- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ 3P (Customizable)

-

Power:

-

38-285KW

-

Dimension(L*W*H):

-

Depends On The Daily Capacity

-

Weight:

-

15000 kg

-

Product Name:

-

small scale crude oil refinery

-

Total Oil Output Rate:

-

92%-96%

-

Total Processing Cost Per Ton:

-

19-21 USD

-

Application:

-

Small Scale Petroleum Refinery Mini Crude Oil Refinery For Sale

-

Heating Method:

-

Direct Heating

-

Chemical Addictives:

-

NO Acid NOR Clay

-

Function:

-

Small Scale Petroleum Refinery Mini Crude Oil Refinery For Sale

-

Main End Products:

-

Diesel Fuel/Gasoline/Heavy Oil Residue

-

Available Raw Materials:

-

Crude Petroleum Oil

Quick Details

-

Flow:

-

25TON/DAY

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

Junneng

-

Voltage:

-

380V 50HZ 3P (Customizable)

-

Power:

-

38-285KW

-

Dimension(L*W*H):

-

Depends On The Daily Capacity

-

Weight:

-

15000 kg

-

Product Name:

-

small scale crude oil refinery

-

Total Oil Output Rate:

-

92%-96%

-

Total Processing Cost Per Ton:

-

19-21 USD

-

Application:

-

Small Scale Petroleum Refinery Mini Crude Oil Refinery For Sale

-

Heating Method:

-

Direct Heating

-

Chemical Addictives:

-

NO Acid NOR Clay

-

Function:

-

Small Scale Petroleum Refinery Mini Crude Oil Refinery For Sale

-

Main End Products:

-

Diesel Fuel/Gasoline/Heavy Oil Residue

-

Available Raw Materials:

-

Crude Petroleum Oil

Since established,Junneng always presents itself as market-oriented.Based on the high-tech development we use our human source and technology as our advantages and take “Be Part Of The Solution,Not The Pollution.” as our responsibility.Our company has developed into an oil recycling & regeneration production base.

After years of learning,studying and improving the edgy technology of various highly-advanced oil filtration and purification worldwide,we’ve developed 8 series of oil regeneration equipment in hundreds of size and specifications.These series of equipment have earned lots of compliments and approvals from our customers,for playing an irreplaceable role in reducing cost & energy consumption and the pollution among various fields like oil refinery,electricity,petrochemical industry,metallurgy,mining,aviation,vessel and railway industry etc.

In the last few years,we’ve successfully developed 2 series of waste oil regeneration equipment,during which the cost and energy consumption got reduced;the recovery output rate got increased and the quality of reprocessed oil got improved without the need of acid and activated clay.We offer customized solution based on our clients’ needs and requirements.Our equipment has been shipped to both the domestic and international markets.We would be honored to cooperate with our new customers leading a vast prospect of safety,energy-saving and eco-friendly.

With the teamwork we’re now working on a more vast field of oil filtration to create more various and more developed oil regeneration equipment.

We’re determined to be the pioneer of technology in our field.Based on the management ideas of “Quality brings up the brand;Service earns the clients”,we will be dependable for our clients from the get-go.

We aim to regenerate hazardous wastes;reduce costs and create benefits.Believe us,believe your own choice.

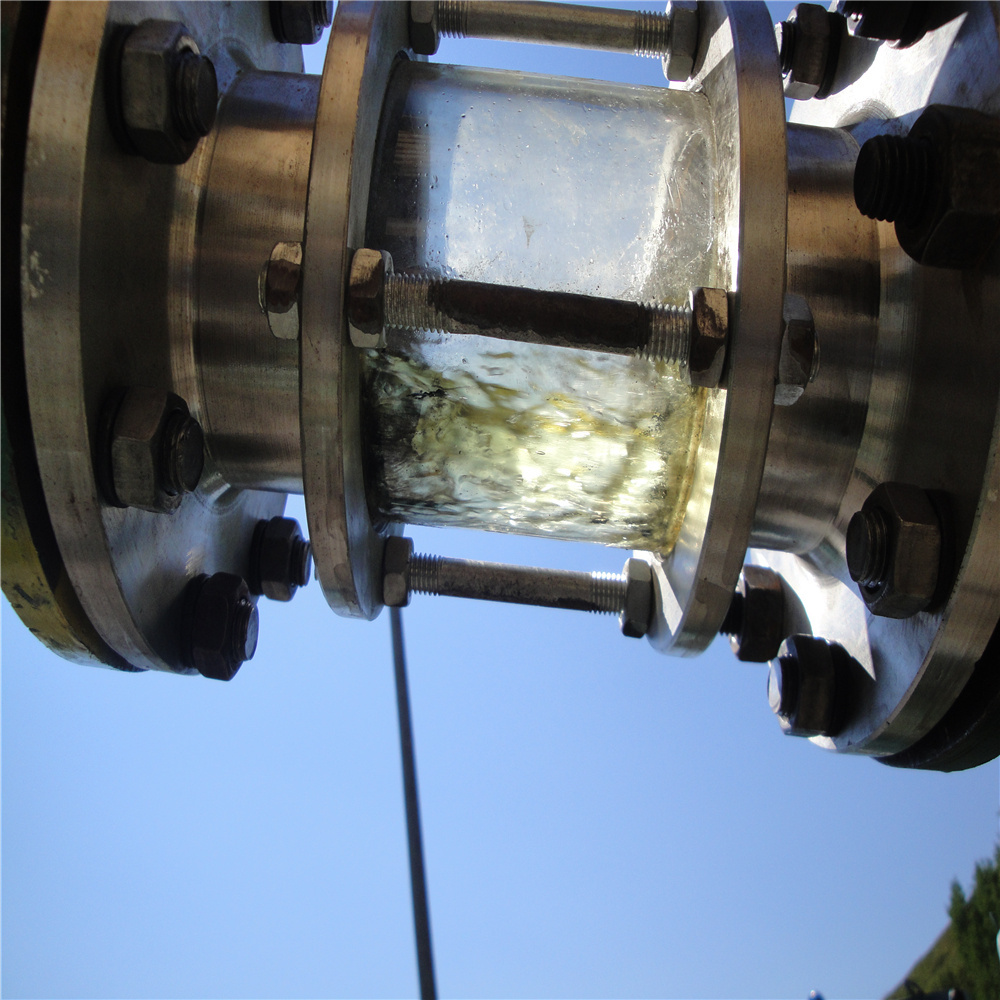

<1>

The raw material oil gets pumped into the heater and works it to its working temperature via fuel oil/gas/coal.

<2>

The MAXIMUM working temperature is about 410 °C.

<3>

The required quality diesel fuel and gasoline can be obtained after catalytic distillation process.

<4>

When the reaction of the raw material is complete.it will stop heating automatically.

<5>

<6>

After that the machine set can be used again.

Main Features

[1]

not doing it the traditional way,no acid,alkali nor clay added during the whole process

[2]

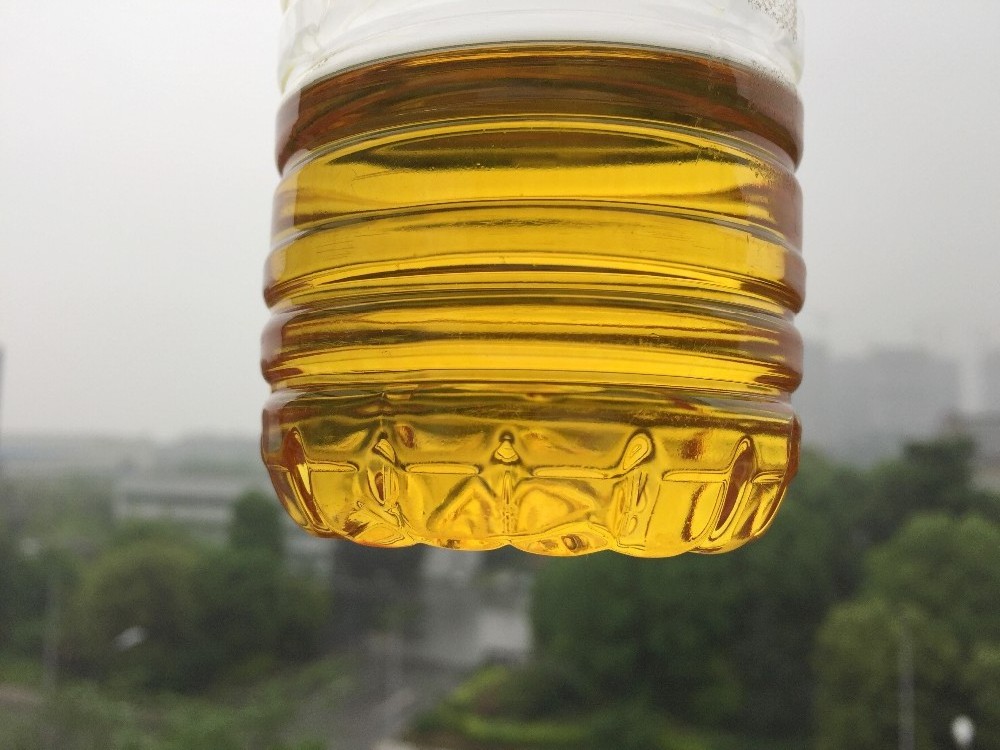

the oil we get after refining:great flammability and flow property

[3]

no acid,activated clay needed.Uses a special way of heating with high thermal efficiency so it doesn't form carbon deposition easily

[4]

total oil output rate at 92%-96%

[5]

no smell and no color changing after

[6]

oil color after treatment:yellow

[7]

no further maintenance cost

[8]

durable,more importantly,it's safe and environmental-friendly since the whole process is all sealed and it won't release any harmful gas to human and the environment

[9]

easy to operate and low on labor intensity,only 1-2 workers are enough to run the machine

[10]

you're welcome to pay site visits and you can bring your own oil as well so you can see the process from the oil in and refined oil out

[11]

no extra filtration needed after we get the final oil through the machine,you can use or sale them directly

Reaction Tank

The to-be-processed oil will get pumped into this tank through the primary filter.

By burning fuel oil or using gas,we can work the oil temperature up to the setting value.

Thermal Insulation System

This system equips along with the heating system,to preserve the heat at a steady state.

Catalyst System

With catalytic effect,the oil reaches the expected temperature and the gaseous hydrocarbons become diesel and gasoline compositions.

Cooling System

After the catalytic process,the diesel and gasoline compositions we get will be condensed into liquid materials.

Temperature-Control System

So the oil transformed into diesel fuel and gasoline.While the oil is dried by distillation,it will stop heating timely.

Tail Gas Handling System

There will be a small amount of un-liquefied gas left,all of which can meet the emission standards through tail gas system.

DIESEL FUEL

86%-88%

OIL RESIDUE

6%-8%

5%-6%

Advanced Distillation System

Makes it Different from other equipment on the market:Uses a special way of heating with

high thermal efficiency

,the distillation kettle has a

special stirring system

in it and the molecules could get stirred thoroughly and

balance the heat

at the bottom so that it doesn’t form carbon deposition easily, which greatly reduces your maintenance costs.

Developed Processing Technology

Normal Pressure

Vacuum Distillation

NO Acid NO Clay No Other Chemical Addictives

Catalyst Only.

NO ACID:so it won't affect the quality of the refined oil.

NO CLAY:so it lowers the total operating cost.

Available For Overseas Adjusting and Installation

Workers with electricity experience with be recommended.

Our engineers will go overseas to help with all that and will keep following that way in the following years.

YES to the Environmental Emission Standards

Used Catalyst :Same Components As Earth

Gas During The Refining Process : The distillation process is completely sealed with high thermal efficiency stirring system tail gas-handling system so it won't release any harmful gas to human and the environment.

1. What Is the Machine Price,Shipping/Transportation Cost,Land Area Required and Delivery Time?

All of which will be depending on the following quetions: a)What is the raw material you're planning to process? b)What is the end/final product you'd expect to get through the machine? c)What is the daily capacity ?,so we can confirm on the machine size,costs,containers it needs for shipping etc.

2. Are Site-Visits Available?

Yes ,you're welcome to bring your own oil sample for testing as well.We have mini versions of the machine series back in the factory so you can see the process from the raw material in and the good oil coming out.

3.The Total Consumption Required Processing 1 Ton?

Except the labor fee,the total processing cost per ton is about 19$USD,including electricity,catalyst,fuel cost.