- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINNUO

-

Voltage:

-

380V 50Hz 3phases or as your need

-

Dimension(L*W*H):

-

2.5*1.2*1.25m

-

Weight:

-

2.3 kg

-

Feeding width:

-

based on the profile

-

Marketing Type:

-

New Product 2021

-

Name:

-

XN-light frame steel keel roll forming machine

-

Raw material:

-

galvanized

-

Shaft material:

-

45# St

-

Roller material:

-

Cr12

-

Application:

-

Industiral Building

-

Control system:

-

PLC(detla) System

-

Color:

-

based on your need

-

Cutting blade material:

-

Cr12 Mould Steel

-

Cutting type:

-

Flying Cutting

-

Machine type:

-

Auto

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

35-50m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINNUO

-

Voltage:

-

380V 50Hz 3phases or as your need

-

Dimension(L*W*H):

-

2.5*1.2*1.25m

-

Weight:

-

2.3 kg

-

Feeding width:

-

based on the profile

-

Marketing Type:

-

New Product 2021

-

Name:

-

XN-light frame steel keel roll forming machine

-

Raw material:

-

galvanized

-

Shaft material:

-

45# St

-

Roller material:

-

Cr12

-

Application:

-

Industiral Building

-

Control system:

-

PLC(detla) System

-

Color:

-

based on your need

-

Cutting blade material:

-

Cr12 Mould Steel

-

Cutting type:

-

Flying Cutting

-

Machine type:

-

Auto

-

Certification:

-

CE/ISO9001

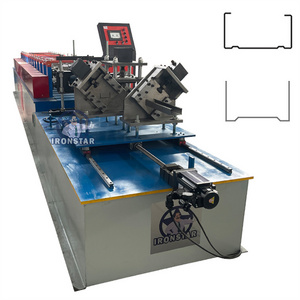

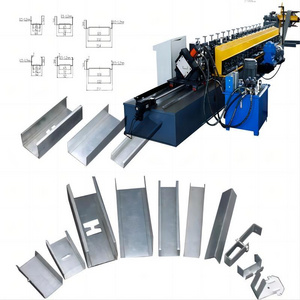

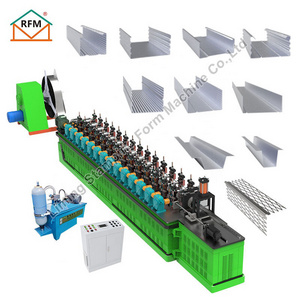

drywall system drywall studs roll forming machine customized drywall system drywall studs roll forming machine

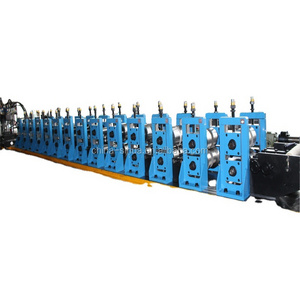

1: Configuration

Uncoiler 1 set

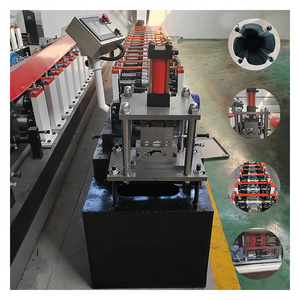

Roll forming roller: about 12 groups

PLC control system 1 set

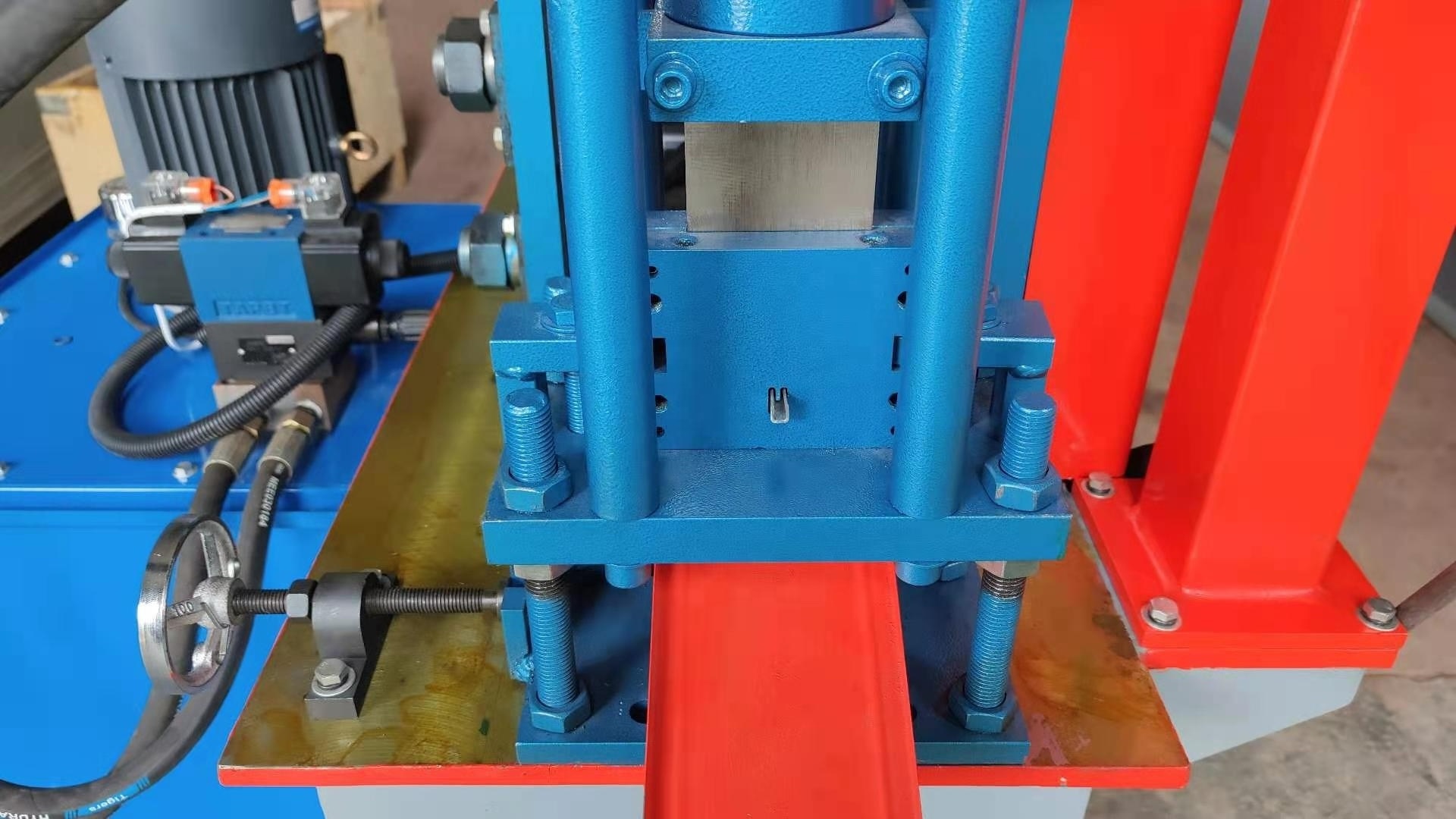

Hydraulic cutting system: 1 set

Collection table

2 : Working Process Flow:

Uncoiling-Coil feeding-Guiding-Roll Forming-Punching (if needed) - Cutting-Collection table

3: Technical Parameters:

A: Power supply :

380V, 3 phases, 50 Hz (can be adjusted according to actual power supply conditions in different countries)

Main motor power: 7.5KW

Pump power: 4kw

B:Uncoiler:

Inner diameter: 500mm

Outer diameter: 1100mm

loading weight: 5t

C:Forming part:

Feeding thickness: 0.3-1mm

Feeding width: 1000mm

Forming speed: 10-12m/min

Cutting Deviation: 10m±2mm

No. of Roller station: 12 groups

Roller material: Cr12

Material of shaft: 45# steel with heat treatment

Diameter of shaft: 72-90mm

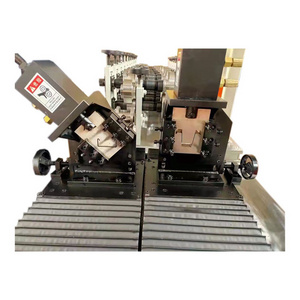

D:Hydraulic System:

Hydraulic pressure: 10-12 Mpa

Cutter material: Cr12

E:Control system :

Full-automatic NC-PLC control system

Control channel: Colored touch screen

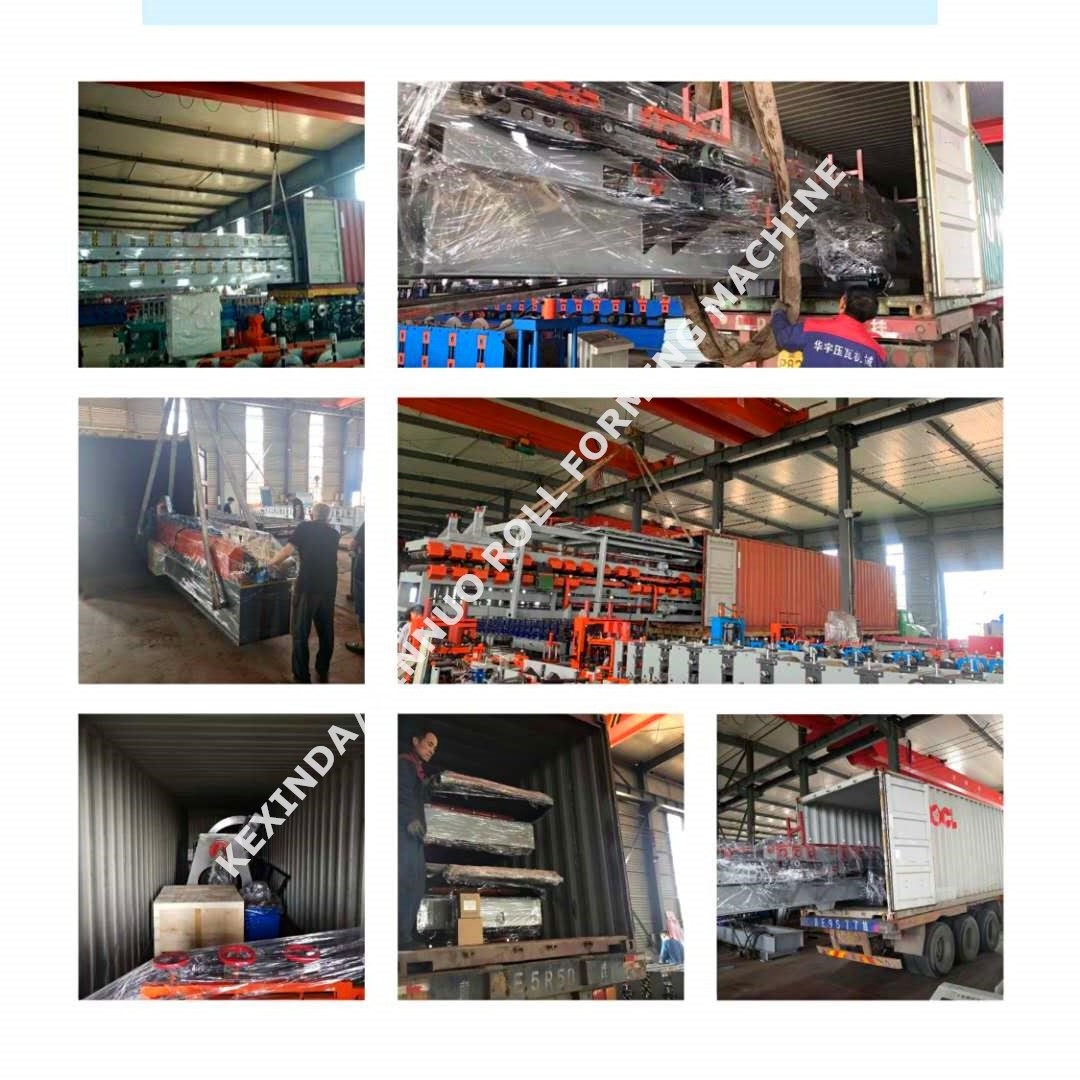

control box is packed with wooden packaging.

Delivery Detail: about 45 days.

Packaging Details : Main machine is nude in the container, the computer

1:Engineers available to install and test the machinery for you overseas in your factory.

2: Warranty: 12 months.

3:Technical guidance for free forever.