- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

more than 229HB

-

Heat treatment:

-

Anneal,quenching ,tempering

-

Guarantee:

-

One year against quality defects

-

Application:

-

Cement plant ,quarry ,power plants,mining

-

Physical property:

-

impact hardness

-

Chemical control:

-

Spectrum tester(analyser)

-

Quality tester:

-

Ultrasonic fault detector

-

Testing:

-

Hardness, flaw detector test

-

Certificate:

-

BV certificate ,ISO2008

-

Certification:

-

BV certificate ,ISO2008

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHILI

-

Local Service Location:

-

None

-

Hardness:

-

more than 229HB

-

Heat treatment:

-

Anneal,quenching ,tempering

-

Guarantee:

-

One year against quality defects

-

Application:

-

Cement plant ,quarry ,power plants,mining

-

Physical property:

-

impact hardness

-

Chemical control:

-

Spectrum tester(analyser)

-

Quality tester:

-

Ultrasonic fault detector

-

Testing:

-

Hardness, flaw detector test

-

Certificate:

-

BV certificate ,ISO2008

-

Certification:

-

BV certificate ,ISO2008

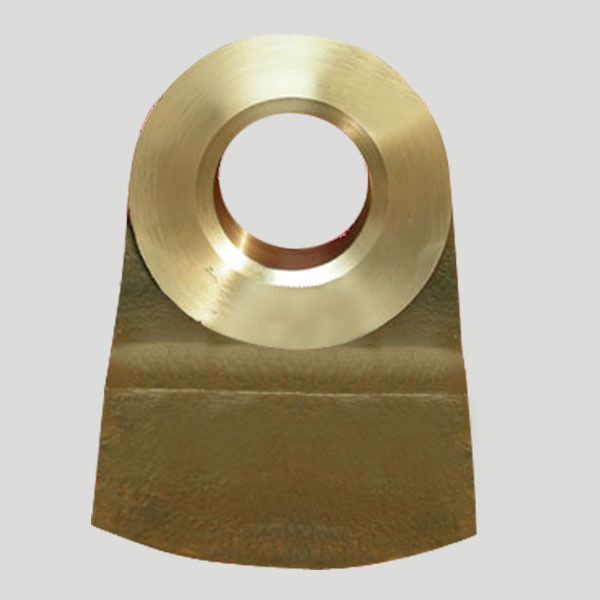

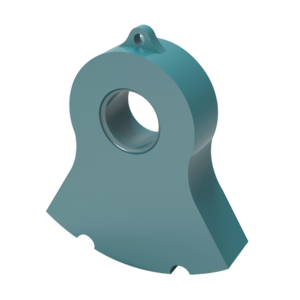

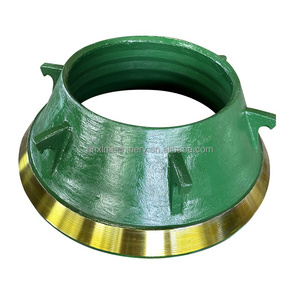

hammer crusher spare wear parts High Manganese hammer mainly used in the field to withstand shocks, extrusion, and etc bad working conditions The most important characteristic of high manganese hammer is under the condition of strong shocks extrusion, the surface of the hammer will rapidly appear hardening phenomenon, makes it hearts remained austenite of good toughness and meantime the hardening layer with good wear resistance. This is not possible for the other material. But the wear resistance of high manganese hammer is only under the condition of have enough power to form the hardening surface, otherwise the performance is very poor.

Features of hammer crusher spare wear parts high manganese crusher hammer

1) Perfect and technical design. Hammer designing plays a significant role in crusher efficiency. The hammers do most of the work in most types of crusher. Our hammer is tailor design for each customer as per technical drawing.

2) Science design of the hammer’s center of gravity. The center of gravity must be controlled to utilize the full mass of the hammer against the feeds. Our products had been tested by many site testing. They are welcome among the world.

3) Edge configuration of the hammer head. The edges of each hammer had specially treat to get the maximum serving life

4) Heat treating: Hammer hardness is most essential factor for the hammers’ serving life. Our hammer heat treatment are quenching, tempering,anneal.

Luoyang Zhili New Materials CO., Ltd was founded in 1992, Which specialized in producing wear- resistant steel company, professional of the crusher hammer. We passed the ISO9001:2000.

During 25 years we establish cooperation with many respected customer such as CRH(Ireland),POSCO(Korea),Holcim(Swden),CEMEX (Mexico, Egypt),ARCELORMITTAL (Algeria),Magaldi Power S.p.A.(Italy),IMCO Alloys Pvt. Ltd(India),CA POLYTECH PVT.LTD(India),LAFARGE(Morocco, Romania, China).

1.Q: What's your company's casting methods?

A:We support sand casting and lost foam casting.

2.Q: Can you make products without drawing?

A: No, we can only make products strictly follow customers' technical drawing.Because every spare parts must be install to the equipment.even little error can make big problem without technical drawing.

3.Q:What's brand do you manufacture?

A:We supply casting spare parts for many customers all over the world, OEM is accept.

4.Q:How long is your products' lifetime?

A: Even the same products,different working condition has different lifetime.So please let us know your working condition we can give you some technical suggestion.

5.Q:What's the delivery time?

A: Usually we the delivery time is 35 days. But we will arrange the Production Scheduling as customers' requirement.

6.Q:What's the payment term does your company accept?

A: 30%T/T in advance, the balance pay off before delivery.