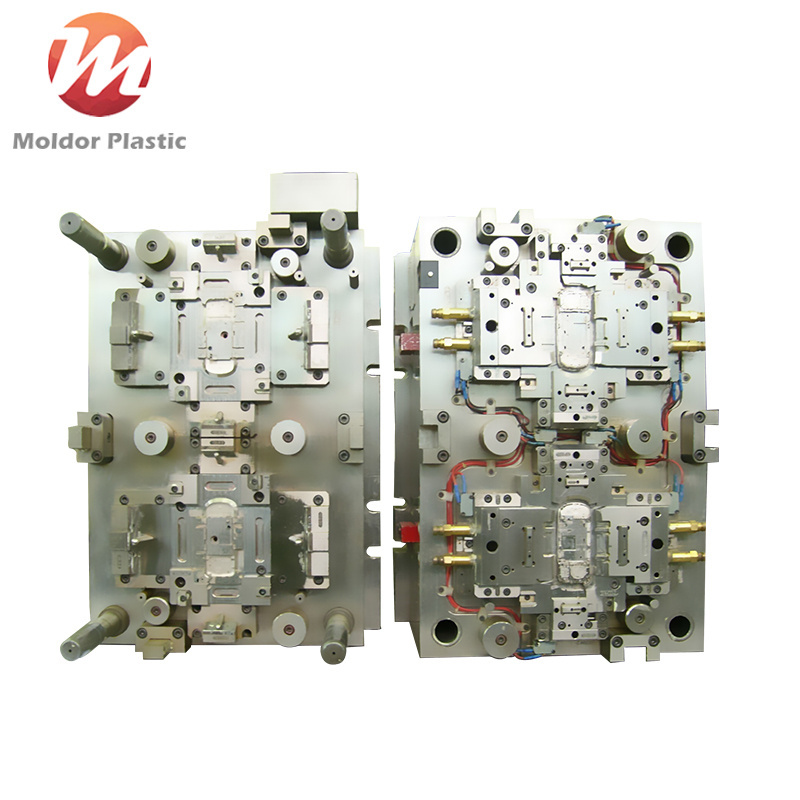

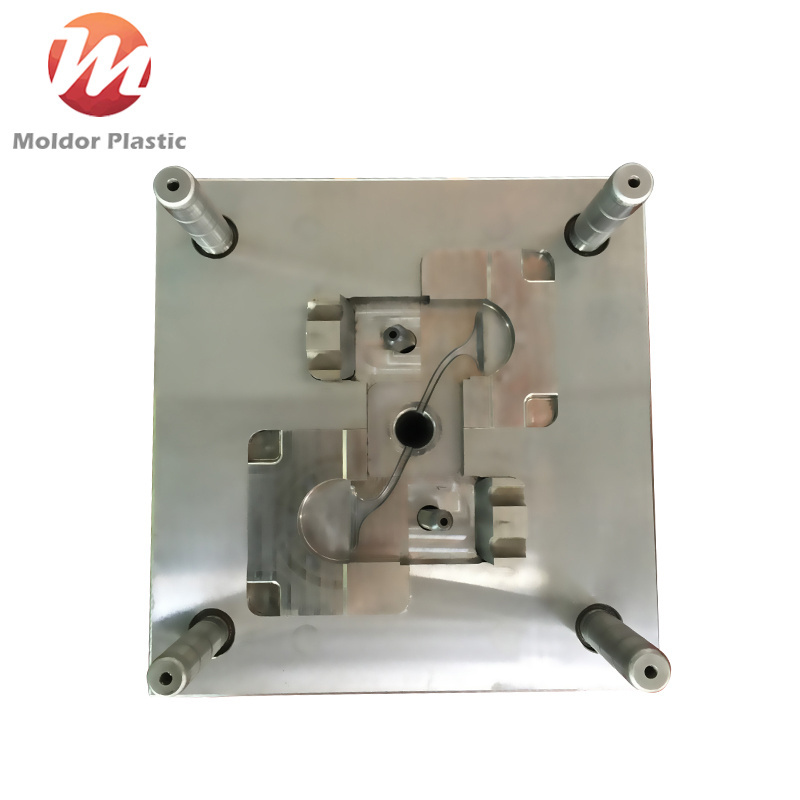

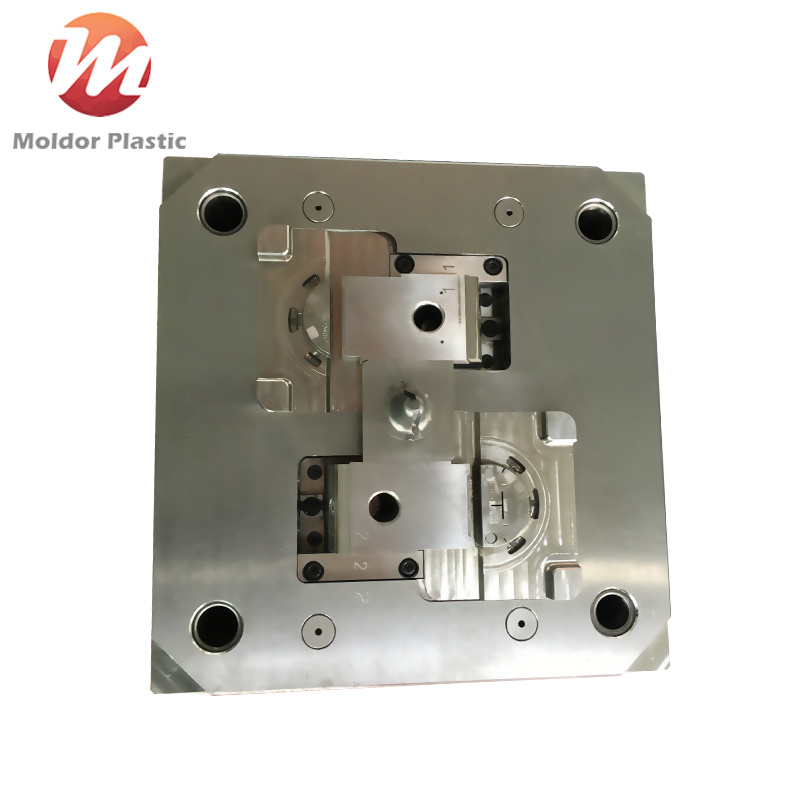

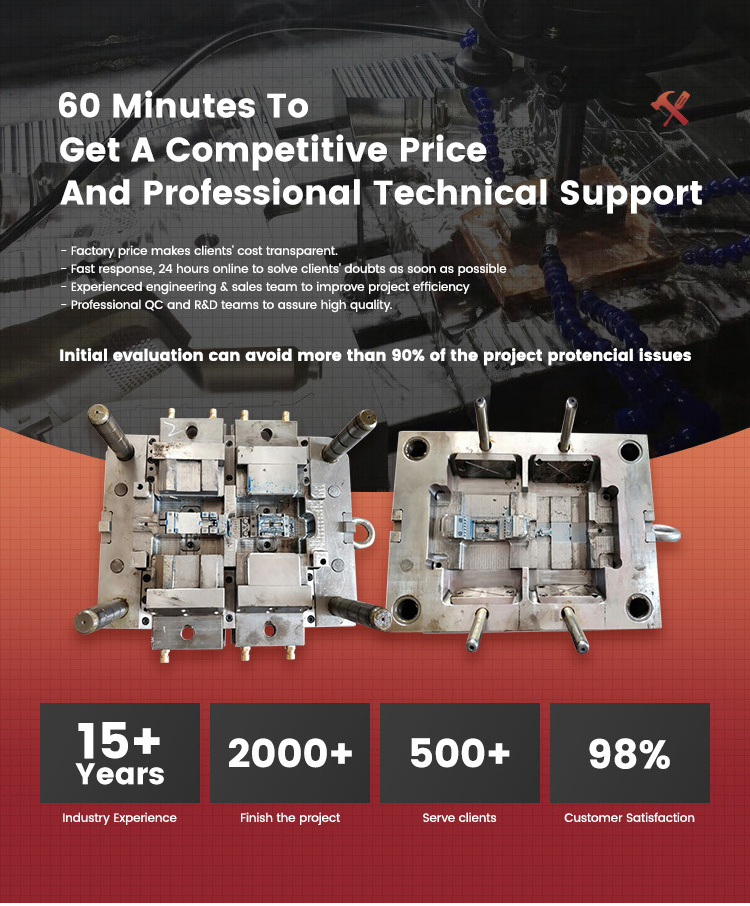

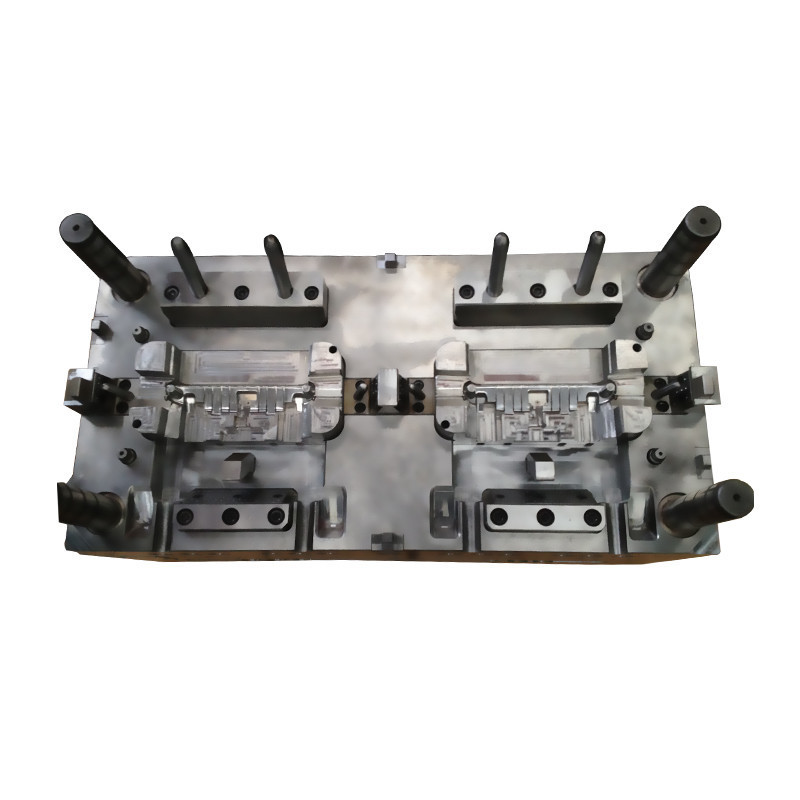

1. In-house mold design and building capabilities to

improve work efficiency.

2. NDA agreement can be signed to protect customers'

idea and design.

3. Professional sales team. Good communication skills

and after service.

4. Professional design team, mold maker engineer.

OEM/ODM service.

5. Professional QC and R&D teams to assure high quality.

6. In time response to letters and emails.

7. On time delivery.

......