- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.2

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

EENOR

-

Voltage:

-

220-440V

-

Year:

-

2024

-

Power (kW):

-

2.2-15

-

Weight (KG):

-

2300 KG

-

Market:

-

Asia,Africa,South and north of America,East of Europe

-

Working diameter of rolls:

-

160-660 mm

-

Working length of rolls:

-

320-2130 mm

-

Working linear speed of front roll:

-

8.95-28.6 m/min

-

Max.gap:

-

4.5-15 mm

-

Capacity per.batch:

-

1-165 kg

-

Driving motor power:

-

5.5-245 kw

-

Series:

-

banbury mixer

Quick Details

-

Diameter of Roll(mm):

-

560 mm

-

Rotation Speed of Front Roll(rpm):

-

20 - 200 rpm

-

Length of Roll(mm):

-

1530 mm

-

Roll Ratio(Front/Back):

-

1:1.2

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

EENOR

-

Voltage:

-

220-440V

-

Year:

-

2024

-

Power (kW):

-

2.2-15

-

Weight (KG):

-

2300 KG

-

Market:

-

Asia,Africa,South and north of America,East of Europe

-

Working diameter of rolls:

-

160-660 mm

-

Working length of rolls:

-

320-2130 mm

-

Working linear speed of front roll:

-

8.95-28.6 m/min

-

Max.gap:

-

4.5-15 mm

-

Capacity per.batch:

-

1-165 kg

-

Driving motor power:

-

5.5-245 kw

-

Series:

-

banbury mixer

Details of machine:

2.spiral angle and over lapping length of the blades of the rotors are of reasonable design and make the materials to bedispersed uniformly.

3.surface where is contracted with the machine are all plated with hard chromium and polished, which is corrosion-resistantand wear-resistant.

4. jacket construction is adopted in parts that surfaces contactwith materials to achieve excellent water-cooling or steamheating effect and fit in with the needs of plastics and rubberprocessing technology.

5. feeding from back door on the frame(or separate top door) is convenient ofr continuous process operation in aproduction line. The mixing chamber is able to turn forward by 140 around th front rotors to discharge and is easy for changing pigments and cleaning the chamber.

6. programmable logic controller(PLC) is adopted in theelectric-control system, which has reliable control function andalarm function, and interlock safety-protection function and it is provided with serial interface of net.

Technical Parameters:

|

Type |

XK-150 |

XK-250 |

XK-300 |

XK-360 |

X(S)K-400 |

X(S)K-450 |

X(S)K-560 |

|

Working diameter of rollers(mm) |

150 |

250 |

300 |

360 |

400 |

450 |

560 |

|

Working lengh of rollers(mm) |

280 |

620 |

750 |

900 |

1000 |

1200 |

1530 |

|

Working linear speed |

8 |

15.1 |

15.1 |

16.25 |

18.65 |

24.5 |

27.7 |

|

of front roller(m/min) |

|||||||

|

Friction ratio of front |

1:1.4 |

1:1.17 |

1:1.27 |

1:1.25 |

1:1.27 |

1:1.27 |

1:1.12 |

|

and rear roller(m/min) |

|||||||

|

Maximum roll distance(mm) |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

Per feeding quantity(kg) |

1-2 |

10-15 |

15-20 |

20-25 |

10-35 |

25-50 |

50-65 |

|

Drive motor power(kw) |

7.5 |

18.5 |

22 |

30 |

37 |

55 |

95 |

|

Overall size(L×W×H)(mm) |

1080 |

3400 |

3580 |

3940 |

42580 |

5200 |

6120 |

|

796 |

1350 |

1550 |

1780 |

1850 |

2380 |

2280 |

|

|

1415 |

1500 |

1695 |

1740 |

1870 |

1770 |

1000 |

|

|

Weight(kg) |

1100 |

3500 |

5205 |

5670 |

7600 |

13000 |

22000 |

|

Notes |

Bearing transmission |

Nylon bush:dry oil lubrication;

|

Nylon bush: |

||||

|

Steel tile:thin oil lubrication |

dry oil lubrication |

||||||

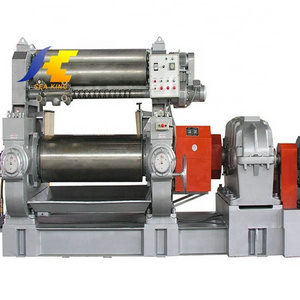

Pictures of machine:

Banbury Mixing Mill / Rubber Mixer

We can product all kinds of non-standard rubber machinery,we can design by your requests.

If you are interested in our products or have any questions please contact us freely.We will try our best to meet your requirement at first time.

(1)Train how to operate and maintain the equipment, we can also offer a house call to install and debugging.

(2)Provide the formers of many specifications, and we can make according to your demand.

(3)Guarantee to keep the machine in good repair.

1.Q:Are you a factory or trading company?

A:We are factory,passed CE,BV certification.

2.Q:Where is your factory?How can i visit ?

A:Our factory located in qingdao city.You can fly to qingdao liuting airport,then we can pick you up to our facotry to visit.Warm welcome visit us.

3.Q:How does your factory control the quality of machines and after sales service?

A:Our machines passed CE,BV,ISO,SGS certification,pls confirm the quality.All our machines have 1 year guarantee, will provide lifetime maintenance.