- Product Details

- {{item.text}}

Quick Details

-

Material:

-

304 Stainless Steel

-

Function:

-

Multifunction

-

Application:

-

Spring roll wrapper, lumpia wrapper, crepe

-

Capacity:

-

800pcs/h

-

Feature:

-

Full Automatic

-

Advantage:

-

Automatic, Easy operation

-

Raw material:

-

Flour

-

Keyword:

-

Spring Roll Wrapper Machine

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Online support

-

Product name:

-

Spring Roll Sheet Making Machine Spring Roll Wrapper Machine

-

Material:

-

304 Stainless Steel

-

Function:

-

Multifunction

-

Application:

-

Spring roll wrapper, lumpia wrapper, crepe

-

Capacity:

-

800pcs/h

-

Feature:

-

Full Automatic

-

Advantage:

-

Automatic, Easy operation

-

Raw material:

-

Flour

-

Keyword:

-

Spring Roll Wrapper Machine

-

Certification:

-

CE ISO

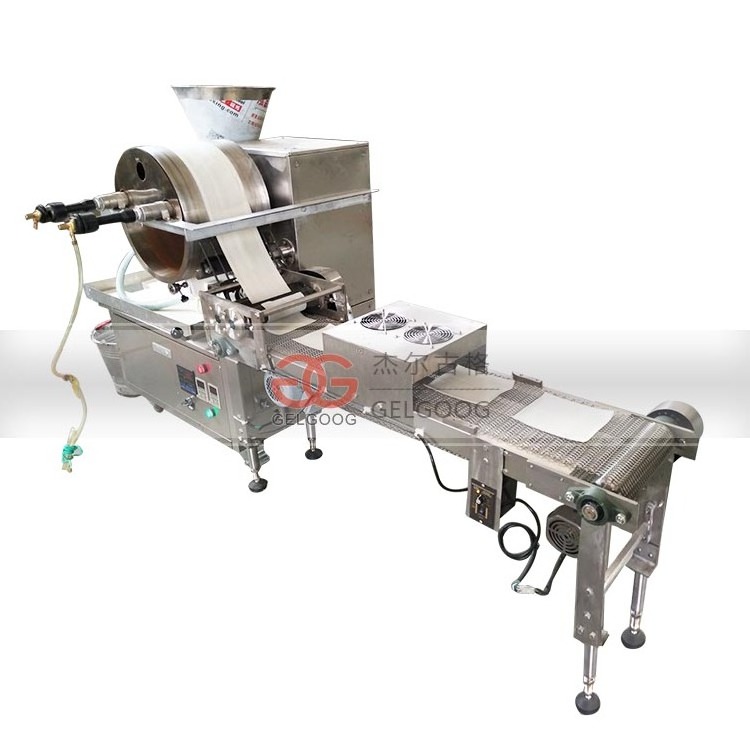

Full Automatic Spring Roll Sheet Making Machine Spring Roll Wrapper Machine

Wechat/Mobile/Whatsapp:0086-18539906810, ,Email:alice @gelgoog.com.cn

Function Spring Roll Sheet Making Machine:

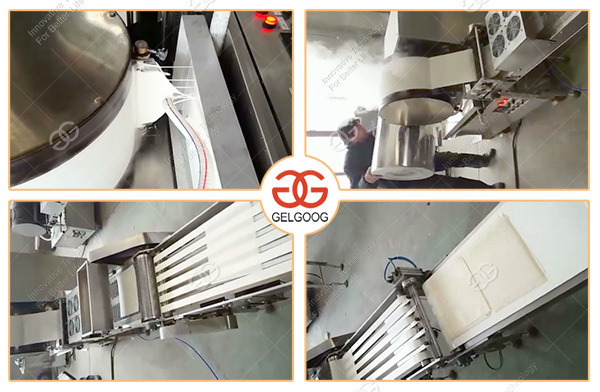

This machine is multi-functional automatic integration of production equipment, simple operation, high automation, and one person can produce imitation of hand pastry, egg dumpling skin, duck pie, spring roll wrapper, crepe, lumpia wrapper, etc.

Advantage Spring Roll Wrapper Machine:

1. Production of product size, thickness, crisp, moisture, softness, hardness, can be controlled

2. Machine is full automatic, just need one worker, saving labor

3. Machine is made of stainless steel materaial, safe and easy to clean

4. Size of spring roll wrapper can be customized according to requirement

Structure Introduction Spring Roll Wrapper Machine:

Composed of mixer, automatic batter feeding part, heating&shaping cylinder, cutter, conveying & cooling part and sheet stacking parts, series spring roll sheet machines can make injeras in either round or rectangular shapes.

If you want the whole processing line, it include the following main parts:

1. Mixing System

2. Paste Feeding System

3. Heating and molding machine.

4. Heating Chunking

5. Cutting Parts

6. Conveying Parts

7. Cooling System

8. Sheet Stacking Syste

|

Model |

GGSR-3620 |

GGSR-5029 |

GGSR-8045 |

|

Dia. of heating Cylinder |

360mm |

500mm |

800mm |

|

Size of machine |

4.3*0.8*1.35 |

4.7*0.95*1.58m |

5.2*1*1.5m( |

|

Electric Power |

6.0kw or gas |

13.2KW or gas |

38kw or gas |

|

Host Power |

0.75KW |

0.75KW |

0.75KW |

|

Power Cutter |

0.55KW |

0.55KW |

0.55KW |

|

Belt Power |

0.55KW |

0.55KW |

0.55KW |

|

N. W. |

320kg |

800kg |

1000Kg |

|

Size of the sheet ( Max.) |

Round dia: 180mm Rectangular:200mm |

Round dia:280mm Rectangular:290mm |

Round dia:430mm Rectangular:450mm |

|

Thickness of the sheet |

0.3-2.0mm |

0.3-2.0 mm |

0.3-2.0 mm |

|

Production capacity |

800pcs/h |

1500-2000pcs/h |

4000pcs/h |

1. All the machine parts are put in strong woody crates firstly, then place into the containers if necessary. The employees are always grave and expert as soon as they are dealling with the containers, ensure our cilents could see their procuts safely.

2. We can ship the machine by sea, express and air

1. Ask:What is your guarantee of machine ?

Answer: Usually our guarantee is 1 years. But if you have any questions when using the machine, you can take pictures or videos to us, we have the engineer to help you solve the problems. Any questions we will be here!

2. Ask:About the machine voltage or power of machine ?

Answer: Usually in our country is 220v,50hz, single phase , or 380v, 50hz, 3 phase .if you have the special requirement , pls tell us, we will vetify the voltage according to your requirement.

3. Ask:how to install the machine ?

Answer: We can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you to install it in your country .

If you have other question need us to answer, pls feel free to send inquiry or message!