- Product Details

- {{item.text}}

Quick Details

-

Power:

-

27-100kw

-

Dimension(L*W*H):

-

40 m x 30m x 6m

-

Weight:

-

50000 kg

-

Warranty:

-

18 Months

-

Product name:

-

20-80TPH Bitumen Factory Asphalt Mixing Machine

-

Capacity:

-

20-80t/h

-

Type:

-

Continuous drum mixing asphalt plant

-

Drying drum:

-

Counter current

-

Asphalt elevator:

-

Scraper type

-

Pneumatic system:

-

AIRTAC,TAIWAN, CHINA

-

Control system:

-

SIEMENS,GERMAN

-

Operation:

-

Auto & Manual

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOOMLINE

-

Voltage:

-

220V/380V-50Hz

-

Power:

-

27-100kw

-

Dimension(L*W*H):

-

40 m x 30m x 6m

-

Weight:

-

50000 kg

-

Warranty:

-

18 Months

-

Product name:

-

20-80TPH Bitumen Factory Asphalt Mixing Machine

-

Capacity:

-

20-80t/h

-

Type:

-

Continuous drum mixing asphalt plant

-

Drying drum:

-

Counter current

-

Asphalt elevator:

-

Scraper type

-

Pneumatic system:

-

AIRTAC,TAIWAN, CHINA

-

Control system:

-

SIEMENS,GERMAN

-

Operation:

-

Auto & Manual

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

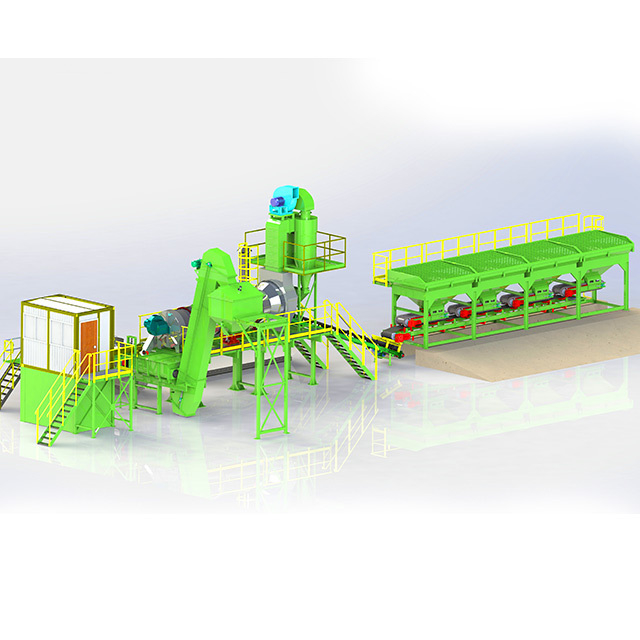

20-80TPH Bitumen Factory Asphalt Mixing Machine

ZAP-C series asphalt mixing plant is the new developed product on the basic of intensive studying the international advanced technology.

ZAP-C drum mix asphalt plant models are available from 20TPH to 80TPH

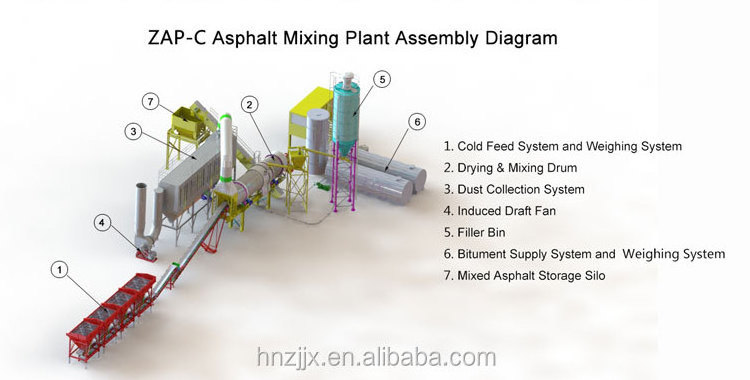

Continuous drum asphalt mixing plant is very different with batch asphalt mixing plant. It produce the asphalt mixture in the drum which also dry the aggregate continuously.

ZAP-C series asphalt drum mix plant has the following features:

1. Ultra low power consumption, large production capacity, fuel consumption is lower under the condition of same capacity.

2. Equipment consistent is simple and with reliability, low failure rate, easy to move and maintain, low equipment investment.

3. Has strong and simple RAP expend ability.

4. Need no installation foundation(only need simple smooth and harden).

5. Kinds of each material successive, can guarantee the continuous of mixing time and space, form flow line production.

6. The application of latest international weighting technology, can guarantee the precision of each material, has a revolutionary innovation compared with traditional continuous asphalt mixing plant.

7. International classic control design philosophy and practice, easy to operate.

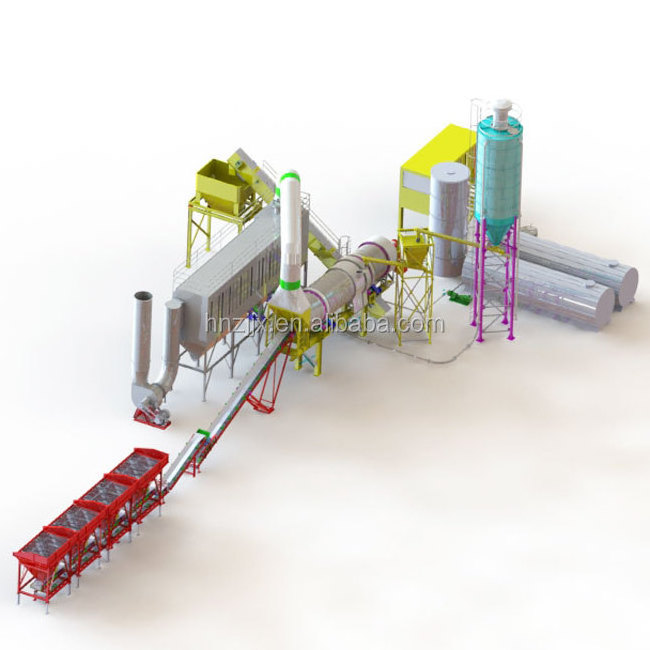

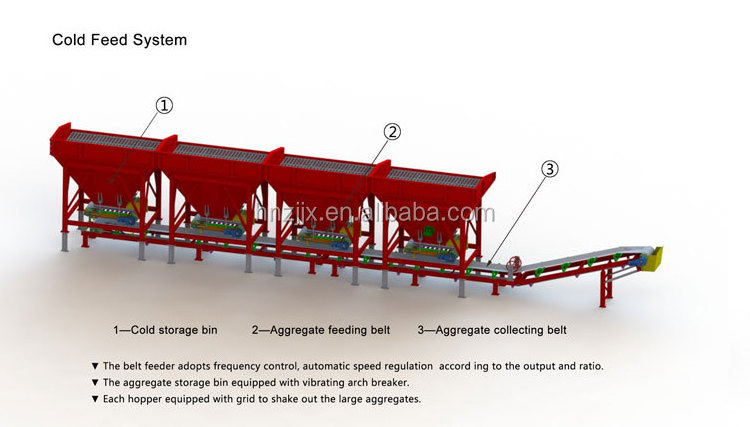

Compositions of ZAP-C(M) series continuous asphalt mixing plant:

|

Model |

ZAP-C40 |

ZAP-C60 |

ZAP-C80 |

ZAP-C120 |

Remark |

|

Rated capacity |

40T/H |

60T/H |

80T/H |

120T/H |

Standard condition |

|

Total power |

94kw |

114.65kw |

183.62kw |

244kw |

Standard configuration |

|

Cold aggregtae kinds |

4 |

4 |

4 |

4 |

|

|

Rated drying capacity |

40T/H |

60T/H |

80T/H |

120T/H |

5% moisture |

|

Fuel consumption |

≤6.5kg/t finished product |

|

|||

|

Fuel type |

Heavy/ Light oil |

Coal burner is optional |

|||

|

Control mode |

Manual/ Automatic |

|

|||

|

Finished product temperature |

140-180°C |

|

|||

|

Aggregate weighting precision |

±1% |

Continuous measurement |

|||

|

Mineral weighting precision |

±0.5% |

Continuous measurement |

|||

|

Bitumen weighting precision |

±0.3% |

Continuous measurement |

|||

|

Exhaust emission concetration |

≤50mg/Nm3 |

Bag house dust collector |

|||

Henan ZOOMLINE Machinery CO., Ltd is a professional supplier of asphalt mixing plant and support equipments that draws on years' experiences and technology developments.

Our main asphalt mixing plants include:

Stationary asphalt mixing plant(ZAP-S series)

Mobile asphalt mixing plant(ZAP-M series)

Continuous asphalt mixing plant(ZAP-C series)

ZOOMLINE is based in Nanyang Longsheng Industrial Park of Henan. To be a professional asphalt mixing plant, recycling asphalt plant, bitumen equipment supplier, we have one R & D manufacturing center which cover an area about 50,000 square meters.

The whole asphalt plant equipment is designed according to standard high cabinet container , suitable for the construction requirement in both home and abroad.

All the components of ZOOMLINE asphalt plant can be put into the container, can greatly reduce transport cost for customers .

Our asphalt mixing plant have been used in highways, high-grade highways, urban roads and airport construction and got high reputation for their excellent performance.

Pre-sale Service

We can customize project design and process design for you ( OEM service provided), produce machinery and equipment procurement plans suitable for you, and design and manufacture products according to your special needs.

Sales Service

Accompany you to complete the equipment acceptance, and assist in the preparation of construction plans and detailed procedures.

After-sale Service

All the company’s equipment provide a

one-year warranty period

.

We supply the

installation and commissioning service

and original spare parts for clients.

We guarantee to provide

technical support

to users in the whole working life of the ZOOMLINE equipment.

After sales service 7 x 24hrs Hotline:

Phone/WhatsApp/Wechat:+86-18838114766, E-mail: info(at)zoomline.biz

Q1

What payment terms are available for ZOOMLINE company?

T/T (Telegraphic Transfer), L/C(Letter of credit), BG (bank guarantee), D/P(Documents against Payment), D/A((Documents against Acceptance), Western Union and other.

Q2

How long of the delivery time?

Usually 40-80T asphalt plant needs 25-30 working days, 120-200T asphalt plant needs 35-45 working days.

Q3

How long is needed for installation working of one set asphalt mixing plant ?

20-30 working days for batch asphalt mixing plant, and 10-20 working days for continuous(drum) asphalt mixing plant.

Q4

How many person are needed for the operation of whole asphalt mixing plant ?

Six persons

Q5

How long is the service life of your asphalt mixing plant ?

Normally, the service life of our batch asphalt mixing plant is over 15 years, and it of our continuous (drum) asphalt mixing plant is over 10 years.

Q6

How about the quality guarantee period of your asphalt mixing plant ?

The guarantee period of our asphalt mixing plan is 15 months, we will bear the quality issue of all parts except wearing parts in guarantee period.

Q7

How about the spare parts supply of your company?

We will provide some wearing parts along with whole asphalt mixing plant to user freely, and user can purchase more wearing parts along with whole asphalt mixing plant. We will keep the spare parts supply to user in the whole service life of asphalt mixing plant.

Q8

How about the after sales service of your company?

We will send professional technical staff to user’s project working site to guide installing work, and commissioning the plant and training the operators of the buyer. And ZOOMLINE provide the technical support service to user’s within the whole service life of asphalt mixing plant.

Q9

How much does an asphalt plant cost?

The cost of an asphalt plant can vary widely depending on various factors such as capacity, features, location, and market conditions.

However, the asphalt plant suitable for small to medium-scale projects might cost anywhere from $50,000 to $500,000. Larger asphalt plants with higher production capacities can cost several million dollars.

Welcome to inquiry ZOOMLINE for get the best price now.

Q10

What are the three types of asphalt plants?

There are primarily three types of asphalt plants commonly used in the industry:

Batch Plants

: Batch plants produce asphalt in batches. In these plants, aggregates are proportioned and heated separately before being mixed with asphalt binder in a mixer.

Drum Plants

: Drum plants, also known as continuous plants, produce asphalt continuously. In these plants, aggregates are dried and heated in a drum while being continuously mixed with asphalt binder. The mixed asphalt is then discharged from the drum into trucks for transportation.

Batch Drum Mix Plants

: Batch drum mix plants combine features of both batch and drum plants. These plants have a drum where the drying and mixing of aggregates occur continuously, similar to drum plants.

Welcome to inquiry ZOOMLINE for get more information now.

Q11

Is it safe to live near asphalt plant?

Living near an asphalt plant can raise concerns about potential health and environmental impacts. While modern asphalt plants are designed to minimize emissions and comply with regulatory standards, there are still some potential risks associated with living in close proximity to such facilities. Here are some factors to consider , like air quality , odors , noise ,traffic and safety.

To mitigate these concerns, regulatory agencies often impose emissions limits, operating standards, and setback requirements for asphalt plants to protect public health and the environment.

Q12

How is asphalt made in a plant?

Asphalt, also known as bitumen, is produced in an asphalt plant through a process that involves heating and mixing various ingredients.

From

Aggregate Handling --- Drying and Heating --- Asphalt Binder Preparation --- Mixing --- Storage and Transport --- Quality Control ---Paving

It's worth noting that there are different types of asphalt plants, such as batch plants and drum plants, which may have variations in the production process. However, the fundamental steps involved in asphalt production remain similar across different plant types.