- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380-480V

-

Power:

-

100KW

-

Weight:

-

4500 KG

-

Dimension(L*W*H):

-

30*5*5

-

Product name:

-

Cooling Dry Pet Dog Food Processing Making Machines

-

Pellet size:

-

1-8mm

-

Floating time:

-

>12hours

-

Screw diamete(mm):

-

70mm

-

Key Selling Points:

-

High Productivity

-

Usage:

-

fish , dog,Pet feed production

-

Machine material:

-

National Standard Carbon Steel

-

Advantage:

-

Easy Operation High Efficiency

-

web:

-

www.fldmachine.com

-

engineer service Whatsapp:

-

+86-152 6410 2980

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FLD

-

Voltage:

-

380-480V

-

Power:

-

100KW

-

Weight:

-

4500 KG

-

Dimension(L*W*H):

-

30*5*5

-

Product name:

-

Cooling Dry Pet Dog Food Processing Making Machines

-

Pellet size:

-

1-8mm

-

Floating time:

-

>12hours

-

Screw diamete(mm):

-

70mm

-

Key Selling Points:

-

High Productivity

-

Usage:

-

fish , dog,Pet feed production

-

Machine material:

-

National Standard Carbon Steel

-

Advantage:

-

Easy Operation High Efficiency

-

web:

-

www.fldmachine.com

-

engineer service Whatsapp:

-

+86-152 6410 2980

Product Detail

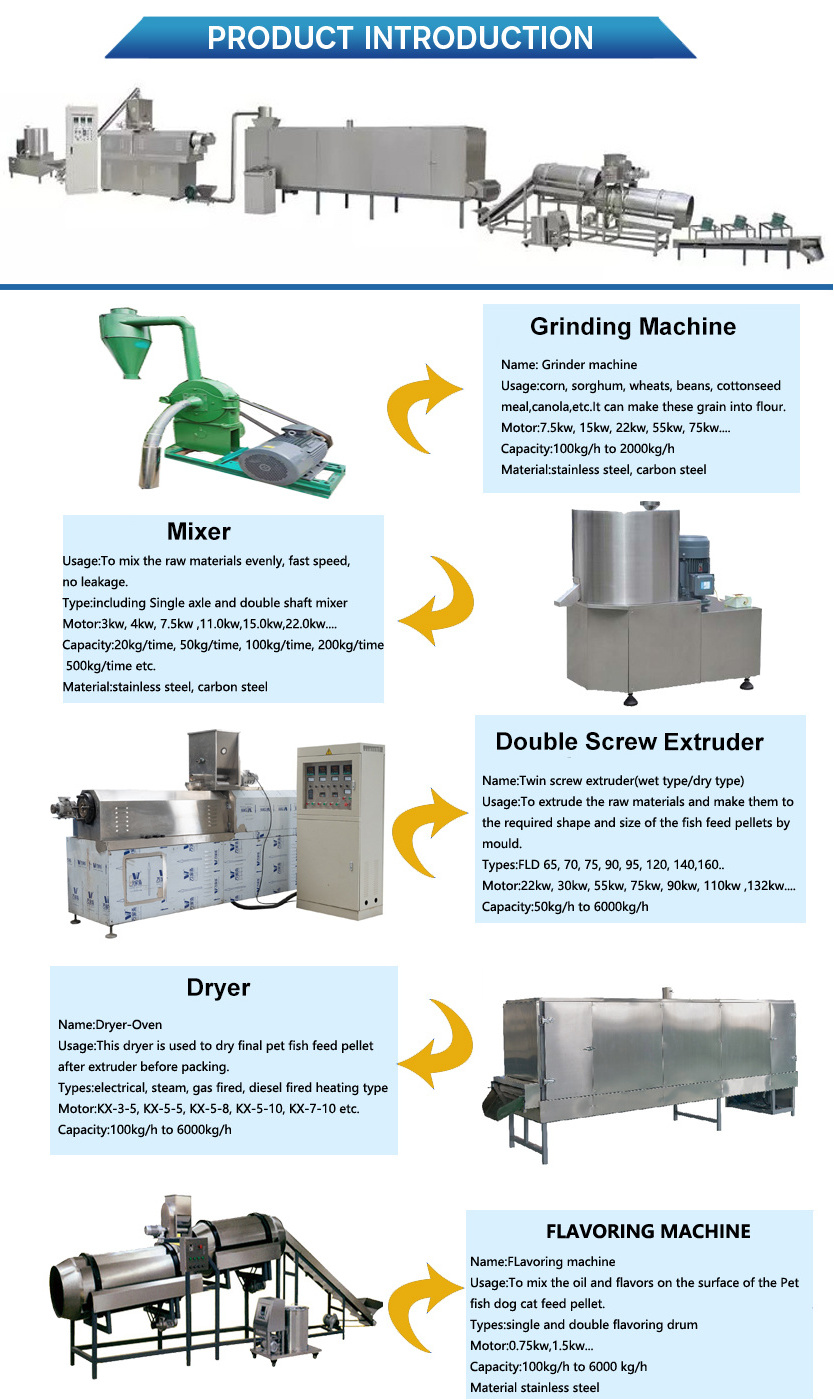

Fully Automatic Dry Dog Cat Pet Food Production Line Animal Feed Pellet Making Machine With Twin Screw Extruder

Description of

Dry Pet Dog Food Processing Making Machines

:

Twin screw extruder is deliberately made for special feed, which needs high in-shape rate and good-looking appearance. It is mainly used for sinking/floating/slow sinking aqua feed and pet food. Effectively protect the aquaculture water body from pollution to improve the quality of life.

Pet food making machine Application

Dry pet dog food processing making machines are widely used in the pet food industry. These machines are designed to produce dry dog food in large quantities efficiently. They are equipped with advanced technology and features that ensure the production of high-quality pet food.

The application areas of dry pet dog food processing making machines include pet food factories, pet food production lines, and pet food manufacturing units. These machines are capable of processing various ingredients such as meat, grains, vegetables, and vitamins to create a balanced and nutritious diet for dogs.

Moreover, these machines can produce different shapes and sizes of dry dog food, including kibbles, pellets, and biscuits. They have the capability to control the temperature, moisture, and cooking time, ensuring the optimal production of dry dog food.

The application areas of dry pet dog food processing making machines include pet food factories, pet food production lines, and pet food manufacturing units. These machines are capable of processing various ingredients such as meat, grains, vegetables, and vitamins to create a balanced and nutritious diet for dogs.

Moreover, these machines can produce different shapes and sizes of dry dog food, including kibbles, pellets, and biscuits. They have the capability to control the temperature, moisture, and cooking time, ensuring the optimal production of dry dog food.

In conclusion,

Fully Automatic Dry Dog Cat Pet Food Production Line Animal Feed Pellet Making Machine With Twin Screw Extruder

are essential tools in the pet food industry. They play a crucial role in producing high-quality, nutritious, and delicious dry dog food for our furry friends.

PRODUCT PARAMETER

|

Model

|

SLG65

|

SLG70

|

SLG75

|

SLG85

|

SLG95

|

|

Installed power

|

76kw

|

95kw

|

140kw

|

178kw

|

280kw

|

|

Production Capacity

|

120-150kg/h

|

200-260kg/h

|

300-400kg/h

|

400-600kg/h

|

1.0-2.0 T/H

|

|

Size MM

|

1600*1800*2000

|

1800*2000*2200

|

2000*2000*2200

|

2500*2600*3000

|

3000*3200*3500

|

OUR SERVICES

Our Services

1).Provide factory layout according to your factory size in advance;

2).Provide the basic formula;

3).Inspect the machine before leaving the factory; Oversea installation and commissioning equipment;

4).Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to

maintain machines during daily working;

5).Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide

technology support with you forever;

6).Provide English Version of Installation / Operation / Service / Maintenance Manual.

2).Provide the basic formula;

3).Inspect the machine before leaving the factory; Oversea installation and commissioning equipment;

4).Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to

maintain machines during daily working;

5).Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide

technology support with you forever;

6).Provide English Version of Installation / Operation / Service / Maintenance Manual.

Hot Searches