- Product Details

- {{item.text}}

Quick Details

-

Coil Number:

-

Two windings

-

Place of Origin:

-

China

-

Brand Name:

-

SafeHerm

-

Model Number:

-

SafeHerm-75/13.8

-

Product name:

-

Power distribution transformer

-

Type:

-

Oil immersed type

-

Rated capacity:

-

75kVA

-

Primary voltage:

-

13.8/13.2

-

Secondary voltage:

-

240/120

-

Frequency:

-

50/60Hz

-

insualtion voltage:

-

75kV/35kV

-

Standard:

-

IEEE C57.12.00

-

Cooling Method:

-

ONAN

-

Vector group:

-

Dyn11, Yyn0

Quick Details

-

Use:

-

Power Distribution

-

Phase:

-

Single

-

Coil Structure:

-

TOROIDAL

-

Coil Number:

-

Two windings

-

Place of Origin:

-

China

-

Brand Name:

-

SafeHerm

-

Model Number:

-

SafeHerm-75/13.8

-

Product name:

-

Power distribution transformer

-

Type:

-

Oil immersed type

-

Rated capacity:

-

75kVA

-

Primary voltage:

-

13.8/13.2

-

Secondary voltage:

-

240/120

-

Frequency:

-

50/60Hz

-

insualtion voltage:

-

75kV/35kV

-

Standard:

-

IEEE C57.12.00

-

Cooling Method:

-

ONAN

-

Vector group:

-

Dyn11, Yyn0

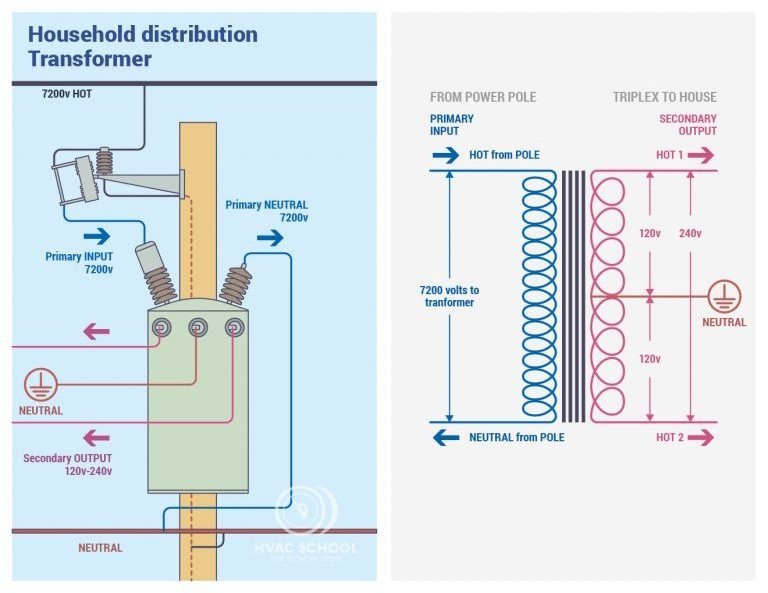

IEEE/ANSI standard Single phase transformer

The single-phase pole-mounted distribution transformers are specifically designed for the decentralization distribution network of servicing residential overhead distribution loads of town and countryside. They are also suitable for light and diversified power applications. These transformers are designed for the application conditions normally encountered on electric utility power distribution systems.

Applicable Standards

IEEE C57.12.00 C57.12.20 ANSI C57.12.00 C57.12.20 IEC 76 GB10318

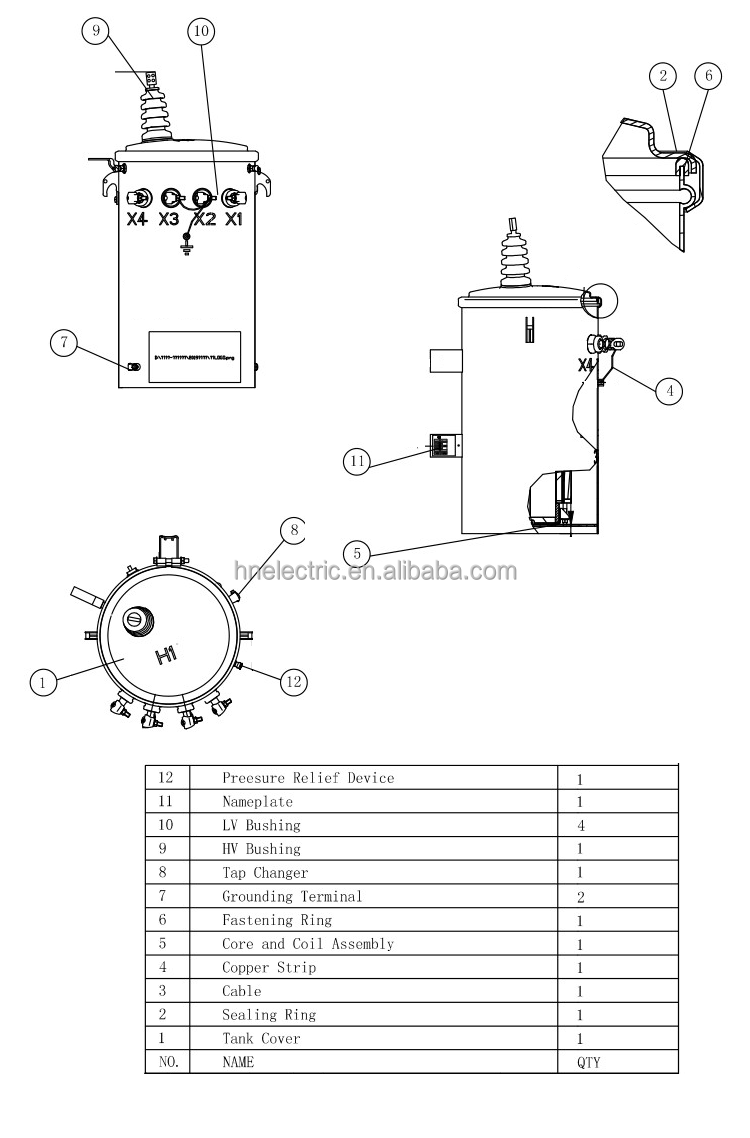

Features of outer structure

(1) Cover mounted high voltage porcelain bushings with eyebolt terminals are mounted on flat embossments on the cover and have undercut gasket seats for improved sealing. The eyebolt connectors are cast bronze plated with tin to accommodate both aluminum and copper conductors.

(2) One-piece fasten ring prolongs the life of the transformer, facilitates inspection and maintains even pressure around the entire rim. It combines with a specially formed tank rim, drawn cover and gasket to form an effective seal which will not deteriorate with age.

(3) Low voltage tank-wall bushing terminals are clamp type and tinplated.

(4) Tank is equipped with self- sealing pressure release device.

(5) Support lugs, welded to the tank, conform to ANSI standards are made of hot-rolled steel.

(6) Tank is supplied with a tank grounding bolted ring-type connector suitable for use with copper or aluminum.

|

|

Our transformers are designed and manufactured through verification from the design stage using design program, electromagnetic field analysis program, and structural analysis program

- Dielectric Strength

| Our transformers guarantee dielectric strength to withstand impulse voltage thanks to high-technology design which ensures low capacitance between winding and the ground and proper coordination of insulating material and solves creepage problem. |

- Thermal Capability

| Heat generated from coils which form electric circuit inside the transformer and heat from iron cores form magnetic circuit and is transmitted to insulating oil. Heat transmitted to insulating oil radiates to the air through the cooler. Cooling effect is very important as it is directly linked to insulation life and the capacity of the transformer. Our transformers lay emphasis on improving cooling performance and regulating temperature of the hottest spots by using an effective cooling system. |

- Mechanical Strength

| Reliability of transformers manufactured by us is excellent because of winding and tank design which distributes mechanical force evenly in case of short circuit and supports short-circuit strength effectively. |

Manufacture Procedure

01 Windings

Windings are composed of two parts, namely, a conductor and insulation material. For the conductor, we use high grade electrolytic copper or aluminium. Our Oil Immersed Transformers obtain high thermal capacity with the use of Epoxy coated Insuldur Kraft Paper, which has higher short time overload capacity than any other Kraft paper type.

02 Core

Core design is essential because it determines the transformer’s efficiency and noise level. For high dimensional accuracy, the core cutting processing of us is controlled by a computerized system. By Step-Lap core stacking, Our Oil Immersed Transformers attain to optimal characteristics for each customer.

03 Winding Support System

Coils are sized and clamped by being pressed with a special hydraulic fixture after assembly with the core. With Axial and Radial direction, we reinforce the winding support system. This secure structure helps withstand harsh short circuit forces.

04 Radiator

The transformer will be furnished with panel or corrugated radiators assuring that the temperature rise of the windings or oil will not exceed their specified limit when the transformer continuously operates at the rated full load.

Glances in workshops:

Why choose us

| Hunan Electric Union is a diverse electric equipment manufacturer group located in middle south of China. |

| Limit Innovation |

|

We are in a traditional business since transformers and switches are developed over hundred years, even

the so called “new technologies” of cast resin technology, vacuum arc distinguish technology and digital

policy on our mature products |

|

1. Update products only if latest standards revision officially issued

2. Produce new products only if related technology are maturely developed. 3. Focus limit innovation on external updates to make products easy to use and transport. |

| Our Mission |

|

progress, the manufacturing industries have gradually entered a world-class level, and many well-known

international companies

have chosen to set up factories in China.

so our mission is to provide the most cost effectiveproducts to world,

and these products are transformed to meet relevant international

Eventually, we could help the developing regions to update their energy quality and improve people’s life. |

|

Products

2. Gas insulated switchgear (GIS) 72.5-252kV

11. Compact Substation |

|

Services

|

|

Products Features

We defined four rules to estimate our products, 1. Standards: All products should comply with IEC or IEEE standard codes. 2. Requirements: All products should comply with technical agreement from end user. 3. Easy to Use: All products should tested in factory and deliver with full, readable drawings and manuals. 4. Fit to Container: All products should designed to load on a container. |

Customers all over the world:

Product packing:

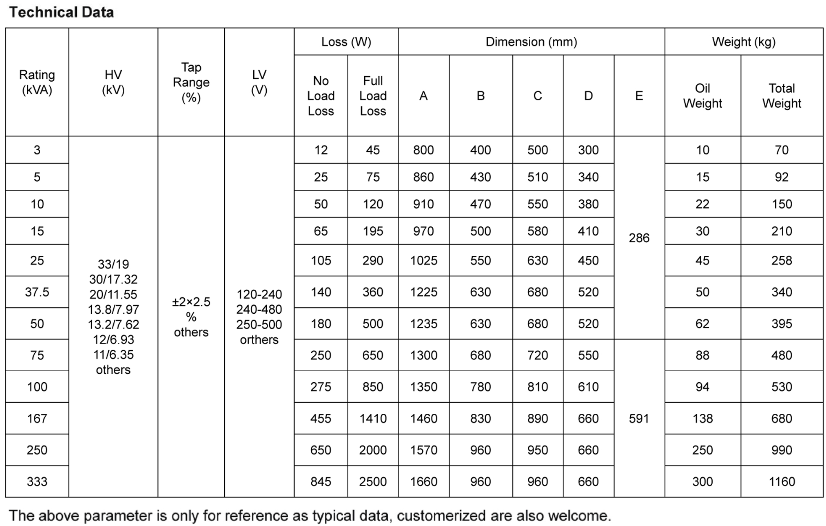

More rated capacities are available

Send your technical requirement to my whatsapp, wechat or email, We could work together to win a project contract.