- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1022*978*481mm

-

Year:

-

new

-

Operating temperature range:

-

-10~43°C

-

Drying temperature range:

-

30~75°C

-

Compressor form:

-

High temperature enthalpy fully enclosed vortex

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yimu

-

Weight:

-

500 KG, 500-800kg

-

Dimension(L*W*H):

-

1022*978*481mm

-

Year:

-

new

-

Operating temperature range:

-

-10~43°C

-

Drying temperature range:

-

30~75°C

-

Compressor form:

-

High temperature enthalpy fully enclosed vortex

Product information

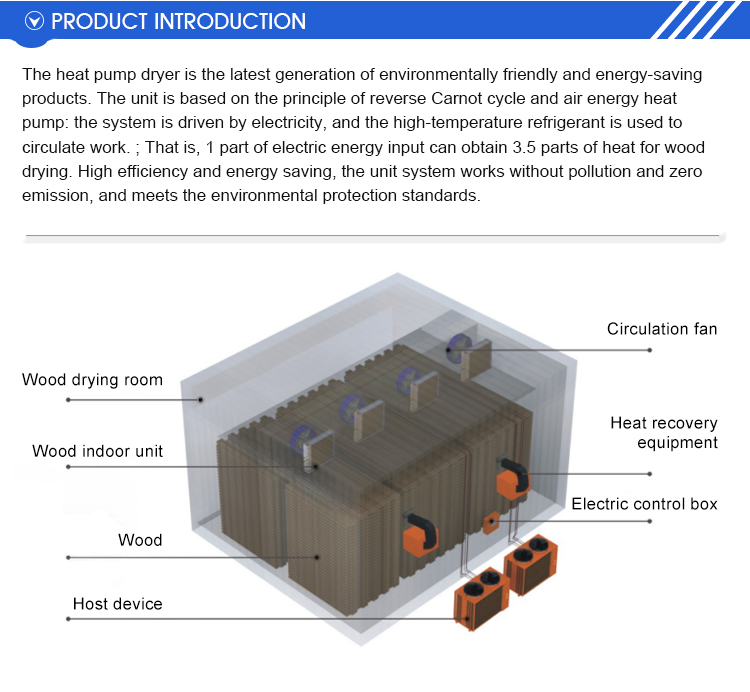

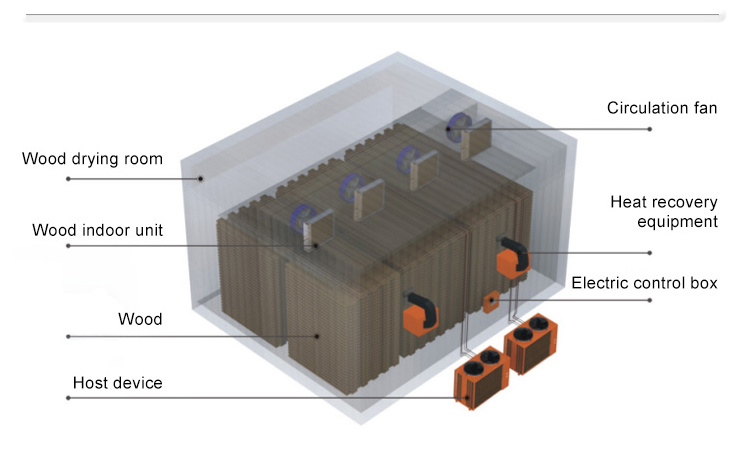

The heat pump dryer is the latest generation of environmentally friendly and energy-saving products. The unit is based on the principle of reverse Carnot cycle and air energy heat pump: the system is driven by electricity, and the high-temperature refrigerant is used to circulate work. ; That is, 1 part of electric energy input can obtain 3.5 parts of heat for wood drying. High efficiency and energy saving, the unit system works without pollution and zero emission, and meets the environmental protection standards.

Specification

|

Scope of application

|

Drying type

|

|

|

Low temperature circulating air supply

|

|

|||

|

|

Operating temperature range

|

|

|

-10~43°C

|

|

|||

|

|

Drying temperature range

|

|

|

30~75°C

|

|

|||

|

The outdoor unit

|

Unit Type

|

AHRW

|

070S-U-Z

|

140S-U-Z

|

200S-U-Z

|

|||

|

|

Rated Calories

|

kW

|

22.0

|

43

|

62

|

|||

|

|

Input power

|

kW

|

6.5

|

13

|

19.8

|

|||

|

|

Running current

|

A

|

11.2

|

22.4

|

33.7

|

|||

|

|

Power form

|

V/Ph/Hz

|

380/3/50

|

|

|

|||

|

|

Compressor form

|

/

|

High temperature enthalpy fully enclosed vortex

|

|

|

|||

|

|

Drying room temperature control accuracy

|

℃

|

±1

|

|

|

|||

|

|

Number of compressors

|

tower

|

1

|

2

|

2

|

|||

|

|

Liquid pipe, gas pipe size

|

inch

|

1/2,3/4

|

1/2*2,3/4*2

|

3/4*2,3/4*4

|

|||

|

|

refrigerant

|

/

|

R134a

|

|

|

|||

|

|

Dimensions (L/W/H)

|

mm

|

720*720*1000

|

1420*720*1070

|

1620*920*1070

|

|||

|

|

Net weight/gross weight

|

kg

|

140

|

235

|

355

|

|||

|

Indoor unit

|

Unit Type

|

AHRG

|

070S-DM

|

070S-DM*2

|

100S-DM*2

|

|||

|

|

Liquid pipe, gas pipe size

|

inch

|

1/2,3/4

|

1/2*2,3/4*2

|

3/4*2,3/4*4

|

|||

|

|

Total fan power

|

KW

|

0.75

|

2.2

|

2.2

|

|||

|

|

Rated air volume

|

m3/h

|

7500

|

15000

|

15000

|

|||

|

|

Supply air static pressure

|

Pa

|

80

|

120

|

120

|

|||

|

|

Electric heating power

|

kw

|

6

|

6*2

|

12*2

|

|||

|

|

Dimensions (L/W/H)

|

mm

|

1265*450*950

|

1265*450*950*2

|

1800*450*950

|

|||

|

|

Net weight/gross weight

|

kg

|

45

|

45*2

|

80*2

|

|||

|

Heat recovery machine

|

Unit Type

|

ABR

|

200S

|

|

|

|||

|

|

Total fan power

|

kW

|

0.5

|

|

|

|||

|

|

Rated air volume

|

m3/h

|

2000

|

|

|

|||

|

|

Moisture removal

|

kg/h

|

40

|

|

|

|||

|

|

Dimensions (L/W/H)

|

mm

|

1022*978*481

|

|

|

|||

|

|

Net weight

|

kg

|

63

|

|

|

|||

Product details

International famous brand jet enthalpy increasing scroll compressor

Two-stage compression technology,ultra-low temperature operation of the world's top brand compressors,power Pengpai large heating capacity,strong resistance to liquid shock,stable and reliable.

Intelligent control system to create "smart core"

It adopts 7-inch industrial LCD screen for automatic control and convenient operation, different drying curves can be set to meet the drying of different materials,and it has a power-off memory function,one-key setting and intelligent management is easily realized;equipped with high-precision temperature and humidity sensors,response Fast,long-distance transmission,strong anti-interference ability eliminating post-maintenance work.

International famous brand electronic expansion valve

The well-known international famous brand electronic expansion valve is used to intelligently adjust the liquid supply volume of the evaporator,which is suitable for low temperature,energy saving and low power consumption,and is durable.

Enlarged evaporator heat exchange leads the industry by20%

The finned heat exchanger determines the level of system energy efficiency.Aubert Air can combine years of R&D and production

experience to optimize the system design and match the enlarged corrugated aluminum foil fin evaporator to increase the thermal capacity by more than 20%.

*Multiple coatings ensure efficient heat exchange of fins and longer service life.

"The host perfectly matches the fin area,greatly improving the heat exchange efficiency.

*The solder joints of the integrated heat exchanger are greatly reduced,and the outdoor unit runs more stably.

*Corrugated fins increase turbulence and increase heat exchange efficiency by more than 20%.

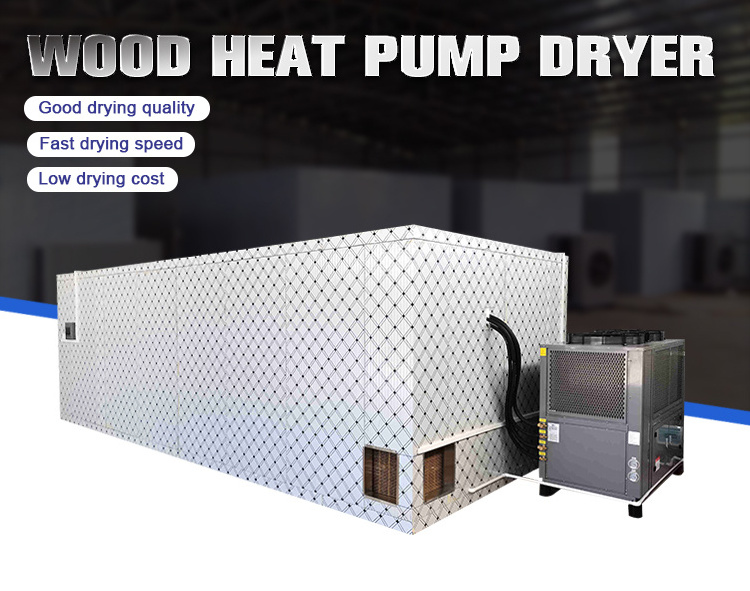

Product features

Environmental friendly

No pollution and zero emission, in line with national environmental protection requirements.

Quality

Intelligent control, good quality and high yield.

Energy saving

Energy efficiency up to 350%, saving costs.

Durable

Using anti-corrosion material, the life span is more than 10 years.

Simple

Simple installation, no need for special equipment verification.

Intelligent

Pre-made curves allow you to easily handle wood drying.

Product application

The wood-specific drying unit can be applied to all furniture and wood balance health preservation, wood intelligent drying, wood veneer drying, wood secondary drying, etc.; it can realize low-cost operation of wood drying, one key to complete the whole process of automatic humidification and drying, the drying cycle of finished products is short, the yield of finished products is high, and the drying process is pollution-free.

There are many types of wood, commonly used wood are:

Product comparison

Hot Searches