Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Standard or Nonstandard:

-

Standard or Nonstandard

-

Product name:

-

Oil Seal

-

Size:

-

Custom Size

-

Feature:

-

Durable

-

Type:

-

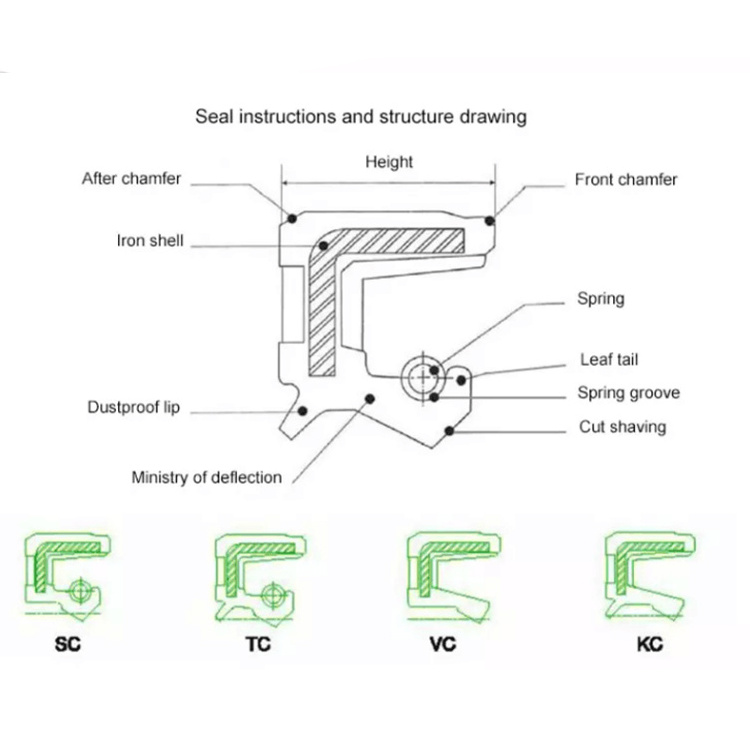

TC,SC,DC

-

Hardness:

-

Shore A 60-75

-

Material:

-

Rubber, NBR,FKM,Silicone,HNBR,EPDM

-

Medium:

-

Oil, Water and Dust

Quick Details

-

Place of Origin:

-

Jiangsu, China, Jiangsu, China (Mainland)

-

Brand Name:

-

SXAN

-

color:

-

any

-

Standard or Nonstandard:

-

Standard or Nonstandard

-

Product name:

-

Oil Seal

-

Size:

-

Custom Size

-

Feature:

-

Durable

-

Type:

-

TC,SC,DC

-

Hardness:

-

Shore A 60-75

-

Material:

-

Rubber, NBR,FKM,Silicone,HNBR,EPDM

-

Medium:

-

Oil, Water and Dust

Customized rubber oil seal

Customized rubber oil seal

We are a manufacturer mainly specialize in producing different types of O-rings,rubber oil seal,customized rubber products.The materials are available in NBR,SILICONE,FKM,EPDM,HNBR and so on.

We have thousands of available oil seals and O-ring moulds in stock and sample is free from our stock. We can also open new moulds as customers' drawings or physical sample for standard or non-standard o rings and other rubber parts.

| Material | NBR ,SILICONE,EPDM,FKM,HNBR,etc |

| Color | Black, Transparent, White, red, green, as customers' requirement |

| Size | customers requirements |

| Hardness | 30-90 shore according to work environment |

| Service | OEM or ODM |

| Production basis | Samples or drawings |

| Technology | compression, injection or extrusion |

| Working temperature | -60-350 Celsius degree |

| Tolerance | ±0.05mm |

| Density | 1.0-2.0g/cm² |

| MOQ | 100 pcs rubber oil seal |

| Working life | 10-30years |

| Sample | Sample is free from stock |

| Application | Mechanical equipment. Automotive ,Construction,Home appliance,Aviaiton,Office facilities and so on |

| performance |

1.Good sealing and damping

2.Water resistance 3. Anti-aging 4.Anti- ozone 5.oil resistant 6.pressure resistant |

| Common types of oil seals | |||||

| Type | Code number | Main features | Usage | Dielectric pressure resistance | Maximum line speed |

| Simple single lipped | B | It is commonly used for high and low speed rotating shafts and reciprocating movement to seal mineral, oil and water. | Ordinary oil seal, in the case of less dust and impurities, the use of medium pressure, the reciprocating speed of <0.1m/s. | <0.05MPa | 15m/s |

| Regular lip | FB | In addition to the characteristics of the above S type oil seal, dust can be prevented. | Ordinary oil seal, with dustproof lips, dustproof, resistant to medium pressure | <0.05MPa | 15m/s |

| No spring type | BV | Spring free single lip type inner frame type rubber oil seal . | Generally applicable to low-speed conditions, the sealing medium for the lubrication of ester. | <0.05MPa | 6m/s |

| Outer skeleton, single lip | W | With the spring single lip exposed skeleton rubber oil seal , waist thin, follow good, good rigidity. | Ordinary oil seal , used in case of less dust and impurities | <0.05MPa | 15m/s |

| Outer skeleton, double lips | FW | With the lips of the lips exposed, skeleton rubber oil seal , waist thin, followed by good, high stiffness, good coaxial. | Ordinary oil seal, with dustproof lips, dustproof, resistant to medium pressure <0.05 | <0.05MPa | 15m/s |

| Fabricated single lipped | Z | From the inside and outside the outer skeleton oil seal skeleton assembly into piping and installation of high precision, fast heat dissipation, heavy load characteristics. | Suitable for heavy load under high temperature and high speed condition | <0.05MPa | 15m/s |

| Fabricated double lipped | FZ | The assembled external skeleton oil seal with side lip has the characteristics of dust resistance, high installation accuracy, fast heat dissipation and heavy load characteristics. | Apply to high temperature, high speed, heavy load under dust condition | ≤0.05MPa | 15m/s |

| Unidirectional reflux type | Dextral SR,Levo DL | A diagonal bar with angle in lip air measurement system using fluid mechanics principle, produces pump function, with reflux effect. | Because of the backflow effect, the radial force is smaller than that of the ordinary oil seal , thereby reducing wear and heat build-up and improving service life | <0.05MPa | 20m/s |

| Pressure type | NY | The lip is short, stubby waist, with pressure, work pressure is less than 3MPa. | The shaft end oil seal for high pressure pump, general PV value is less than or equal to 8 | ≤3MPa | 15m/s |

Q 1.Which Payment way is workable?

A: Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

B: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

C: L/C ( Irrevocable LC at sight: Order amount over USD10,000)

Q 2. What is the normal lead time for product orders?

A: Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10 days, average production time after sample approval is 2-3 weeks.

Q 3. What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

A2: We have various rubber compounds approved by UL, ,, KTW, W270, WRAS, ACS, AS4020, EN681, EN549, ROHS and REACH.

Q 4: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

Q 5: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, ISO2768, etc.

Q 6:Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in case of an order.