- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

VKSELE

-

Model Number:

-

TPS-2D

-

Max. Current:

-

0

-

Product name:

-

Run-off switch

-

Model:

-

TPS-2D

-

Humidity:

-

≤85%

-

Action angle:

-

30°

-

Limit angle:

-

70°

-

Ambient temperature::

-

-30~+60℃

-

Switch potency:

-

AC/DC24-380V

-

Action force:

-

10kg

-

Protect class:

-

IP65

-

Warranty:

-

1 Year

-

Certification:

-

ce

Quick Details

-

Whether the smart:

-

NO

-

Max. Voltage:

-

24-380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

VKSELE

-

Model Number:

-

TPS-2D

-

Max. Current:

-

0

-

Product name:

-

Run-off switch

-

Model:

-

TPS-2D

-

Humidity:

-

≤85%

-

Action angle:

-

30°

-

Limit angle:

-

70°

-

Ambient temperature::

-

-30~+60℃

-

Switch potency:

-

AC/DC24-380V

-

Action force:

-

10kg

-

Protect class:

-

IP65

-

Warranty:

-

1 Year

-

Certification:

-

ce

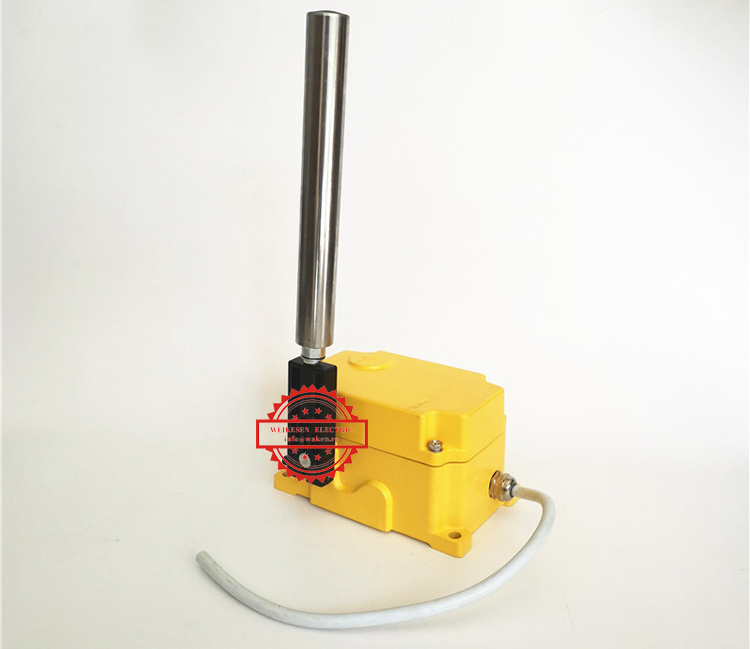

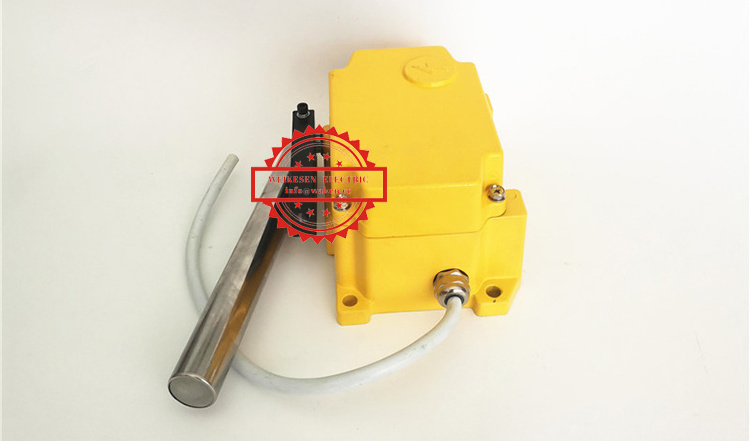

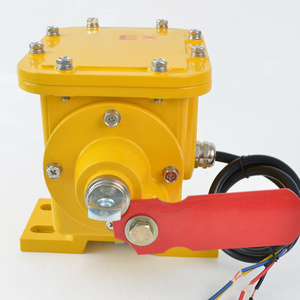

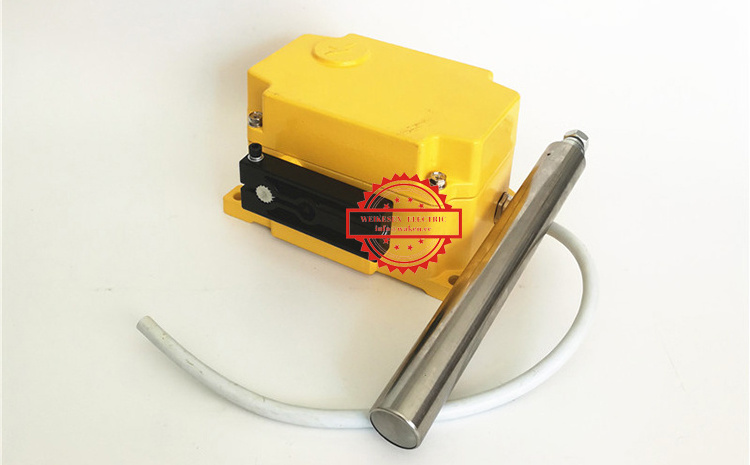

Overview:

The two-way run-off switch is used for detecting the runout of the conveyor tape and is widely used in mines, electric power and chemical plants and mines with belt conveyors. The product is installed on both sides of the tape conveyor to prevent the material from overflowing due to the tape deviation. It is a kind of protection switch used for the emergency stop of the tape conveyor, and pulling the wire rope at any point within the operating distance of the switch will cut off the running circuit to stop the whole line and realize the protection of the tape machine and personal safety.

Working principle :

When an emergency occurs at the tape transport site, pull the wire rope tied to the lugs to make the slider in

the machine act with the switch to signal a stop. Release the wire rope and pres s the reset bar to reset.

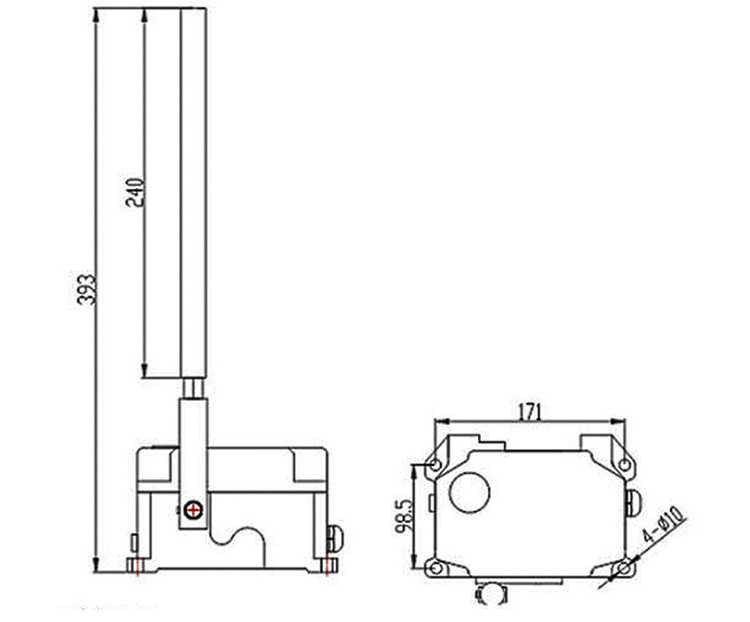

Product Parameters :

|

Product Name |

Square Run-off switch |

Model |

TPS-2D/ROS-2D |

|

Belt Speeds |

<6.35S |

Environmental Temperature |

-30℃--- +60℃ |

|

Relative Humidity |

less than 85% |

Contact Capacity |

AC/DC24-380V |

|

Extreme Angle |

70° |

Movement Power |

10kg |

|

Reliability |

>10000000 times |

Protection Level |

NEMA4 |

|

Current |

1-5A |

Alarm Angle |

Adjustable at 22.5° off vertical |

Structure characteristics:

The universal mounting design allows the deflection switch to be mounted on the top or bottom of the conveyor beam at will. Rugged cast aluminum enclosure, NEMA 4 rated, with special finishes available for special environments. Integral cover plate is easy to wire and adjust, and can be removed without removing the action bar. The action rod bearing speed is rated at 5000 rpm, suitable for belt speed less than 6.35/sec. The action rod normal angle adjustment range is 22.5° adjustable. The alarm contact is activated when the normal angle is 10°. When the normal clamping angle is 10°, the alarm contact will be activated, and when the normal clamping angle is 30°, the stop contact will be activated.

Installation And Use:

The run-off switch can be fixed at the top or bottom of the longitudinal beam of the conveyor, and the action rod is about 25mm from the edge of the tape. When the running tape is deflected, the edge of the tape drives the stick to rotate and squeeze to make it tilt, if the stick tilts more than the first action angle, the switch issues a set of switch signals, if the stick continues to tilt more than the second action angle, it outputs another set of switch signals. The two sets of switch signals can be used for alarm or stop respectively. After the tape machine is reset to normal operation, the vertical stick will be reset automatically.

Applicable Places:

Various belt conveyors, port handling systems, crane/excavator lifting arm limit, Heavy-duty limit switches.

Special option stainless steel cover screw stainless steel action rod and Stainless steel trolley with optional

mounting bracket to increase the number of switch points.

Product Display: