- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

Polyurethane Sandwich Panel

-

Product name:

-

Safe polyurethane sandwich panel insulation roof panel 150mm

-

Steel Thickness:

-

0.4-0.7mm

-

Core Thickness:

-

50-200mm

-

Material:

-

Galvanzied Steel

-

Core material:

-

Hard Polyurethane Foam

-

Length:

-

11.8m

-

Density:

-

40-42kg/m3

-

Zero Risk Commitment:

-

Can be return in 15 Days/Exchanged in 3 Mouths /Warranty in 3 Years

-

Cooperation Policy:

-

Recruited a Global Agent

Quick Details

-

Project Solution Capability:

-

graphic design

-

Application:

-

Workshop

-

Design Style:

-

Modern

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

Polyurethane Sandwich Panel

-

Product name:

-

Safe polyurethane sandwich panel insulation roof panel 150mm

-

Steel Thickness:

-

0.4-0.7mm

-

Core Thickness:

-

50-200mm

-

Material:

-

Galvanzied Steel

-

Core material:

-

Hard Polyurethane Foam

-

Length:

-

11.8m

-

Density:

-

40-42kg/m3

-

Zero Risk Commitment:

-

Can be return in 15 Days/Exchanged in 3 Mouths /Warranty in 3 Years

-

Cooperation Policy:

-

Recruited a Global Agent

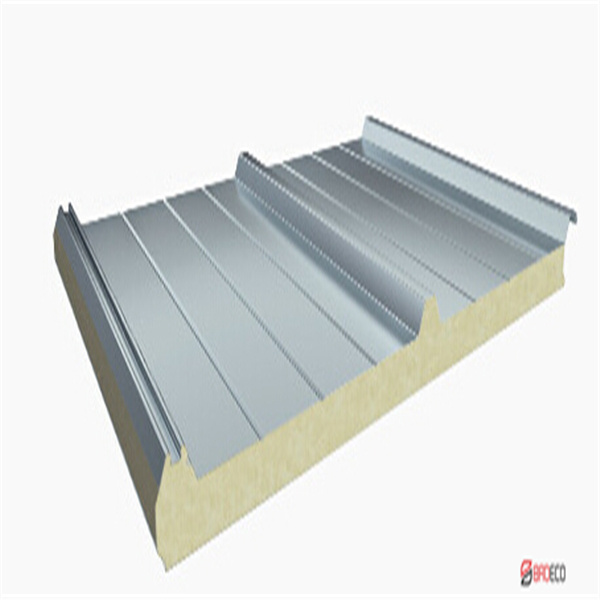

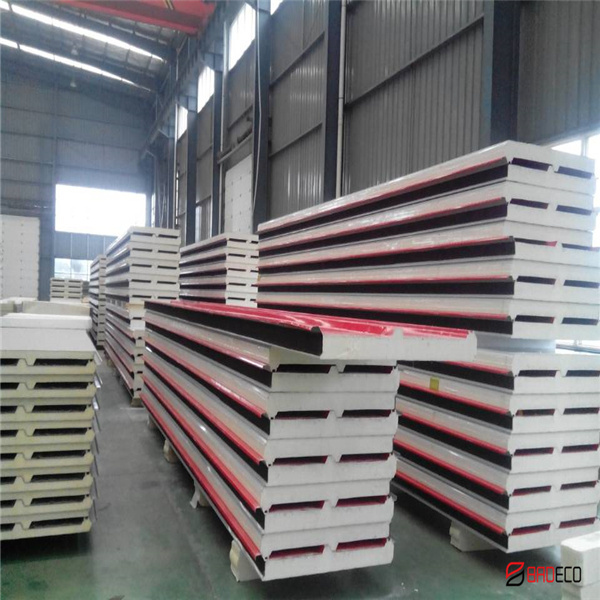

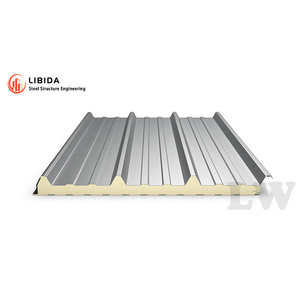

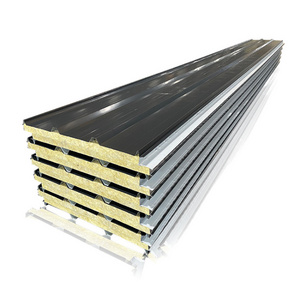

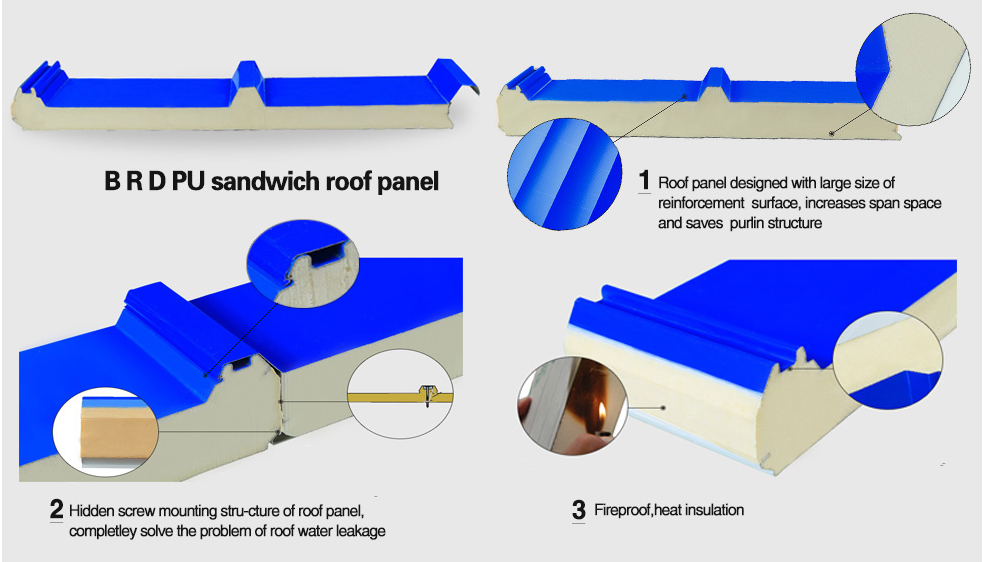

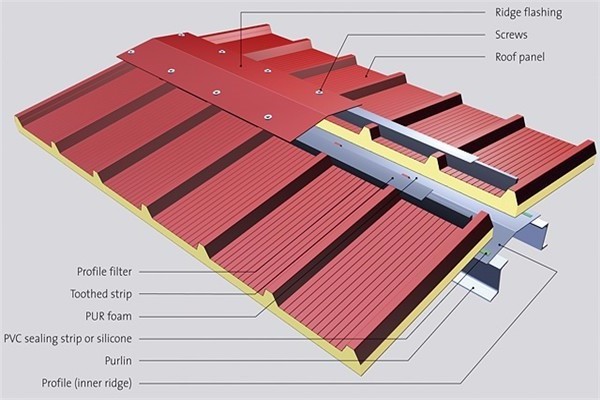

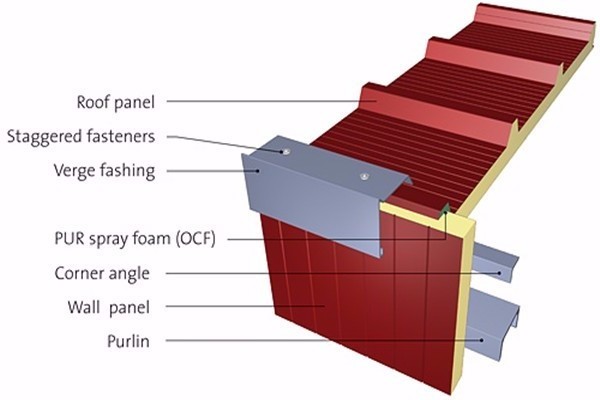

PU Sandwich Roof Panel

As a new material in structure, the polyurethane roof panel has been the most suitable choice for many users. The polyurethane roof panel is divided into two types: The three waves of polyurethane composite roof panel, The four waves of polyurethane composite roof panel. The characters of PU roof panel are heat insulation, waterproof, soundproof, and easy to install. The excellent function is the reason that so many people choice it as roof board.

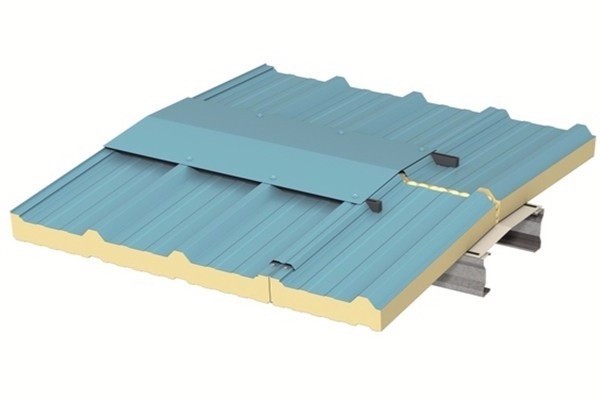

1. Created exclusively 4 wave roof panel in China for the first time, more powerful for snow load.

2. Exclusively adopt the 3 wave roof, embedded installation, dark nail waterproof technology, easy installation, guarantee 100% hold water.

3.Adopt the 40 cm peaks, increase the surface strength, easy drainage, reducing both snow load and wind load by 170%.

4.Super flame retardation

The coefficient of thermal conductivity is 0.023w/(m•k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits.

5. Easy and quick installation

Compared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.

1, First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

2, Before the installation of polyurethane wall panel, it should check whether the verticality and levelness of metope purlin installation requirements, wall frame column vertical degree meets the requirement.

3, Before installation polyurethane wall panel, it should first mounting plate bottom water retaining plate and the bottom of the window to block water board, water retaining plate and wall frame beam connection with self tapping screw fixation.

4, Polyurethane wall panel links with ground.

Lateral links: fixed polyurethane sandwich panel with the ground at the other end of the round hole with steel frame fixed, connection between the two plate mouth involution, if occurrence crack of the connectors available heat preservation to fill.

Vertical links: the gap between plates, using the dedicated button concave groove in the fixed polyurethane wall panel.