- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OPCT

-

Model Number:

-

NO

-

Surface Treatment:

-

smooth

-

Material:

-

FRP GRP Fiberglass

-

Color:

-

yellow, red, white, black etc

-

Certificate:

-

ISO9001

-

Advantage:

-

Non-Conductive

Quick Details

-

Application:

-

Corrosion resistance

-

Technique:

-

pultruded

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

OPCT

-

Model Number:

-

NO

-

Surface Treatment:

-

smooth

-

Material:

-

FRP GRP Fiberglass

-

Color:

-

yellow, red, white, black etc

-

Certificate:

-

ISO9001

-

Advantage:

-

Non-Conductive

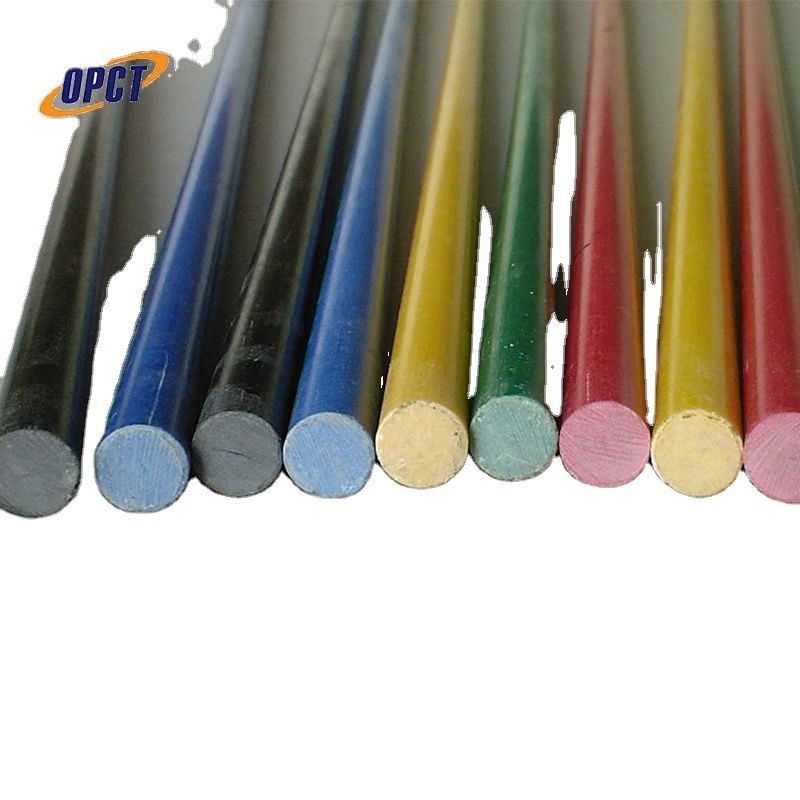

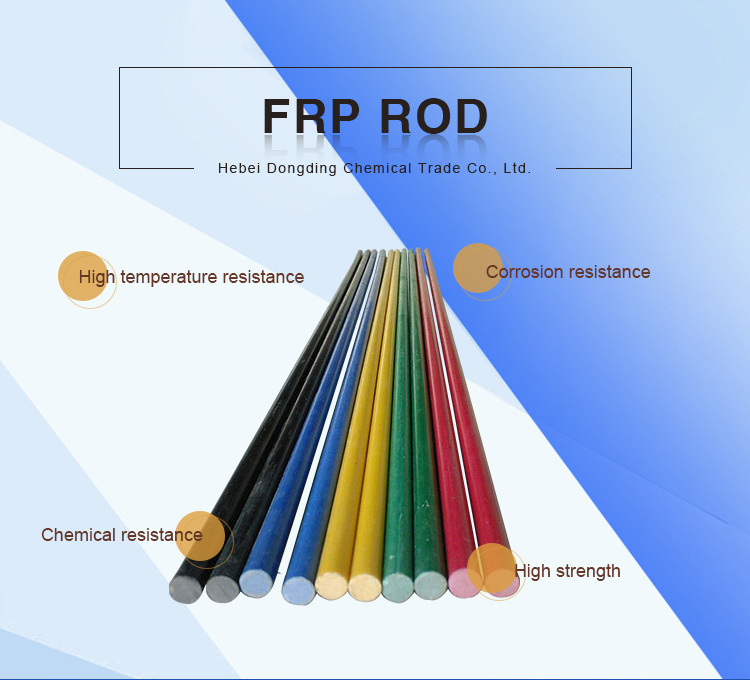

Frp Insulation Bar Solid Fiberglass Pole Rod Flat Strip

Product Description

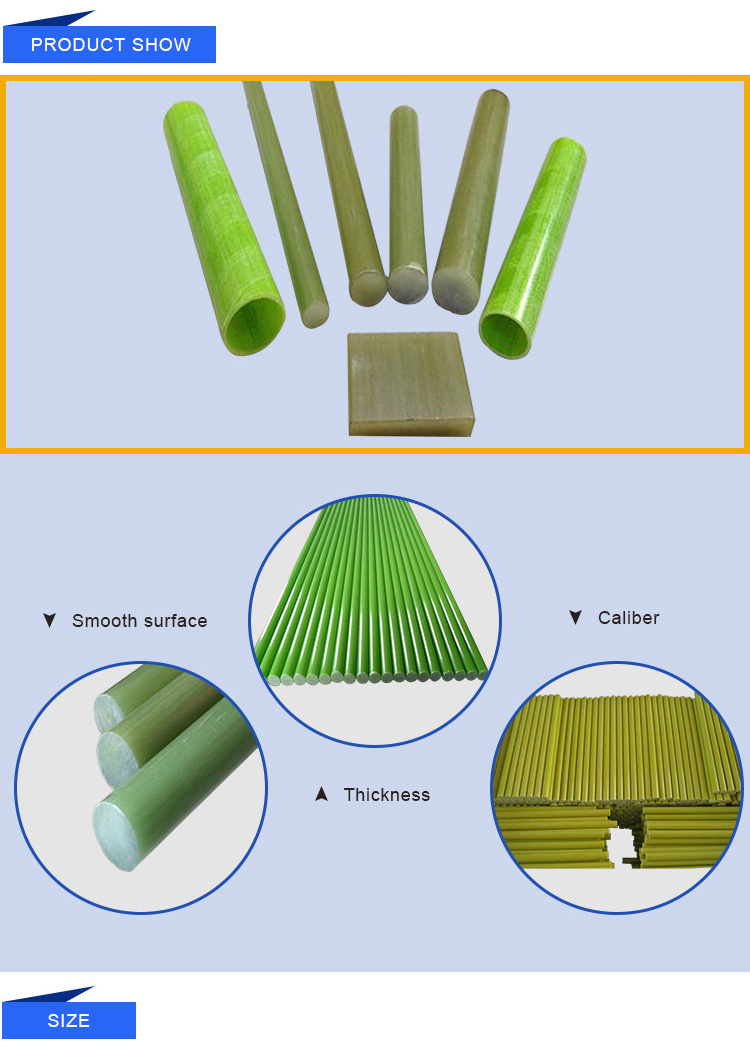

FRP rods which is one of its main products. The product is a kind of structural plates which uses high-strength fiberglass roving as reinforcing material, thermosetting resin as the base and then is cast and formed on a special metal mold.

|

Product name

|

FRP Fiberglass rods

|

|

Material composition

|

Fiberglass roving,resin,filler

|

|

Resin type

|

UPR, ISO

|

|

Color

|

Black , white , red , green , yellow , blue , grey or customized color

|

|

Surface

|

Smooth,Grit fine grit,Concave,Grit cover,Chequer cover

|

|

Certificate

|

ISO9001,SGS

|

|

Feature

|

Aging-Resistant,insulation,corrosion resistance

|

|

Size

|

Customised Size

|

|

Trade terms

|

EXW, FOB, CNF, CIF

|

|

Eco-Friendly

|

Yes

|

|

Shipping way

|

By sea/air/express

|

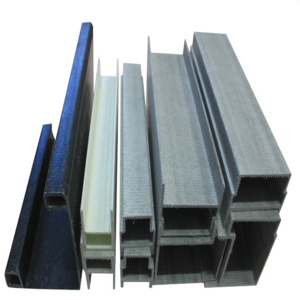

Series of our pultrusion profiles include square tube,rectangular tube,round tube,angle,I-beam,channel,rod and other custom profiles. Our company can be customized according to customer requirements, the product images and properties are for reference only, and the more details requested please contact us!

Application

FRP rods can be used in automotive,chemical processing,construction,duct rod / fish rods,electrical / utility,recreation,

corrosion resistant equipment marine,sporting goods,oil & gas, petrochemical,power generation, window shades, wastewater treatment, advertising panels, antennas and so on.

corrosion resistant equipment marine,sporting goods,oil & gas, petrochemical,power generation, window shades, wastewater treatment, advertising panels, antennas and so on.

>> Exceptional Strength:

reduce damage caused by accidental collisions

>> Light Weight: Weighing up to 80% less than steel and 30% less than aluminium

>> Corrosion Resistant: unaffected by exposure to a wide variety of corrosive chemicals and environments

>> Maintenance Free: The corrosion resistant properties remove the necessity of periodic painting or surface treatment.

>> Low Thermal Conductivity: around 1/250 of aluminium, and 1/60 of steel

>> Non Conductive: electrically non-conductive, ideal for cable trays, ladders, platforms

>> Electromagnetic Transparency: transparent to radio waves, microwaves and other electromagnetic frequencies

>> Dimensional Stability: resistant to stretching, warping, or swelling over a wide range of temperatures & physical stresses

>>Thermal Stability: withstanding continuous exposure to temperatures of up to 65 degrees centigrade

>> Easy to install and maintain

>> Rich color: there are many colors for you to choose

>> Light Weight: Weighing up to 80% less than steel and 30% less than aluminium

>> Corrosion Resistant: unaffected by exposure to a wide variety of corrosive chemicals and environments

>> Maintenance Free: The corrosion resistant properties remove the necessity of periodic painting or surface treatment.

>> Low Thermal Conductivity: around 1/250 of aluminium, and 1/60 of steel

>> Non Conductive: electrically non-conductive, ideal for cable trays, ladders, platforms

>> Electromagnetic Transparency: transparent to radio waves, microwaves and other electromagnetic frequencies

>> Dimensional Stability: resistant to stretching, warping, or swelling over a wide range of temperatures & physical stresses

>>Thermal Stability: withstanding continuous exposure to temperatures of up to 65 degrees centigrade

>> Easy to install and maintain

>> Rich color: there are many colors for you to choose

Production Process

Production process is a continuous production process to produce fiber-reinforced polymer profiles of any length and constant section. Reinforcement fibers may be roving, continuous mat, woven roving,carbon or others.

The fibers are impregnated with a polymer matrix (resin, minerals, pigments, additives) and passed through a pre-forming station that produces the stratification necessary to give the profile the desired properties. After the pre-forming step, the

resin-impregnated fibers are pulled through a heated die to polymerize the resin.

The fibers are impregnated with a polymer matrix (resin, minerals, pigments, additives) and passed through a pre-forming station that produces the stratification necessary to give the profile the desired properties. After the pre-forming step, the

resin-impregnated fibers are pulled through a heated die to polymerize the resin.

Packaging & Shipping

>> Packing:

Packaged by plastic film then bundled by rope.

>> Delivery: Within 15 days after the payment was received.

>> Delivery: Within 15 days after the payment was received.

Related Products

Hot Searches