Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

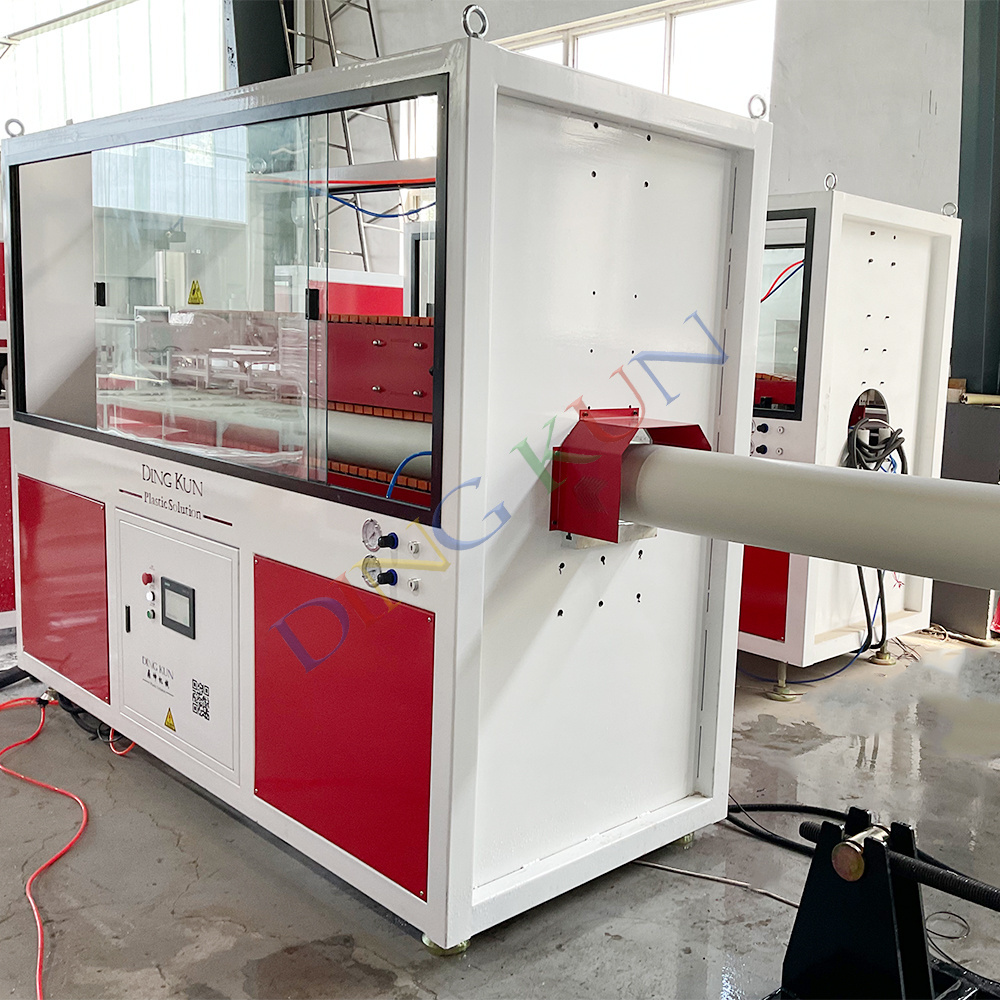

Dingkun

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

23x2x4 Meters

-

Power (kW):

-

37

-

Weight:

-

8000 KG

-

Name:

-

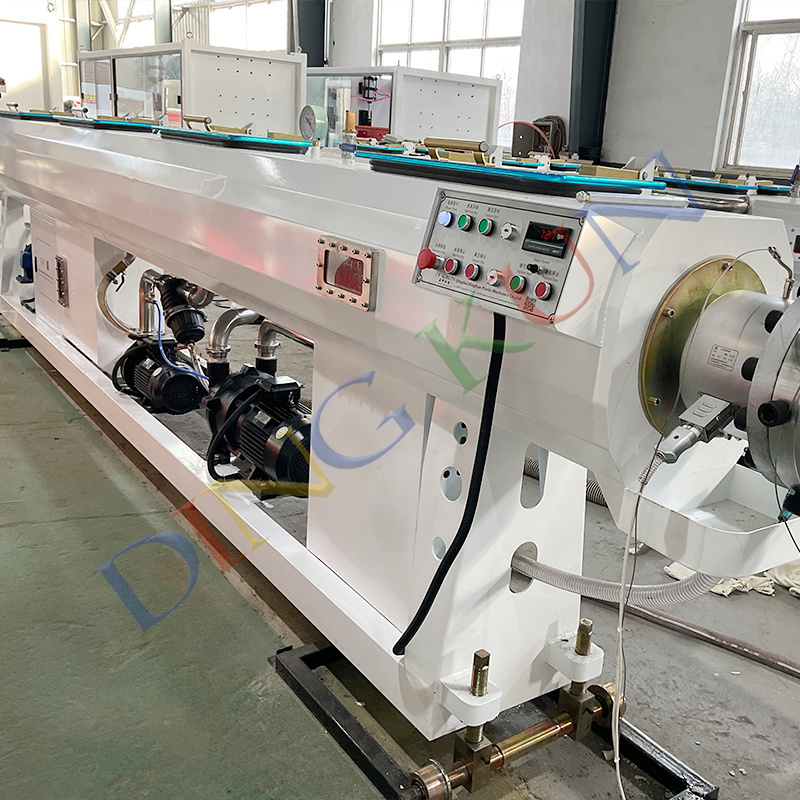

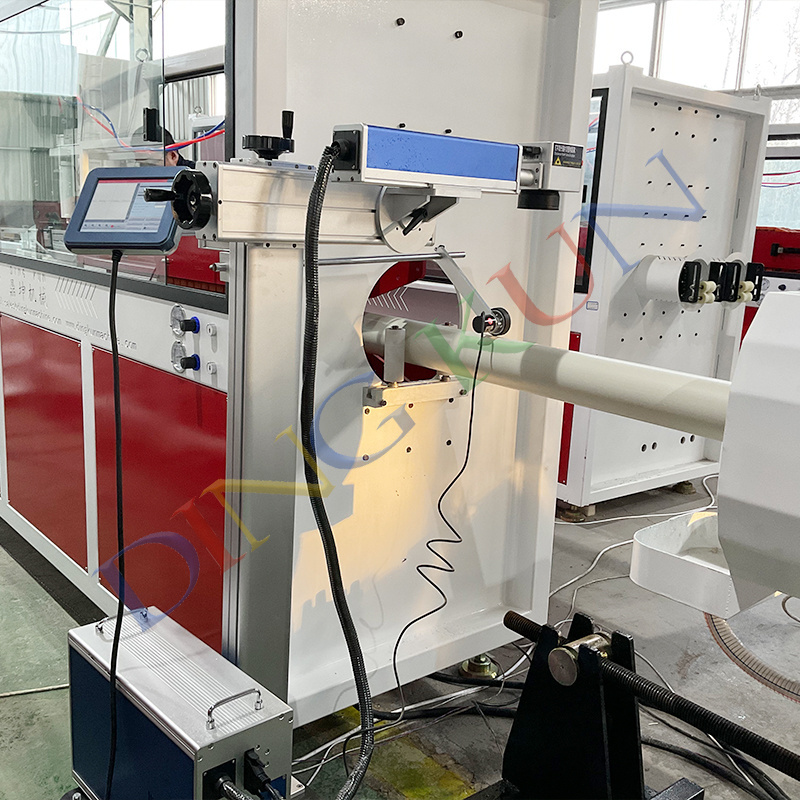

PVC pipe plastic extruder machine

-

Model Number:

-

SJSZ-65/132

-

Control:

-

SIEMENS PLC+Touch Screen

-

Motor:

-

SIEMENS Brand

-

Screw type:

-

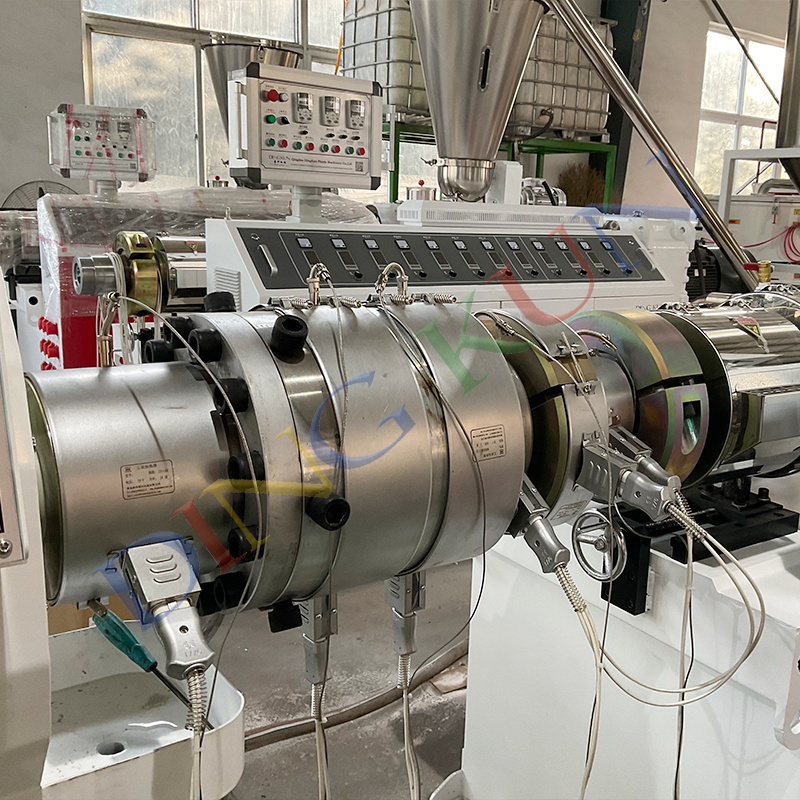

Twin Conical Screw

-

Inverter brand:

-

Switzerland "ABB" Brand

-

Gear box:

-

DELING

-

Contactor:

-

SIEMENS

-

Temperature controller:

-

Omron Brand

-

Capacity:

-

150-250kgh

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

37 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dingkun

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

23x2x4 Meters

-

Power (kW):

-

37

-

Weight:

-

8000 KG

-

Name:

-

PVC pipe plastic extruder machine

-

Model Number:

-

SJSZ-65/132

-

Control:

-

SIEMENS PLC+Touch Screen

-

Motor:

-

SIEMENS Brand

-

Screw type:

-

Twin Conical Screw

-

Inverter brand:

-

Switzerland "ABB" Brand

-

Gear box:

-

DELING

-

Contactor:

-

SIEMENS

-

Temperature controller:

-

Omron Brand

-

Capacity:

-

150-250kgh

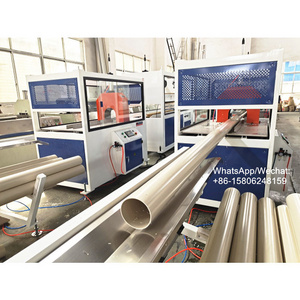

PVC Pipe Plastic Machinery / Production Line / Extrusion Machine

This line can be used in the area of cable pavement pipes production. Whole line consists of conical twin screw extruder, mould, vacuum calibration cooling tank, haul-off, cutter, tripping table /belling machine,etc. And the line can be equipped with PLC control, ink-jet/laser printer, crusher, shredder, Pulverizer ,water chiller, air compressor etc. Advanced design for screws and barrel supplies powerful safeguard for the PVC plasticization.

Produce process :

PVC powder + additive → mixing → screw feeding → twin screw extruder → mould and calibrator → vacuum forming machine → haul off machine → cutting machine → stacker

PVC powder + additive → mixing → screw feeding → twin screw extruder → mould and calibrator → vacuum forming machine → haul off machine → cutting machine → stacker

PRODUCT SPECIFICATIONS

|

Model

|

PVC Pipe Machine

|

|

Diameter Range

|

63 mm, 75 mm, 90 mm,110 mm,125 mm,140 mm,160 mm

|

|

Extruder Model

|

SJSZ65

|

|

Mold Design

|

Single Cavity Design

|

|

Extruder Capacity

|

150-250kg/h

|

|

Motor Power

|

37kw

|

|

Auto Material Feeder

|

To feed material into extruder

|

|

Twin Screw Extruder

|

World famous brand electrical component such as Siemens, Schneider, ABB etc

High torque gearbox

Siemens motor achieved global after service;

Zhousan screw and barrel;

Intelligent PLC controlling system with human-friendly interface.

|

|

Die head & Mold

|

40Cr material

Complete set include extrusion die head, Slotting & water ring type calibration sleeve

Apply to PVC single,dual,Four cavity extrusion.

|

|

Vacuum calibration tank

|

Include full set of vacuum and water pump

length 6000mm

|

|

Haul off

|

Upper and lower caterpillar is driven separately by the frequency inverter

|

|

Cutter

|

No dust cutter:enter knife by hydraulic drive

Cutting saw: steel alloy, specific for cutting U-PVC pipe.

Equipped cast aluminum compacted block for accurate cutting

Synchronous control

|

|

Stacker

|

Stainless steel as touching material

Discharge driving by air cylinder

|

Hot Recommend

WPC Foam Board Machine

WPC Decking Machine

PVC Roof Sheet machine

Delivery

Exhibition & Customers

Certifications

Service

FAQ

Q: Your company is an industrial manufacture factory or a transactional company ?

A: DingkunCompany is an industry manufacture of Extrusion Machines.

Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control

A: DingkunCompany is an industry manufacture of Extrusion Machines.

Q:All of your products are made by your self or compacted via purchasing the others?

A: we have independent technical team who focus on design & development & Manufacture extrusion machines. all the products are made by our technical team.

A: we have independent technical team who focus on design & development & Manufacture extrusion machines. all the products are made by our technical team.

Q:Annual Production Capacity( Previous Year)

A: About 80 lines and total revenue is about USD 2500000

A: About 80 lines and total revenue is about USD 2500000

Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control

Q:Do the QA/QC inspectors work independently from the production line?

A: Yes

A: Yes

Q:How many QA/QC inspectors in total?

A: 4

Execellent Service-Turnkey Project (Pre-Sale and After-Sale Service)

A: 4

Execellent Service-Turnkey Project (Pre-Sale and After-Sale Service)

Hot Searches