The overall stability of the equipment is enhanced after the weight of the equipment increases.

- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

21

-

Name:

-

Top quality 3D foil Vacuum press machine for cabinet door laminating

-

Max sheet thickness:

-

Less than 0.4mm

-

Industry:

-

Woodworking products coating

-

Usage:

-

Film Laminating

-

Package:

-

PE film & polywood & steel tube

-

Voltage:

-

380v 50hz 3 Phase

-

Case coating:

-

Electrostatic spray

-

Applicable material:

-

PVC film, heat transfer film etc

-

Working area:

-

2600*1100 mm

-

Color:

-

Customer Requirement

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BYT

-

Weight (KG):

-

800 KG

-

Power (kW):

-

21

-

Name:

-

Top quality 3D foil Vacuum press machine for cabinet door laminating

-

Max sheet thickness:

-

Less than 0.4mm

-

Industry:

-

Woodworking products coating

-

Usage:

-

Film Laminating

-

Package:

-

PE film & polywood & steel tube

-

Voltage:

-

380v 50hz 3 Phase

-

Case coating:

-

Electrostatic spray

-

Applicable material:

-

PVC film, heat transfer film etc

-

Working area:

-

2600*1100 mm

-

Color:

-

Customer Requirement

Customer Feedback

England

England customer use our pvc vacuum press machine for

wall decoration

making

Mexico

Mexico customer use our PVC Membrane press machine finish

door and cabinet board

making

Products Description

Application:

It is used to cover PVC, wood, wood veneer, decorative paper and similar materials on the surface of all types of door, cabinet and furniture.

PVC Foil film vacuum membrane press machine for MDF cabinet kitchen door PVC laminating

Features:

1.Wide application,material is heat transfer film,PVC film and etc.It is professional in making PVC wood door,cabinet,other wood furniture.

2.Intelligent temperature controller,heating area adopt energy-gathered reflecting cover,save electricity.

3.Heating tubes are special customized from our factory,can run 24 hours continuously,service life 8000-10000mm,make sure heating material balanced,can’t partial rupture.

4.Heating box is controlled by cylinder,tight closed,beautiful appearance.easy to open and close.

5.Compact structure,easy to operation,takes up small area,no special requirement for factory and infrastructure.can begin production after short training for staff.

|

Products Name

|

PVC Foil film vacuum membrane press machine

|

|

Model

|

BFM-2600

|

|

Working table size

|

2600*1100mm/102*43″

|

|

Total power

|

20.5kw

|

|

The Max. thickness of PVC film

|

0.5mm/.02″

|

|

The Max. forming height

|

50mm/2″

|

|

Power supply

|

380v 50hz 3Phase (or customized)

|

|

Working air pressure

|

-0.7~-0.1Mpa

|

|

Net weight

|

900kgs

|

|

Machine’s size

|

2750*1550*1370mm

|

Products Advantage

Whole machine net weight meet

900KGS

, Other supplier same machine about

600KGS

.

Adopt special thickened

40mm

insulation layer , Other supplier use 20mm-30mm

During heating the thickening of insulation layer improves the insulation effect and saves resources.

Use SC80*300 double cylinder,which can meet

500KG

opening force, the connecting lever thickness meet

20mm

.more safety . For other supplier connecting lever only about 10mm .

Our machine is

automatic film laminating machine

,when the vacuum storage tank pressure is insufficient,the vacuum pump will working automatically ,this way also extend the service life of vacuum pump . But for other supplier usually is manual and without vacuum storage tank.

5.PVC film thickness

Until now we tested the max. membrane press film thickness meet

0.5mm

6.Easy movement

Install four wheels on the machine bottom, easy movement .

7.Two inspection window

This way it is more easy to check the inside working condition .but for other supplier only have one inspection window

8.Install the

retainer frame

,more convenient for use .

Related products

PVC laminating

Bark laminating &plywood bend

Corian Bending

Customized products

Function customized

Max forming height meet 200mm/8inch

Color Customized

Painting the color according customer need

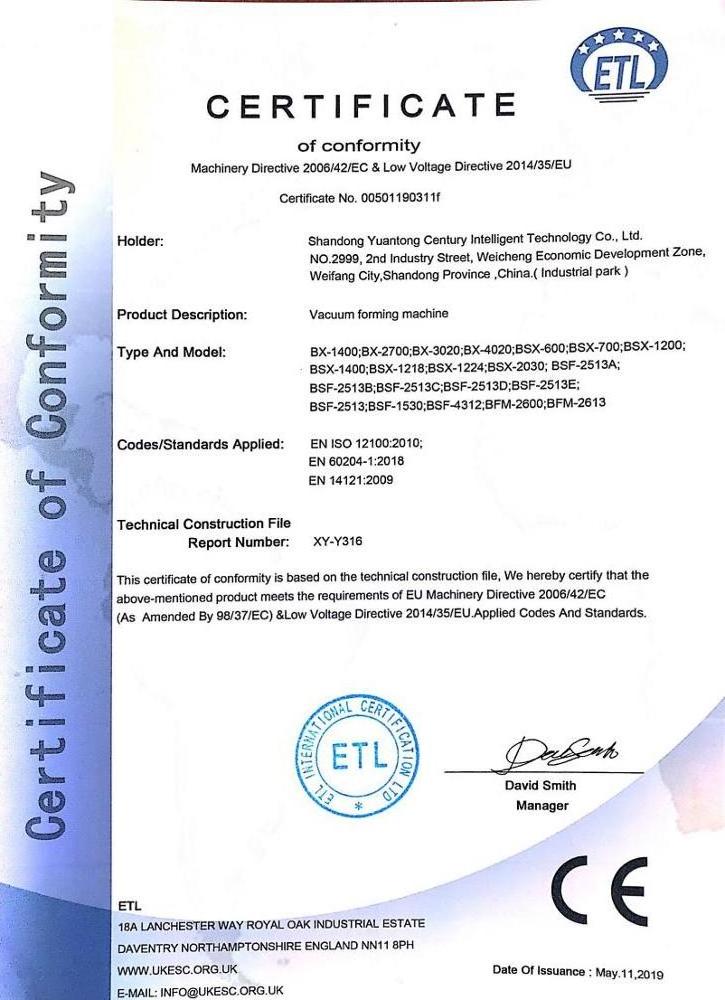

Certifications

Producer SGS Certification

Products quality CE Certification

Brand registration

Hot Searches