- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

2024 New production

-

Name:

-

soap making machine

-

Application:

-

toilet soap making machine

-

Function:

-

to make laundry soap

-

After-sales Service Provided:

-

send engineer or video guide

-

factory visit:

-

welcome

-

manual:

-

in english

-

Soap shape:

-

customzied

-

Raw Material:

-

Carbon steel

-

Voltage:

-

380V 50HZ 3 phase or customized

-

capacity:

-

100-2000kg/h

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lung Yeuk

-

Weight (KG):

-

7800

-

Marketing Type:

-

2024 New production

-

Name:

-

soap making machine

-

Application:

-

toilet soap making machine

-

Function:

-

to make laundry soap

-

After-sales Service Provided:

-

send engineer or video guide

-

factory visit:

-

welcome

-

manual:

-

in english

-

Soap shape:

-

customzied

-

Raw Material:

-

Carbon steel

-

Voltage:

-

380V 50HZ 3 phase or customized

-

capacity:

-

100-2000kg/h

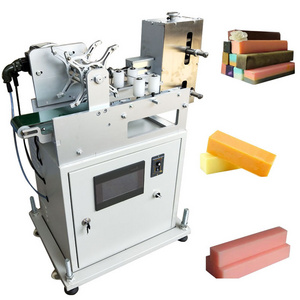

Automatic Small Mini Toilet Laundry Bar Soap Production Making Machine

This production line is a soap making machine with soap particles as raw material an output of 100-200 kg/h. After raw material mixing, grinding, vacuum stripping, electronic rolle printing and cutting/Auto Stamping machine.high-grade soap with a fatty acid content of 35-70 can be produced. The production line adopts a double-layer vacuum ejector, which can make th soap structure compact and difficult to crack.

Intruduction of Soap Making Machine

Intruduction of Soap Making Machine

This soap making machine regard soap noodles as raw materials or palm oil .The production starts with mixing soap noodles or palm oil . Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made. The soap thin sheet then converted into desired long strip soap by the plodder machine.Then the long strip soap are cut into the soap bars required size by cutting machine(there are two kinds of cutting machine.One is mechanical.The other is automatic).Finally, the soap bars gets packed by packing machine if needed.

Description of Soap Making Machine

a. This system can continuously produce laundry soap, compound soap, industrial soap and others;

b. The production line is mainly consisting of oil refining, saponification, vacuum drying and extrusion;

c. Only when the crystal form of soap is tiny, the soap become fine and smooth. The vacuum drying system can make the soap to form tiny and compact crystal texture which is mainly in the shape of β base;

d. When you produce fatty acid products( laundry soap, compound soap and industrial soap), the fatty acid content is usually 49%, the vacuum degree of the system is about of 740 mmHg, the temperature of soap base is 85 0C, vacuum dewatering is about 4%, you can take 53% fatty acid.

Material needed of Soap Making Machine

Oil or fat of plant or animal (palm oil, coconut oil, tallow oil, etc.), caustic soda (NaOH), sodium-chloride (NaCl), sodium

silicate, pigment, etc.

Production process of Soap Making Machine

Mix and melt oil --> Saponification --> Vacuum drying --> Soap noodle --> Grinding --> Vacuum Plodder (extruding) --> Cutting.

Main Machines involved for Soap Making Machine

| No | Name | Quantity | Specification |

| 1 | 600 mixer | 1 |

Function: The raw materials for producing soap and transparent soap are fully and uniformly stirred and mixed to make the granulation refined, and various auxiliary materials, additives and flavors are completely mixed into the granulation to meet the formulation requirements.

Equipment Name: Mixer (Model 600) Production: 75kg / each time Motor power: 2.2 kW / hour Dimensions: 1400*830*1050mm Weight: 252kg |

| 2 | S150 three-roll mill | 1 |

Function : The three-roll mill is mainly used to mix and grind granular blue bubbles, soaps and other raw materials at normal temperature. This machine squeezes each other with three side-by-side rollers in the horizontal direction, and the friction of different speeds achieves the grinding effect. If the general material needs to be more delicate, it needs to be ground 2 to 3 times, and the grinding fineness can reach 3-18μm.

Equipment name: Three-rod grinder (S150 type) Roller diameter: 150mm Length of working surface: 300mm Motor power: 2.2kw Dimensions: 820*800*920mm Weight: 500kg |

| 3 | C180 double vacuum delivery machine | 1 |

Equipment Name: Double Vacuum Slitting Machine

Production capacity: 100-300 kg / hour Motor power: 5.5 kW, 7.5 kW speed Dimensions: 3500*950*2300mm Weight: 1870 kg |

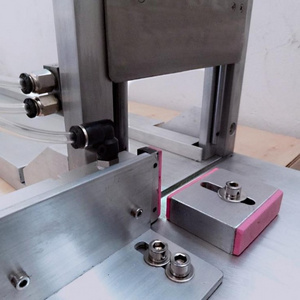

| 4 | Electronic dicer | 1 |

Cutting speed: The cutting speed is determined by the speed of the delivery machine.

Production: 500-1000kg/hour Cutting strip size: 60-400mm Dimensions: 800*360*800mm Weight: 58kg |

| 5 | Two-stage rotary vane vacuum pump | 1 |

Pumping capacity: 8 liters / second

Motor power: 1.5kw Dimensions: 51*31*39mm |

| 6 | conveyor | 3 |

Delivery to (2 meters 4 meters 4 meters)

Motor power: 1.5kw Dimensions: 4500 × 600 × 600mm |

| 7 | Electricity control box | 1 |

Equipment Name: Power Distribution Cabinet

Used to control each machine of the production line. |

Production conditions:

Production conditions:

1. Water: 1 cubic cycle of water (not consumed);

2. Electricity: 50 kW / hour, 380 volts, 50 Hz;

3. Workshop requirements: 22 meters long, 8 meters wide and 3.5 meters high (including the workers' operating area);

4. Manual requirements: 6-8 people/class.

1.Ask:What is your machine guarantee?

Ans:Usually our machine guarantee is 1 years, and we will keep contact with our customers for after-sale servise, we aim to produce better machines and make our customers satisfied.

2.Ask:What's the machine voltage or power of your machine?

Ans:Usually in our country voltage is 220v,50hz, single phase , or 380v, 50hz, 3 phase, if you have special requirement , pls tell us, we will vetify the voltage according to your requirement.

3.Ask:How to install the machine for us?

Ans:We can instuct the machine install by vedio, email ,picture, etc, and if for large project , we can also arrange our workers help you to install it in your country .

4.Ask: If we have problems when we use your machine, what should we do?

Ans: If you have any problems, just contact us, we will help you to solve, and if necesary, we will arrange our engineers to help you in your place.