- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

200L

-

Weight (KG):

-

400 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

110*110*110cm

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2023

-

Product Name:

-

300L 500L 1000L oil based emulsion paint mixing machine

-

Capacity:

-

100L~20000L

-

Mixing speed:

-

6-8 Minutes

-

Structure:

-

single shaft or double shaft as customized

Quick Details

-

Barrel Volume (L):

-

200

-

Max. Loading Volume (L):

-

200 L

-

Range of Spindle Speed(r.p.m):

-

1 - 1480 r.p.m

-

Max. Loading Capacity:

-

200L

-

Weight (KG):

-

400 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

110*110*110cm

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2023

-

Product Name:

-

300L 500L 1000L oil based emulsion paint mixing machine

-

Capacity:

-

100L~20000L

-

Mixing speed:

-

6-8 Minutes

-

Structure:

-

single shaft or double shaft as customized

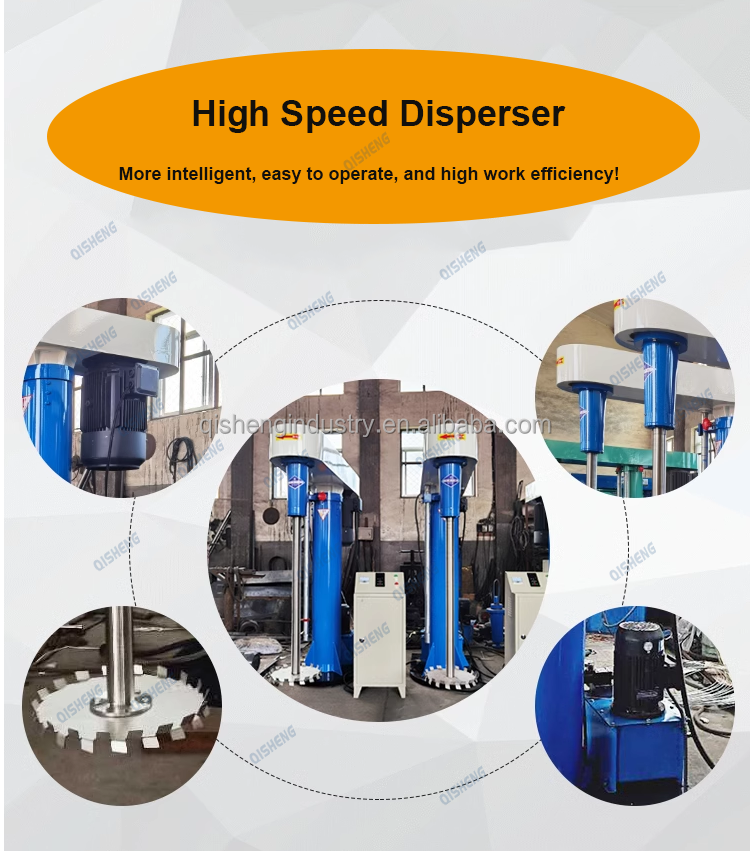

Automatic high speed industrial paint color mixing dispersion machine 300L 500L 1000L oil based emulsion paint mixing machine

Product Description

Introduction :

High speed disperser main machine adopts electromagnetic speed regulation or frequency conversion speed regulation, stable and powerful operation, suitable for various viscosity; hydraulic and mechanical lifting forms, lifting and rotating freely, adapt to various positions; common and explosion-proof configuration, safe and reliable, simple operation and maintenance; continuous production Strong in nature, the material can be quickly dispersed and dissolved, the dispersion effect is good, the production efficiency is high, the operation is stable, and the installation is simple.

Application:

High speed dispersers can mix, dissolve and disperse two or more liquid and powder substances. It can be used alone or in combination with other beads mill. This machine is suitable for mixing, dissolving and decomposing materials such as ink coating, epoxy floor paint, dye, resin, pigment, lotion, adhesive, etc.It is suitable for the production of paint, ink, coating, dye, paper and so on in the chemical industry. It is used for the wet dispersion and mixing of liquid and solid materials.

Features:

1. Disperser blades adopt stainless steel material with structure firm, durable use.

2. High energy, low noise, strong power , double oil seal structure, high Oil leakage resistance.

3. Can be equipped with multiple stainless steel pull cylinder according to user requirements for alternate use. Improve work efficiency.

4. High quality electronic control equipment, more accurate, more precise.

5. A multi-purpose machine, mixing and dispersing to meet the needs of laboratory mixing and dispersing grinding and mass production of a variety of materials.

Parameter:

|

Model

|

Lifting stroke

|

Diameter

|

Main power

|

Hydraulic station power

|

|||

|

QS-150

|

80cm

|

150mm

|

3kw

|

1.1kw

|

|||

|

QS-250

|

120cm

|

250mm

|

7.5kw

|

2.2kw

|

|||

|

QS-300

|

120cm

|

300mm

|

11-15kw

|

2.2kw

|

|||

|

QS-350

|

120cm

|

350mm

|

18.5-30kw

|

2.2kw

|

|||

|

QS-400

|

120cm

|

400mm

|

30-37kw

|

2.2kw

|

|||

|

Remarks

|

|

Above data is just for reference.Different materials moisture ,density,capacity request ,the parameter may has Subtle gap difference ,Please refer to the actual situation.

|

|

|

|||

Recommend Products

Packing & Delivery

Packing: Nude or plywood case or as request

Delivery Date: 7-20 days after confirm the down payment according to order quantity and buyer's request.

Shipping Method: By sea

Shipping Port: Qingdao, China

Why Choose Us

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life

Hot Searches