Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Building,Construction,Deaoration,kitchen ware,etc

-

Thickness:

-

1.5-15mm 0.12-2.0mm 0.3-3.0mm, 0.3-3.0mm/1.5-15mm

-

Width:

-

1000 1220 1500 1800 2000mm, 1000-2000mm

-

Grade:

-

200 Series,300 Series, 400 Series

-

Product name:

-

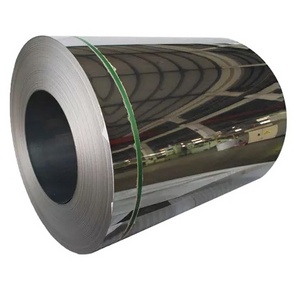

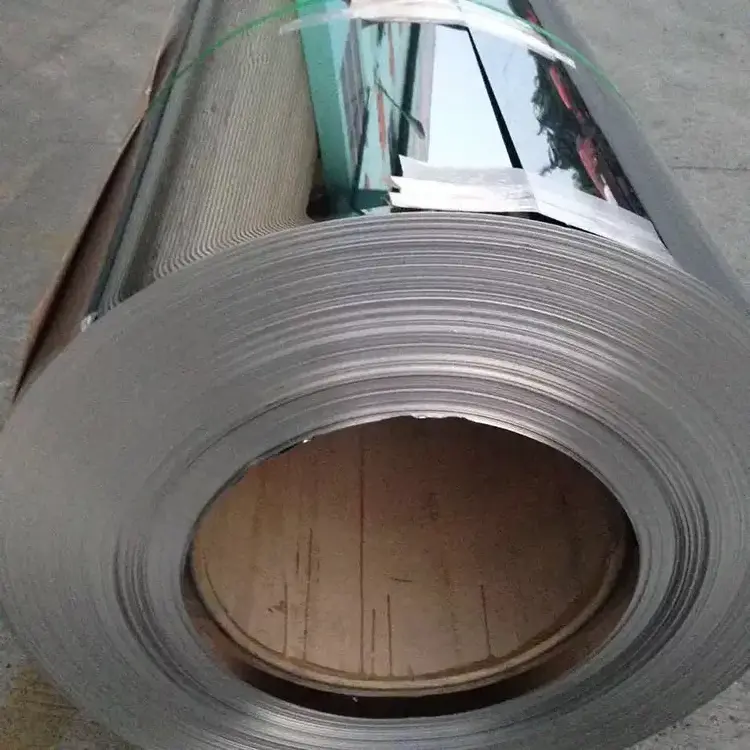

Stainless Steel Coil

-

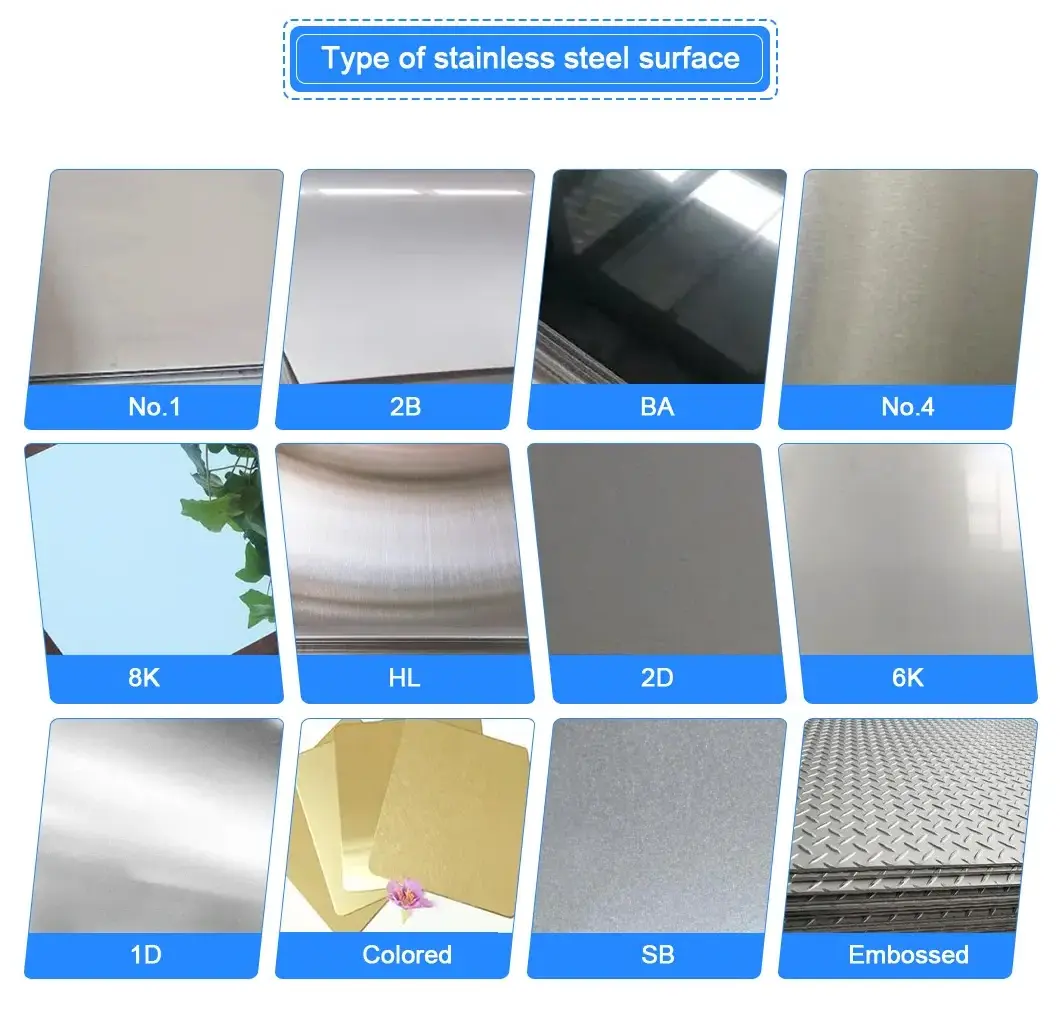

Surface:

-

BA,2B,NO.1,NO.4,8K,HL,Mirror Finish

-

Packing:

-

PVC Film+Waterproof Paper+Fumigation Wooden Frame

-

Sample:

-

Avaliable

-

Material:

-

200 Series/300 Series/400series/copper

-

Edge:

-

Mill Edge &Slit Edge

-

Level:

-

2B 8K BA HL

Quick Details

-

Surface Finish:

-

2B

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

Sinosteel

-

Application:

-

Building,Construction,Deaoration,kitchen ware,etc

-

Thickness:

-

1.5-15mm 0.12-2.0mm 0.3-3.0mm, 0.3-3.0mm/1.5-15mm

-

Width:

-

1000 1220 1500 1800 2000mm, 1000-2000mm

-

Grade:

-

200 Series,300 Series, 400 Series

-

Product name:

-

Stainless Steel Coil

-

Surface:

-

BA,2B,NO.1,NO.4,8K,HL,Mirror Finish

-

Packing:

-

PVC Film+Waterproof Paper+Fumigation Wooden Frame

-

Sample:

-

Avaliable

-

Material:

-

200 Series/300 Series/400series/copper

-

Edge:

-

Mill Edge &Slit Edge

-

Level:

-

2B 8K BA HL

Products Description

What is a stainless steel coil?

Stainless steel is initially produced in slabs, which are then put through a conversion process using a Z mill, which converts the slab into coil prior to further rolling. These wide coils are typically made at around 1250mm (sometimes a little wider) and are known as 'mill edge coils'.

Cold-rolled steel coils.

Cold-rolled steel is a more finished product that not only looks nicer, having a more finished surface but is also more durable than is hot-rolled steel. This steel is created by further processing hot-rolled steel. Cold-rolled steel is superior in

performance compared to hot-rolled steel but may be harder to manipulate than hot-rolled steel due to a higher carbon content.

Stainless steel is initially produced in slabs, which are then put through a conversion process using a Z mill, which converts the slab into coil prior to further rolling. These wide coils are typically made at around 1250mm (sometimes a little wider) and are known as 'mill edge coils'.

Cold-rolled steel coils.

Cold-rolled steel is a more finished product that not only looks nicer, having a more finished surface but is also more durable than is hot-rolled steel. This steel is created by further processing hot-rolled steel. Cold-rolled steel is superior in

performance compared to hot-rolled steel but may be harder to manipulate than hot-rolled steel due to a higher carbon content.

Hot-rolled steel coils.

A hot-rolled steel coil is formed almost exactly as its name implies: the steel is rolled at a high temperature, which makes the steel easier to manipulate, resulting in a product that is easier to work with. Because there is less processing involved in the manufacturing of hot-rolled steel, it is typically much less expensive than cold-rolled steel coils.

A hot-rolled steel coil is formed almost exactly as its name implies: the steel is rolled at a high temperature, which makes the steel easier to manipulate, resulting in a product that is easier to work with. Because there is less processing involved in the manufacturing of hot-rolled steel, it is typically much less expensive than cold-rolled steel coils.

|

Material Grade

|

201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 etc

Special Stainless Steel:904L,347/347H,317/317L,316Ti,254Mo |

|

Standard

|

JIS/JIS/SUS/GB/DIN/ASTM/AISI/EN

|

|

Surface

|

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

|

|

Technique

|

Cold Rolled; Hot Rolled

|

|

Length

|

2000mm, 2438mm, 2500mm, 3000mm, 6000mm or as required

|

|

Width

|

8-3000mm

|

|

Thickness

|

Cold rolled:0.15mm-10mm

Hot rolled: 3.0mm-180mm |

|

Applicaiton

|

Escalator, Elevator, Doors

Furniture Production tools, Kitchen appliances, freezers, cold rooms Auto Parts Machinery and Packaging Equipment and Medical devices Transport system |

|

Trade Terms

|

EXW,FOB,CIF, CFR

|

|

Loading Port

|

Shanghai port, Tianjin port, Qindao port

|

|

Payment terms

|

1)TT 30 % deposit in advance and balance 70%TT before delivery.

|

|

|

2) 30% deposit by T/T, the balance by L/C at sight.

|

|

|

3) 100% L/C at sight.

|

|

MOQ

|

1 Ton

|

|

Packing Detail

|

Wooden Pallet or according to customer's requirements

|

|

Delivery time

|

1.Usually,within10-20days after receiving deposit or LC.

2.According to the order quantity |

|

Samples

|

Free samples are provided but the freight is borne by the buyer

|

|

Surface Finish

|

|

Definition

|

Application

|

|

|

2B |

|

Finished by heat treatment , picking or equipvalent cold rolling , followed by skin pass to obtain adequate luster surface.

|

With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk

containers ,tableware and so on. |

|

|

BA |

|

Bright heat treatment after cold rolling.

|

Structual members .etc.kitchen utensil ,cutlery ,eleltric applicances ,medical instruments ,building decorations ,etc.

|

|

|

NO.3/NO.4

|

|

Polished with No.150-240 abrasives.

|

Milky food processing equipment , medicalinstruments ,building decorations.

|

|

|

HL |

|

Finshed by polishing with abrasives of suitable grain size to obtain continuous streaks.

|

Building decorations ,such as elevators ,escalators ,door etc.

|

|

|

6K/8K |

|

A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with

all gritlines are removed. |

Buliding entrances,bulkding column casting ,elevator's wall doors ,coun

|

|

What is the difference between 304 and 316 stainless steel?

304 contains 18% chromium and 8% nickel while 316 contains 16% chromium, 10% nickel and 2% molybdenum.

The molybdenum is added to help resist corrosion to chlorides (like sea water and de-icing salts).

What type of stainless steel is best?

Most stainless steel ordered around the world is Grade 304.

It offers the standard corrosion resistance, formability, strength, and easy maintenance for which stainless is known.

While 316 comes in second in terms of quantities sold, it offers vastly superior corrosion resistance to chlorides and acids.

Which is stronger 304 or 316 stainless steel?

When it comes to tensile strength, the two are almost identical.

The yield strength of 316 stainless steel is higher, but the difference is relatively small.

When hardened through cold working, both 304 and 316 stainless steel can achieve considerably

higher hardness and strength ratings.

Smooth and flat surface

Strict selection of raw materials, high preci-

sion, uniform thickness, smooth surface,

high cost performance.

With international experience and profession-

alism, we can provide customers with various

high-quality steel products.

Corrosion resistance

Stainless steel plate has acid and alkali corrosion re-sistance, ,high temperature resistance ,rust resistance and long service life.

We have a large number of stainless steel plates and coils in stock,which can be customized according to your requirements.

310 stainless steel coil

is a stainless steel material containing molybdenum, which can form a passivation film in the air or in a chemically corrosive medium to isolate the metal from the outside world and protect the metallographic structure of the matrix from oxidation. 310 has excellent pitting corrosion resistance and machinability. Its face-centered cubic structure has high resistance to stress relaxation and low temperature impact toughness.

304L stainless steel coil is a general-purpose stainless steel coil material, which is widely used to make equipment and parts that require good comprehensive performance (corrosion resistance and formability). The carbon content of 304L stainless steel is lower than that of 304 stainless steel. This steel will precipitate less carbide near the weld, which can reduce intergranular corrosion, so the ability to resist intergranular corrosion is higher than that of 304 stainless steel.

316 stainless steel coils perform well at temperatures up to 800°C. 316 has excellent rust and wear resistance compared to other stainless steel grades. The addition of molybdenum to 316 stainless steel increases its resistance to acid, alkali, and chloride pitting. Ease of Forming and Welding: 316 stainless steel is easily welded by TIG or MIG welding and does not require post-weld annealing. After annealing, it is non-magnetic.

304L stainless steel coil is a general-purpose stainless steel coil material, which is widely used to make equipment and parts that require good comprehensive performance (corrosion resistance and formability). The carbon content of 304L stainless steel is lower than that of 304 stainless steel. This steel will precipitate less carbide near the weld, which can reduce intergranular corrosion, so the ability to resist intergranular corrosion is higher than that of 304 stainless steel.

316 stainless steel coils perform well at temperatures up to 800°C. 316 has excellent rust and wear resistance compared to other stainless steel grades. The addition of molybdenum to 316 stainless steel increases its resistance to acid, alkali, and chloride pitting. Ease of Forming and Welding: 316 stainless steel is easily welded by TIG or MIG welding and does not require post-weld annealing. After annealing, it is non-magnetic.

Application case

Recommend Products

Hot Searches