- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CN-SSY-9

-

Brand:

-

CN-SSY

-

Size:

-

Customizable

-

MOQ:

-

1 Pcs

-

Certification:

-

SSY

Quick Details

-

Warranty:

-

1years

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

CN-SSY

-

Model Number:

-

CN-SSY-9

-

Brand:

-

CN-SSY

-

Size:

-

Customizable

-

MOQ:

-

1 Pcs

-

Certification:

-

SSY

We specialize in CNC machining ( Turning and Milling ) and sheet metal machining services. Here is our introduction for your reference.

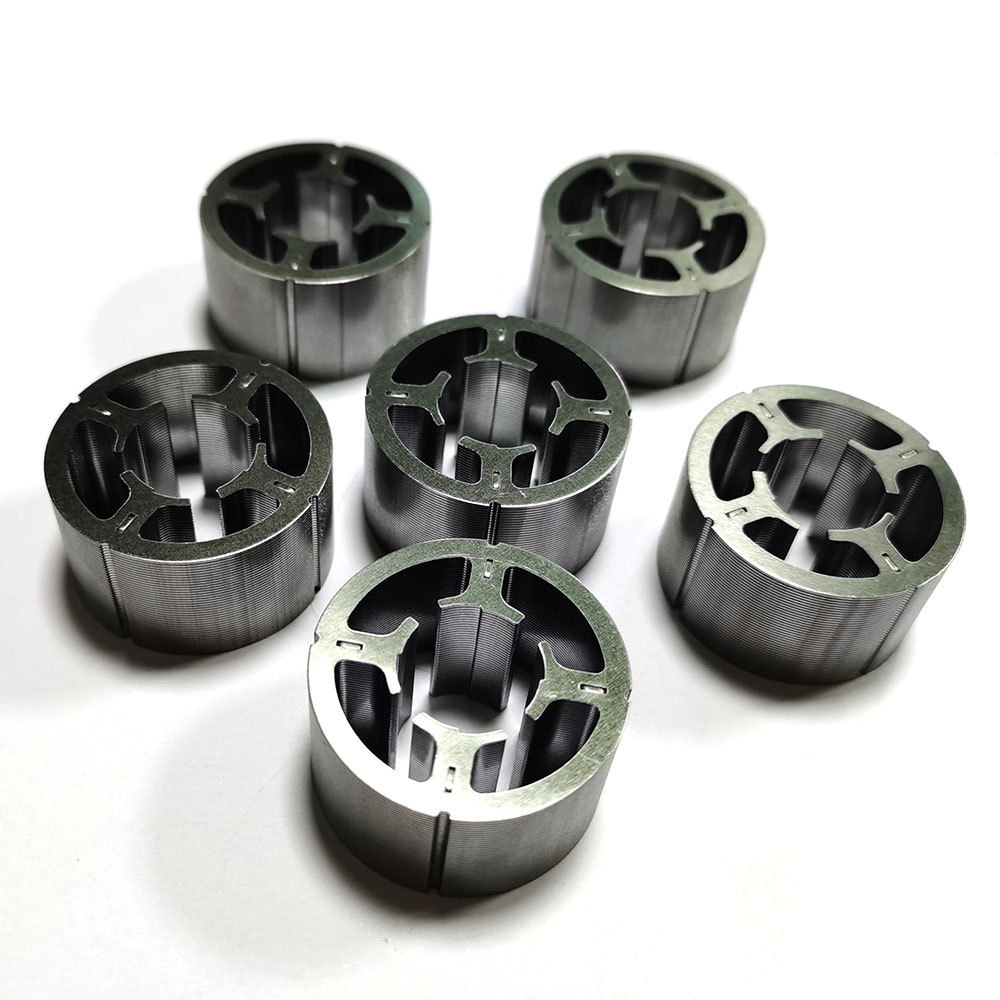

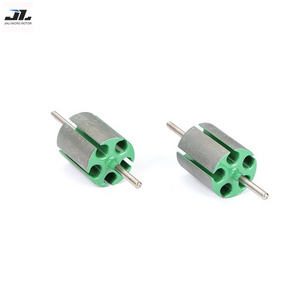

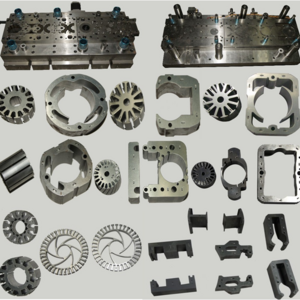

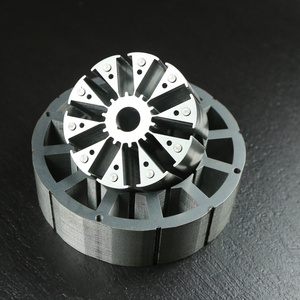

Products Description

|

Quality Assurance

|

ISO9001:2015 Certified

|

|

|

|

|||

|

Machining Equipment

|

CNC Machining Center /Composite CNC Machine / CNC Lathes / Grinding Machines / Milling Machines / Wire-cuts / Laser Cuts / CNC Shearing Machines / CNC Bending Machines /CNC Stamping Machines etc.

|

|

|

|

|||

|

Materials

|

Aluminum Alloy: 6061/ 6063 / 7075 /5052 ADC12/518 etc.

Brass Alloy: H59 / H62 / H64/ 3602 / 2604 / etc.

Stainless Steel Alloy: 316L / 304 / 316 / 412 / etc.

Steel Alloy: Carbon Steel / Die Steel / Spring Steel etc.

Other Special Materials: Titanium/ Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK etc.

We handle many other type of materials. Please contact us if your required material is not listed above.

|

|

|

|

|||

|

Surface Treatment

|

Plating, Brushing,Polishing,Sandblasting,Anodizing,Pickling&Passivation, Vibration,PVD, Nickel Plating,tinting etc.

|

|

|

|

|||

|

Inspection

|

Three-coordinate measuring machine /Mitutoyo Tool Microscope can measure up to 300mmX x 175mmY x 220mmZ

|

|

|

|

|||

|

File Formats

|

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,IGS , STP etc.

|

|

|

|

|||

About Us

SSY ( Xiamen ) Hardware Products Co. , Ltd. was founded in 2015 . The core technicians began to work in design and machining in 1992 . SSY is committed to customized high-precision CNC turning and milling processing . The company has imported turning and milling equipment from Switzerland( TORNOS ) , precision carving drilling and tapping machine , wire cutting and other equipment . Our machining accuracy can reach 0.005mm tolerance , which provides a strong guarantee for precision parts processing . We always strive to exceed customers expectations in all aspects of the product manufacturing process , and recognize our great responsibility to customers , employees , suppliers and society . Our goal is to provide every customer with reliable , feasible and economical CNC parts and fast sample service industry . Based on our precision processing , competitive cost and satisfactory customer service , we can OEM products according to the specific needs of customers . At the same time , we are conscientiously responsible for the quality control from IQC to OQC,throughout every link of production , and do our best to do a good job in quality and service.

Certificates

We feature an experienced engineering team system that is adaptable enough to cater for one-off prototypes through to production in volume.

Product packaging

we will shipping according to your requirement.

Than,we will choose better shipping way for you if you need. We provide multi shipping method, such as shipping by air, by express, by train, by sea.

FAQ

Q1: Where can I get product & price information?

A1: Send us an inquiry e-mail, we will contact you as we receive your mail.

Q2: What's kinds of information you need for a quote?

A2: Kindly please provide the product drawing in PDF, and will be better youcan provide in STEP or IGS.

Q3:No drawings to quote?

A3:Of course, we are glad to receive your samples, pictures or detailed size of the draft in order to accurately quote.

Q4. Can we get some samples before mass production?

A4: Absolutely

A4: Absolutely

Q5: How to deliver the goods?

A5: We deliver the products by Alibaba transportation.

Q6:How about the lead time?

A6:Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q7:Proper suggestions

A7:If you are not familiar with material,surface treatment or something,please tell us your requirement,according to which we will provide suggestions. Also,advice will be given during machining when your design is found not good enough. Anyway, it is finally up to you whether to adopt the suggestions.

Q8:Lower cost in machining hardended metal

A8:We

've found our way to slow the damage of tool during machining hardended metal, and as a result, the cost decreases.

Q9:Good after sales services

A9:If,unexpectedly,the goods are not meet the requires, we will provide you with solutions or take yours into consideration.

Production Machinery

|

Equipment name

|

brand

|

quantity

|

Number of Year(s) Used

|

|||

|

Swiss automatic lathe

|

TORNOS/STAR

|

20

|

1.0

|

|||

|

Machining center

|

Haas / yongyuchang

|

14

|

1.5

|

|||

|

CNC lathe

|

Baoji

|

8

|

2.0

|

|||

|

Grinder / wire cutter

|

-

|

10

|

2.0

|

|||

|

Testing equipment

|

|

|

|

|||

|

Quadratic element

|

HIKSFON

|

1

|

2.0

|

|||

|

Image Measuring Instrument

|

HIKSFON

|

1

|

0.5

|

|||

|

Roughness meter / roundness meter

|

HIKSFON

|

2

|

2.0

|

|||

Hot Searches