- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Color:

-

Customized Colors

-

Size:

-

Customized Size

-

Certification:

-

ISO9001:2015 / ISO13485:2016 / IATF16949:2016

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Mould life:

-

300000-500000 Shots

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Sample:

-

Available

-

OEM/ODM:

-

Accecpted

Quick Details

-

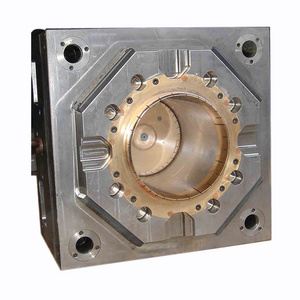

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Qualigie

-

Model Number:

-

Customized

-

Color:

-

Customized Colors

-

Size:

-

Customized Size

-

Certification:

-

ISO9001:2015 / ISO13485:2016 / IATF16949:2016

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Mould life:

-

300000-500000 Shots

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Sample:

-

Available

-

OEM/ODM:

-

Accecpted

About Qualigie

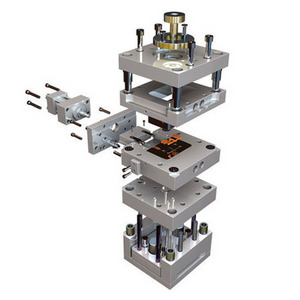

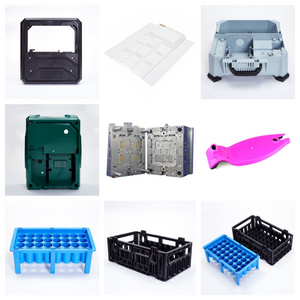

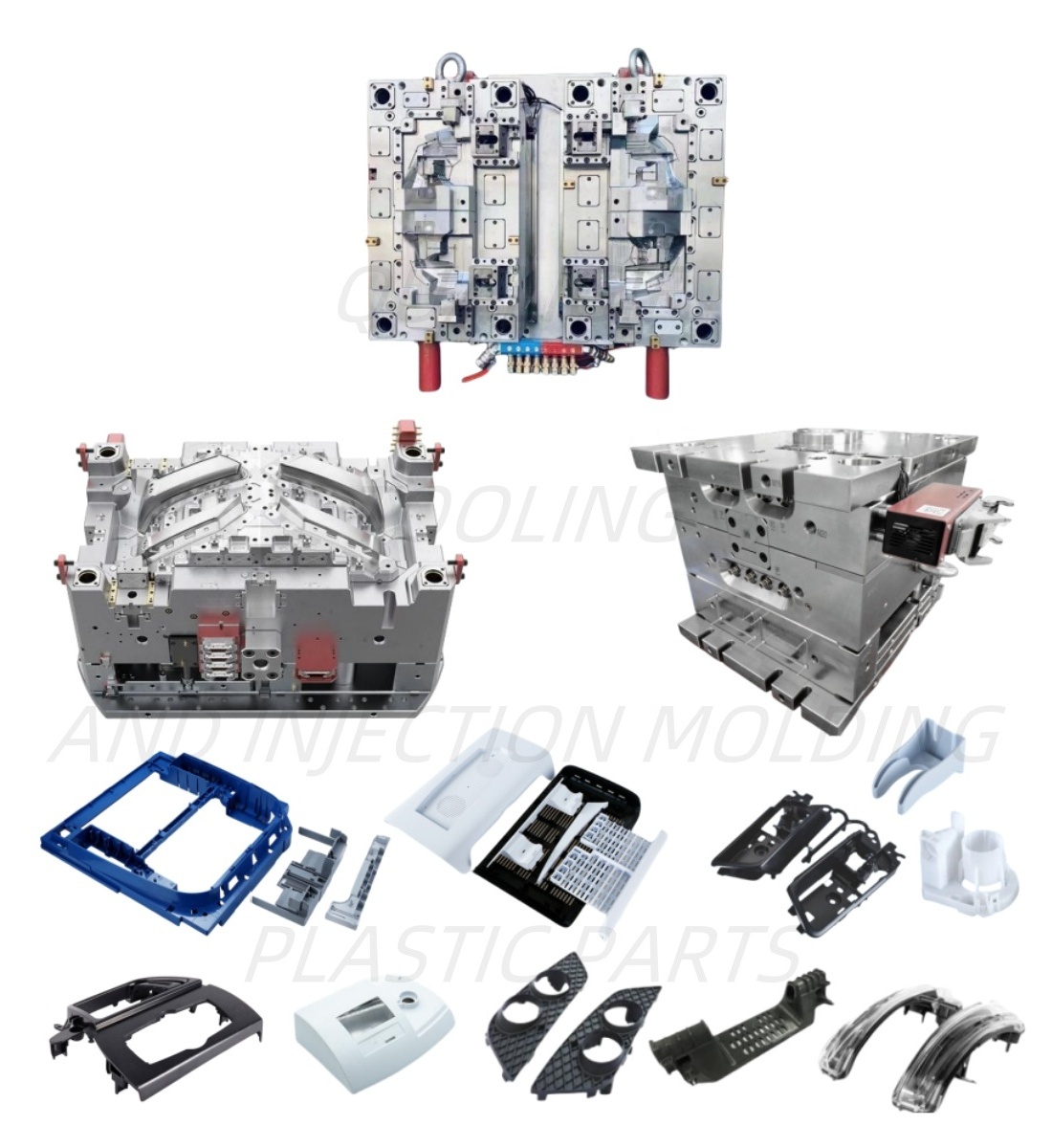

Products Description

|

Company Name

|

Xiamen Qualigie Rapid Technologies Co., Ltd.

|

|

|

|

|||

|

Product Name

|

Plastic Injection Molded Parts

|

|

|

|

|||

|

Plastic Material

|

ABS, ABS V0, PC, PC V0, PC/ABS, PC+GF, POM(Derlin), PP, PA6,PA66, PA12, PA12+GF, PE, HDPE, PMMA(Acrylic), PVC, PEI, PBT, PPS, PET, PPO, TPU, TPE, etc.

|

|

|

|

|||

|

Color

|

White, Black, Green, Blue, Yellow, Clear, etc.

|

|

|

|

|||

|

Product Weight

|

Ranging from 1g to 5000g

|

|

|

|

|||

|

Application

|

Qualigie's injection molding serves a wide range of industries, including aerospace, automotive, medical devices, consumer goods, electronics, robotics, toys, etc.

|

|

|

|

|||

|

Injection Molding Options

|

Plastic injection molding, Insert molding, Overmolding, 2K injection molding

|

|

|

|

|||

|

Cavity QTY

|

Single / multi

|

|

|

|

|||

|

Runner

|

Cold / Hot

|

|

|

|

|||

|

Mould Precision

|

+/-0.01mm

|

|

|

|

|||

|

Mould Life

|

100K-1000K shots as per customer's requirement.

|

|

|

|

|||

|

Manufacturing Equipment

|

High speed CNC, Standard CNC, Wire Cutting, EDM, WEDM, Precision Grinder, Drilling Machine, Plastic Injection Molding Machine from 130T to 1200T, etc.

|

|

|

|

|||

|

Surface Treatment

|

Polishing, Texture, Glossy, Chroming, Silk-screen Printing, Pad Printing, Laser marking, Sandblasting, Rubber Painting, etc.

|

|

|

|

|||

|

Design Software

|

Pro-E, Solidworks, UG, CATIA, CAD, CAM, etc.

|

|

|

|

|||

|

Quality System

|

ISO9001:2015 / ISO13485:2016

|

|

|

|

|||

|

Principle

|

High Quality, Professional Service, Low Price, Fast Delivery

|

|

|

|

|||

Qualigie's injection molding serves a wide range of industries, including aerospace, automotive, medical devices, consumer goods, electronics, robotics, toys, etc.

Tooling and Injection Molding Process

Our Factory

Qualigie is one of the most reliable injection molding companies, specializing in custom mold design, mold making, production and finishing at highly competitive prices. With our state-of-the-art facility and high-skilled engineers, we are committed to delivering high quality service and products to our customers.

We focus on every engineering detail and design specification in tooling and injection molding, including material, tolerance, appearance, assembly, etc. You can rely on Qualigie to provide superior precision injection molding services to meet your unique needs and specifications. Additionally, we are flexible and be able to support both low-volume run and high-volume production.

Why Choose Us

Strong Manufacturing Capability

We have many kinds of different injection machines, allowing us to be flexible to produce all kinds of parts for you. Our clean room (dust free workshop) is used in the production of medical devices, that can help to ensure that these products are of high

quality and safe for use.

quality and safe for use.

Material Selection

We help guide customers through the material selection process to find cost effective solutions for their application requirements and physical principles. We always review and consult on injection molding material selection before start tooling and production.

Design Optimization

With 15+ years of experience in the injection molding industry, our engineer team are dedicated to working with you to have comprehensive DFM review and improving the existing design to be more efficient for manufacturing and more durable to be used.

Quality Control

Our injection molding factory is certified to ISO 9001. We have a good quality control system to monitor our injection molding processes to ship high quality products to you, ensure that your products achieve large scale customers satisfaction.

➪

Fast Delivery

➪

Cost-effective

➪

Low and high volume

➪

ISO9001:2015 / ISO13485:2016

certificated

Payment & Shipping

FAQ

Q1. Are you a trading company or a manufacturer?

A1: We are a manufacturer as you can see our workshop as above.

Q2: What is the minimum order qty?

A2: There is no minimum order quantity, but order prices will be more competitive for higher order quantities.

Q3. How long does it take to make molded parts?

A3: It takes about 35 days for mold design and tooling. And it takes within 7 days for molded parts production, a little longer for special material purchasing.

Q4: How much does your injection molding service cost?

A4: Normally, the price for custom injection molding parts varies according to the size and design of components, mold cavity quantities, tolerance and finishing requirement.

Q5: Can we know the tooling schedule without visiting your factory?

A5: After we get the order, we will send you the tooling schedule. During the tooling process, we will update you with weekly reports and related pictures. Therefore, you can clearly understand the tooling schedule.

Q6: How do you guarantee your quality?

A6: Qualigie has a complete quality system and is ISO 9001:2015 certified. Each key dimension is measured by our QC department using 3D CMM during the whole tooling process. We provide First Article Inspection report (FAI report) to prove the mold we made is what the client requested.

Contact Us

|

Services

|

Prototyping and Manufacturing

|

|

|

|

|||

|

Email

|

nicole@qualigie.com

|

|

|

|

|||

|

Tel

|

+86-592-5992917

|

|

|

|

|||

|

Web

|

www.qualigie.com

|

|

|

|

|||

Hot Searches