- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 50HZ(can be customized)

-

Place of Origin:

-

Henan, China

-

Dimension(L*W*H):

-

2050*680*1450mm

-

Weight:

-

185 KG

-

Machinery Capacity:

-

80-280pcs/min(base on products and labels size)

-

Product name:

-

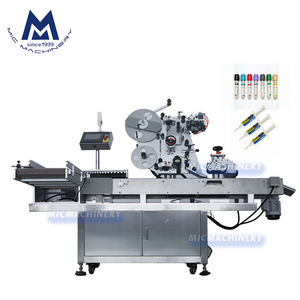

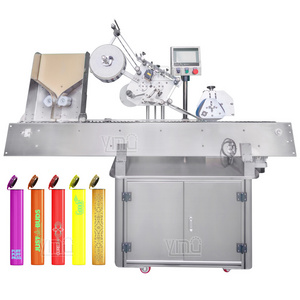

CGMP Requirements Ampoule Vial Labeling Machine

-

Function:

-

Auto Sticker Labeling Equipment

-

Label material:

-

Sticker Laber

-

Label accuracy:

-

Within +/-1.0mm

-

Labeling speed:

-

80-280Pcs/min

-

Labeling type:

-

Round Bottle Labeling Machine

-

Label size(customizable):

-

Length: 20mm~285mm Width (backing paper width): 20mm~175mm

-

Application industry:

-

COSTMETIC, food, daily chemical, wine and other industries

-

Product size(customizable):

-

Diameter: 25mm~100mm Height: 25mm~300mm (product size and shape ratio)

Quick Details

-

Application:

-

Beverage, Chemical, Commodity, Food, cosmetic

-

Packaging Type:

-

case

-

Packaging Material:

-

Wood

-

Voltage:

-

220V, 50HZ(can be customized)

-

Place of Origin:

-

Henan, China

-

Dimension(L*W*H):

-

2050*680*1450mm

-

Weight:

-

185 KG

-

Machinery Capacity:

-

80-280pcs/min(base on products and labels size)

-

Product name:

-

CGMP Requirements Ampoule Vial Labeling Machine

-

Function:

-

Auto Sticker Labeling Equipment

-

Label material:

-

Sticker Laber

-

Label accuracy:

-

Within +/-1.0mm

-

Labeling speed:

-

80-280Pcs/min

-

Labeling type:

-

Round Bottle Labeling Machine

-

Label size(customizable):

-

Length: 20mm~285mm Width (backing paper width): 20mm~175mm

-

Application industry:

-

COSTMETIC, food, daily chemical, wine and other industries

-

Product size(customizable):

-

Diameter: 25mm~100mm Height: 25mm~300mm (product size and shape ratio)

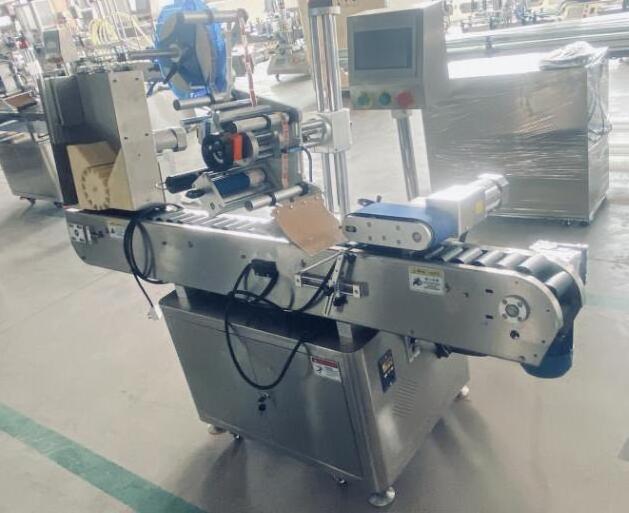

Product Description

This l

abeling machine

is suitable for circular and semicircular labeling of unstable cylindrical objects. It adopts horizontal transmission and horizontal labeling to increase stability and improve labeling efficiency. Equipped with an automatic bottle dividing mechanism, it can save more labor and increase labeling standard efficiency.

It can be equipped with a printer or an inkjet printer to the labeling head, which can print information such as production date, batch number and inkjet barcode on the label.

Optional inkjet printer to conveyor belt can be used to print production date, batch number, barcode and other information on the product before or after labeling.

It can be equipped with a printer or an inkjet printer to the labeling head, which can print information such as production date, batch number and inkjet barcode on the label.

Optional inkjet printer to conveyor belt can be used to print production date, batch number, barcode and other information on the product before or after labeling.

Optional functions:

① Hot coding/printing function;

②Automatic material receiving function (considered with the product);

③ Automatic feeding function (customized according to customer requirements).

① Hot coding/printing function;

②Automatic material receiving function (considered with the product);

③ Automatic feeding function (customized according to customer requirements).

Analysis of the labeling process:

Put the product (in the blanking box) ->separate the product and spread it out to the middle of the conveyor chain roller -> product conveying -> product inspection ->labeling ->collect the labelled products.

◆

Applicable products:

small products that require labels or films to be attached to the circumferential surface or small conical surface.

◆ Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

◆ Application industry: widely used in cosmetics, electronics, hardware, plastic and other industries.

◆ Application examples: solid plastic bottle labeling, oral liquid bottle labeling, pen labeling, lipstick labeling chewing gum, moxa sticks, sausages, etc.

◆ Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

◆ Application industry: widely used in cosmetics, electronics, hardware, plastic and other industries.

◆ Application examples: solid plastic bottle labeling, oral liquid bottle labeling, pen labeling, lipstick labeling chewing gum, moxa sticks, sausages, etc.

◆ High speed, using side horizontal roller conveying mechanism, the conveying chain is

inclined, the bottle is automatically guided, and the conveying and labeling are stable. The labeling speed is up to 400bottles/min, saving a lot of manpower and material resources;

◆ Low bottle breaking rate, using flexible bottle dividing technology and flexible labeling technology, the bottle separation and labeling are smooth, and the broken bottle rate is less than 1 in 100,000;

◆ The labeling quality is excellent, using the tape detouring correction technology, the label head and tail are highly overlapped; the rolling type labeling, the labeling is flat, no wrinkles, no bubbles, and the packaging quality is improved;

◆ High stability, advanced electronic control system composed of Panasonic PLC + Weilun touch screen + Panasonic needle-shaped electric eye + German Sick label electric eye, which supports 7×24-hour operation of the equipment;

◆Intelligent control, automatic photoelectric tracking, with no labeling, labelless automatic correction and label automatic detection function, to prevent missing stickers and label waste;

◆ Sturdy and hygienic, mainly made of stainless steel and high-grade aluminum alloy, in line with GMP production specifications, firm structure, beautiful and generous;

◆ With fault alarm function, production count function, power saving function, production number setting prompt function,parameter setting protection function, convenient production management;

inclined, the bottle is automatically guided, and the conveying and labeling are stable. The labeling speed is up to 400bottles/min, saving a lot of manpower and material resources;

◆ Low bottle breaking rate, using flexible bottle dividing technology and flexible labeling technology, the bottle separation and labeling are smooth, and the broken bottle rate is less than 1 in 100,000;

◆ The labeling quality is excellent, using the tape detouring correction technology, the label head and tail are highly overlapped; the rolling type labeling, the labeling is flat, no wrinkles, no bubbles, and the packaging quality is improved;

◆ High stability, advanced electronic control system composed of Panasonic PLC + Weilun touch screen + Panasonic needle-shaped electric eye + German Sick label electric eye, which supports 7×24-hour operation of the equipment;

◆Intelligent control, automatic photoelectric tracking, with no labeling, labelless automatic correction and label automatic detection function, to prevent missing stickers and label waste;

◆ Sturdy and hygienic, mainly made of stainless steel and high-grade aluminum alloy, in line with GMP production specifications, firm structure, beautiful and generous;

◆ With fault alarm function, production count function, power saving function, production number setting prompt function,parameter setting protection function, convenient production management;

Specification

|

item

|

value

|

|

Type

|

LABELING MACHINE

|

|

Applicable Industries

|

Manufacturing Plant, Restaurant, Retail, Food & Beverage Shops, Other

|

|

Showroom Location

|

None

|

|

Condition

|

New

|

|

Application

|

Beverage, Chemical, Commodity, Food

|

|

Packaging Type

|

Bottles, jar, can, pail, tube, vails etc.

|

|

Packaging Material

|

Plastic, glass, etc.

|

|

Automatic Grade

|

Automatic

|

|

Driven Type

|

Electric

|

|

Voltage

|

220V, 50HZ(can be customized)

|

|

Place of Origin

|

China

|

|

|

Henan

|

|

Dimension(L*W*H)

|

2050mm×650mm×1450mm

|

|

Weight

|

185KG

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Long Service Life

|

|

Machinery Capacity

|

80-280pcs/min(base on products and labels size)

|

|

Marketing Type

|

New Product 2020

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Other, Motor

|

|

Product name

|

Round Bottle Labeling Machine

|

|

Function

|

Auto Sticker Labeling Equipment

|

|

Label material

|

Sticker Laber

|

|

Label accuracy

|

Within +/-1.0mm

|

|

Label size(customizable)

|

Length: 20mm~100mm; Width (backing paper width): 20mm~130mm

|

|

Application industry

|

food, daily chemical, wine and other industries

|

|

Product size(customizable)

|

For round bottle: diameter: 10mm~30mm

|

Customer Comments

Hot Searches