking, no buckling deformation, no dents, no bulges

|

|

Creep rate

|

≤4

|

|

Tensile strength of Seams

DN/ID ≤ 300 400 ≤ DN/ID ≤ 500 600 ≤ DN/ID ≤ 700 DN/ID ≥ 800 |

The Minimum endurable tensile force (KN)

≥ 380 ≥ 510 ≥ 760 ≥ 1020 |

|

Oven test

|

No delamination, no cracking on the seams

|

Advantages

3. No Leakage

4. Higher flow capacity

5. Convenient for construction and installation

6. Lower

system and maintenance costs

7. Longevity of working life

8. Carat Tube is recycled and Environment-friendly

Product packaging

Applications

1.Underground drainage, sewage, aeration and others in municipal construction areas;

2.Drainage for railway, highway, court and others in road engineering areas;

3.Nuclear power plants, steel mills, power plants, petrochemical plants, docks, stations;

4.Tidal flat, saline pool, riverbed, soft foundation expansive soil, earthquake zone and others in adverse environmental areas.

Installation Instructions

Recommend Products

Hot Searches