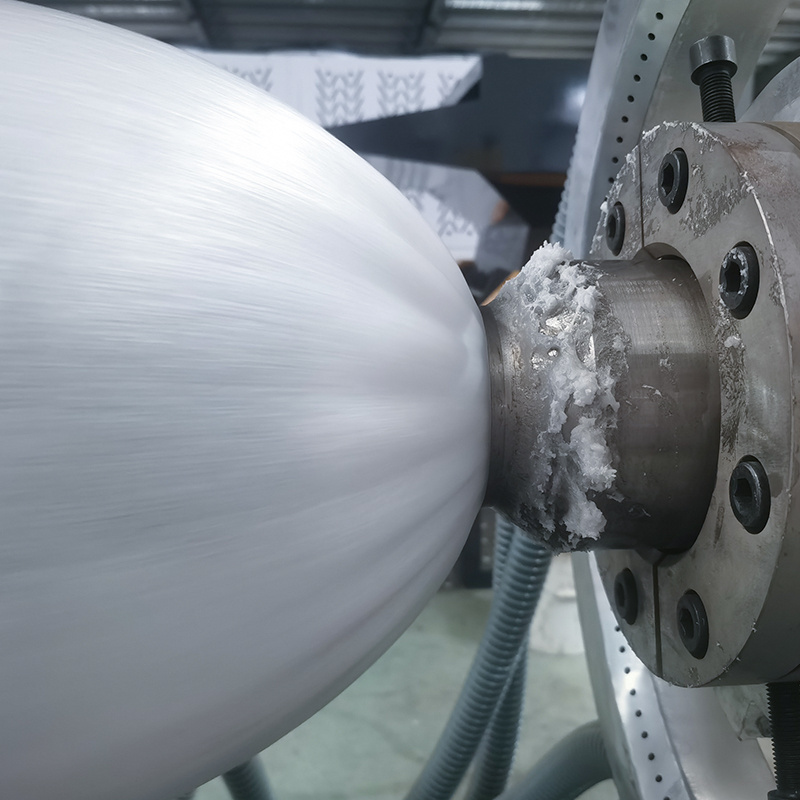

Special Neck :Cooling water jack,prevent material sticking at the inlet of hopper when material injecting.

Screw And Barrel: 38CrMoAlA nitrogen treatment.

Method of heating:cast aluminum heater

Method of cooling: inner and outer water coooling pipe.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Demeng

-

Voltage:

-

380V, 380V

-

Dimension(L*W*H):

-

3200*2800*2800mm, 23000*2300*2200

-

Power (kW):

-

170, 105

-

Weight:

-

9 KG

-

Processing Type:

-

Foaming Machine

-

Machine Type:

-

extruder

-

Weight (KG):

-

7000 KG

-

Foaming times:

-

16-47

-

Width:

-

1000-1800mm

-

Thickness:

-

0.3-6.5

-

Screw L:D:

-

55:1

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

55:1

-

Screw Speed (rpm):

-

45 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Demeng

-

Voltage:

-

380V, 380V

-

Dimension(L*W*H):

-

3200*2800*2800mm, 23000*2300*2200

-

Power (kW):

-

170, 105

-

Weight:

-

9 KG

-

Processing Type:

-

Foaming Machine

-

Machine Type:

-

extruder

-

Weight (KG):

-

7000 KG

-

Foaming times:

-

16-47

-

Width:

-

1000-1800mm

-

Thickness:

-

0.3-6.5

-

Screw L:D:

-

55:1

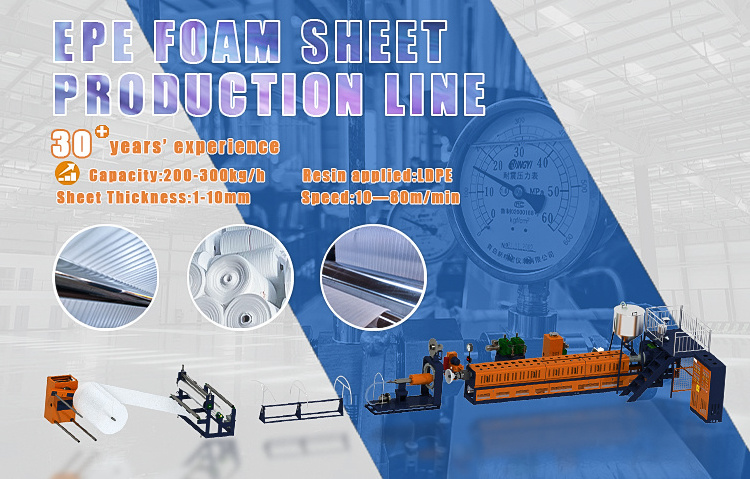

Machine introduction

EPE foam sheet production line

Polyethylene foam sheet(film), also named as pearl cotton,is a kindof new-type packing material with the features of dampproof,shockproof,sound insolation,heat preservation and good plasticity.It is an ideal substitute of traditional packing materials and used widely in the packing of electronic product, commodity, glass, pottery, electrical household appliances,spraying, furniture, hardware product,toy,etc.

Equipment Specifications

|

Model

|

Unit

|

EPE90

|

EPE105

|

EPE120

|

EPE150

|

EPE170

|

EPE180

|

EPE200

|

EPE220

|

|||||||

|

Screw diameter

L/D

|

|

90

/55:1

|

105

/55:1

|

120

/55:1

|

150

/55:1

|

170

/55:1

|

180

/55:1

|

200

/55:1

|

220

/55:1

|

|||||||

|

Screw speed

|

r/min

|

5-45

|

5-45

|

5-45

|

5-45

|

5-45

|

5-45

|

5-45

|

5-45

|

|||||||

|

Foam rate

|

|

20-40

|

20-40

|

20-40

|

20-40

|

20-40

|

20-48

|

20-48

|

20-48

|

|||||||

|

Width of product

|

mm

|

1000-1400

|

1000-1500

|

1000-2000

|

1000-2000

|

1000-2000

|

1000-2000

|

1000-2000

|

1000-2000

|

|||||||

|

Thickness of product

|

mm

|

0.5-4.5

|

0.5-6.5

|

0.8-8

|

1-12

|

2-16

|

2-18

|

3-20

|

4-25

|

|||||||

|

Cooling method

|

|

cooled by water

|

|

|

|

|

|

|

|

|||||||

|

total power

|

kw

|

110

|

130

|

170

|

240

|

285

|

320

|

350

|

420

|

|||||||

|

Device length

|

mm

|

22000

|

23000

|

25000

|

30000

|

32000

|

34000

|

38000

|

45000

|

|||||||

|

Equipment width

|

mm

|

2300

|

2300

|

2300

|

2300

|

2300

|

2800

|

2800

|

2800

|

|||||||

|

Equipment high

|

mm

|

2200

|

2200

|

2200

|

2200

|

2200

|

3500

|

3800

|

3800

|

|||||||

|

Total weight

(approx)

|

kg

|

8500

|

9000

|

12000

|

15000

|

17000

|

17500

|

18000

|

22000

|

|||||||

Equipment details

Main Extruder

Gear Box And Automatic Feeder

1. The driving seystme adopts well-known brands: GUOMAO gear box and Simense motor

2. The whole body of automatic feeding hopper is be made from stainless steel #304.

3. Water recycling system:Stainless steel connection

Talcumpowder injection unit

Adopts Italy technology. Double screw substitute single screw, Solve the poor mobility features of talcum powder.The motor is controlled by inverter to make talcum powder injection accurate and stable.

Stainless steel #304 hopper with sight-glass

The feeding frame is assembled with stainless steel #304.

Full automatic control feeding device

Screen Changer

Brand: JCTIME, top brand in China

Mode: double station, nostop changing filter screen

Die Mold Head

Die lip Material:carbon alloy steel

Body Material:carbon alloy steel

the thickness control of sheet: regulated by the distance between mold heads

Winding Unit

Model: Double axis cantilever displacement t

ype(air shaft type)

Maximum of rolling weight: Maximum 30kg×1m (diameter)

Haul-off unit

Install static electricity eliminator under haul-off unit (ion fan). The black one

Material of expanding roller: stainless steel

Material: STPG tube hard chrome plating

Material: STPG tube hard chrome plating

epe polyethylene foamed fruit mesh net bag packing machine

EPE foam net is a kind of new soft packing material. It is widely used for the package of glass products, precision, instrument,and various kinds of fruits. Plastic epe foam packing net extrusion production line for fruit mainly used the production of EPE sheet material, after thawing the LDPE resin mixed with butane gas, talcum powder, anti-shrinkage agents and other agents through the extruder and foaming from the die and die lip, then after setting ring fixed to the sheet size, the final product take-up by the roller.

|

Total powe

|

50 kw

|

|

Main motor

|

15KW

|

|

Cooling water

|

80L/H

|

|

Speed of the manufacture line

|

10—60m/min

|

Model: rotating gear die

1.Die Head size: 2 sets (customer decided size)

2.Material: carbon alloy steel

3.Heating area: 1 pc

4.Heating method: heater

5.Blower: 180W×2 pcs

6.Die motor: 3KW

7.Inverter control motor

1.Die Head size: 2 sets (customer decided size)

2.Material: carbon alloy steel

3.Heating area: 1 pc

4.Heating method: heater

5.Blower: 180W×2 pcs

6.Die motor: 3KW

7.Inverter control motor

Model: rotary knife type

Haul-0ff motor (adjustable):0.75KW

Cutting motor (adjustable):0.75KW

Haul-off and cutting driven type: motor drives gear box, controlled by inverter.

Count control: meter controller can be preset alarming

Haul-0ff motor (adjustable):0.75KW

Cutting motor (adjustable):0.75KW

Haul-off and cutting driven type: motor drives gear box, controlled by inverter.

Count control: meter controller can be preset alarming

It adopts Italy technology. Double screw substitute single screw, Solve the poor mobility features of talcum powder.

The motor is controlled by inverter to make talcum powder injection accurate and stable

Anti-shrinking agent: glycerin monostearate(GMS)

1.Metering pump style: high pressure measure pump, single pillar pistonMethod of heating: belt heater

2.Heating zone: 2 zones

3.Detector: 2 detecting point

1.Metering pump style: high pressure measure pump, single pillar pistonMethod of heating: belt heater

2.Heating zone: 2 zones

3.Detector: 2 detecting point

With Explosion-proof motors

Recommended Product

Packaging & delivery

Customer photo

FAQ

Q: Why are many pictures on the Internet the same as your company?

A: Because our company has been specialized in plastic machinery for more than 30 years, after years of exploration and continuous research, the appearance of the equipment and the ease of use has led the Chinese plastic machinery industry, it is inevitable to be stolen by competitors, but our core technology is not something that everyone can learn.

Q: Why did I choose your company?

A: a) We are the Leading foam machine Manufacturer in China.

b) We have made foam machine for about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have a professional technical team, supply 24 hours service.

A: Because our company has been specialized in plastic machinery for more than 30 years, after years of exploration and continuous research, the appearance of the equipment and the ease of use has led the Chinese plastic machinery industry, it is inevitable to be stolen by competitors, but our core technology is not something that everyone can learn.

Q: Why did I choose your company?

A: a) We are the Leading foam machine Manufacturer in China.

b) We have made foam machine for about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have a professional technical team, supply 24 hours service.

Q: What is EPE foam material and its applications?

A: EPE foam is a soft material made of foamed polyethylene, widely used for cushioning and protection in packaging and transportation.

Q: How to operate EPE foam machine?

A: Add polyethylene particles to the machine's hopper, start the machine, and control foaming, cooling, cutting through the control system to produce foam products.

Q: What are the types and specifications of EPE foam machines?

A: Different types are available to meet different production needs.

Q: Does EPE foam machine need maintenance?

A: Yes, regular maintenance is needed for normal operation and longer lifespan.

Q: What is the price range of EPE foam machine?

A: The price varies depending on machine model, specification, production capacity, and configuration. Customers can choose according to their needs and budget.

A: EPE foam is a soft material made of foamed polyethylene, widely used for cushioning and protection in packaging and transportation.

Q: How to operate EPE foam machine?

A: Add polyethylene particles to the machine's hopper, start the machine, and control foaming, cooling, cutting through the control system to produce foam products.

Q: What are the types and specifications of EPE foam machines?

A: Different types are available to meet different production needs.

Q: Does EPE foam machine need maintenance?

A: Yes, regular maintenance is needed for normal operation and longer lifespan.

Q: What is the price range of EPE foam machine?

A: The price varies depending on machine model, specification, production capacity, and configuration. Customers can choose according to their needs and budget.

Hot Searches