- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

6

-

Weight (KG):

-

500

-

Machine name:

-

Machine name

-

Model:

-

V-DB300

-

Motor:

-

6KW

-

Voltage:

-

380v60hz 3phase

-

Input rotary speed:

-

16rpm/min

-

Blades details and rigidity:

-

180*12 / 9CrSi

-

Blades quantity:

-

24 pieces

-

feeding hole size:

-

500*500mm

-

Machine size:

-

1420*570*1429mm

-

Machine weight:

-

500KG

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

VANEST

-

Power (kW):

-

6

-

Weight (KG):

-

500

-

Machine name:

-

Machine name

-

Model:

-

V-DB300

-

Motor:

-

6KW

-

Voltage:

-

380v60hz 3phase

-

Input rotary speed:

-

16rpm/min

-

Blades details and rigidity:

-

180*12 / 9CrSi

-

Blades quantity:

-

24 pieces

-

feeding hole size:

-

500*500mm

-

Machine size:

-

1420*570*1429mm

-

Machine weight:

-

500KG

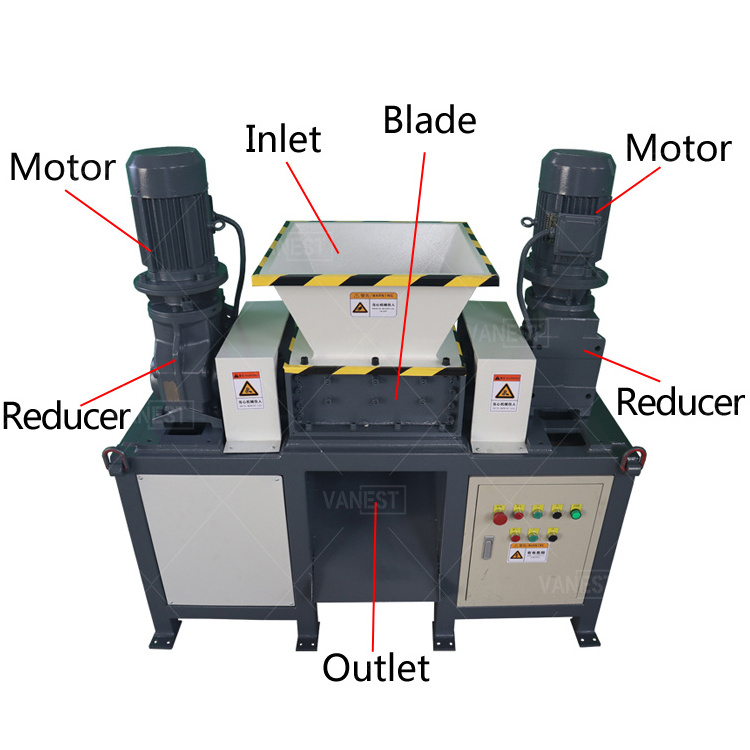

Small Double Shaft Shredder Machine

|

Model

|

V-DB300

|

V-DB400

|

V-DB500

|

V-DBK600 with PLC

|

V-DBK800 with PLC

|

|

Motor

|

3KW

|

4KW

|

7.5KW (2 units)

|

11KW (2 units)

|

22KW (2 units)

|

|

Voltage

|

380v 50hz 3phase

|

380v 50hz 3phase

|

380v 50hz 3phase

|

380v 50hz 3phase

|

380v 50hz 3phase

|

|

Reduction box

|

JL2#-16

|

JL3#-15

|

JL4#-15 (2 units)

|

K107 (2 units)

|

K127 (2 units)

|

|

Input rotary speed

|

16rpm/min

|

15rpm/min

|

15rpm/min

|

16rpm/min

|

16rpm/min

|

|

Max input torque

|

3200Nm

|

5800Nm

|

9148Nm

|

25000Nm

|

25000Nm

|

|

Input axis diameter

|

Φ50

|

Φ50

|

Φ70

|

Φ140

|

Φ140

|

|

Blades details and rigidity

|

Φ180*12 / 9CrSi

|

Φ180*15 / 9CrSi

|

Φ200*20 / 9CrSi

|

Φ250*20 / 9CrSi

|

Φ300*20 / 9CrSi

|

|

Blades quantity

|

24 pieces

|

26 pieces

|

24 pieces

|

29 pieces

|

26 pieces

|

|

Feeding hole size

|

500*500mm

|

600*500*300mm

|

700*600*300mm

|

1000*800*500mm

|

1500*1000*600mm

|

|

Shredder size

|

300mm

|

480mm

|

570mm

|

550mm

|

800mm

|

|

Shredder height

|

200mm

|

200mm

|

200mm

|

720mm

|

1000mm

|

|

Machine size(L*W*H)

|

1420*570*1429mm

|

154*600*1450mm

|

1840*700*1600mm

|

1860*920*1800mm

|

2280*1160*2220mm

|

|

Machine weight

|

500KG

|

800KG

|

1000KG

|

2800KG

|

4500KG

|

Product Application

High quality waste shredder/plastic crusher machine is used to shred the woods, building templates, old furniture, timbers,plastics, rubbers, fibers, paper, batteries, large-scale hollow materials (plastic and other large container), and a variety of mixed wastes (especially wastes containing metal or sediment, such as: roll film, woven bag, TV set, refrigerator shells, car and medium car tires and hollow barrels, fishing nets, cardboard, circuit boards, etc. )

* The materials can be processed by shredder machine.(Difference models used for difference materials. Before order please contact

our seller with your raw materials.)

Working principle

Working principle of double shaft shredder:

The double-shaft shredder is sheared by the blades on the two shafts to meet the requirements of shredding materials.

The size after shredding is related to the thickness of the shredding blade and the number of teeth.

The thinner the blade, the smaller the size of the shredded material, the more the number of cutter teeth, the shorter the length of the shredded material.

VANEST Shredding machine product advantages:

1. The blade holder and blade on the rotor can be disassembled for easy cleaning and maintenance;

2. Each moving knife has 4 cutting edges, which can be rotated 90° after wear to continue to use;

3. The main shaft is driven by the gear reduction box, running smoothly, low noise, large torque;

4. Adopt PLC program control system, can automatically reverse, make the machine run stably;

5. The box body is welded and tempered after welding to eliminate the welding stress;

6. The installation position of moving knife is precisely machined by machining center to ensure that the clearance between each moving knife and fixed knife is the same;

7. The moving tool holder is embedded in the tool shaft with high strength screws. On, can prevent welding type after long-term vibration caused by the phenomenon of knife drop.

8. Convenient transportation after tearing, can reduce transportation cost, increase transportation efficiency, convenient secondary processing.

Hot Searches