# HD LCD display, with both Chinese and English language options, a display programming parameters, faster and more convenient programming.

# Backgauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device.

# Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2600 mm

-

Backgauge Travel (mm):

-

0 - 550 mm

-

Throat Depth (mm):

-

6 mm

-

Brand Name:

-

DURMAPRESS

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

3600 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2320x1420x1500mm, 2320x1420x1500mm

-

Year:

-

2023

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Shearing Machine

-

Application:

-

Metal Sheet Cutting

-

Cutting material:

-

Stainless Steel

-

Control system:

-

E21S

-

Cutting thickness:

-

4mm

-

Cutting length:

-

2500mm

-

Nominal pressure:

-

31.5Mpa

-

Weight:

-

3600 KG

Quick Details

-

Max. Cutting Width (mm):

-

2500

-

Max. Cutting Thickness (mm):

-

4 mm

-

Shearing Angle:

-

1°30, 1'30

-

Blade Length (mm):

-

2600 mm

-

Backgauge Travel (mm):

-

0 - 550 mm

-

Throat Depth (mm):

-

6 mm

-

Brand Name:

-

DURMAPRESS

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

3600 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2320x1420x1500mm, 2320x1420x1500mm

-

Year:

-

2023

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Shearing Machine

-

Application:

-

Metal Sheet Cutting

-

Cutting material:

-

Stainless Steel

-

Control system:

-

E21S

-

Cutting thickness:

-

4mm

-

Cutting length:

-

2500mm

-

Nominal pressure:

-

31.5Mpa

-

Weight:

-

3600 KG

Product Description

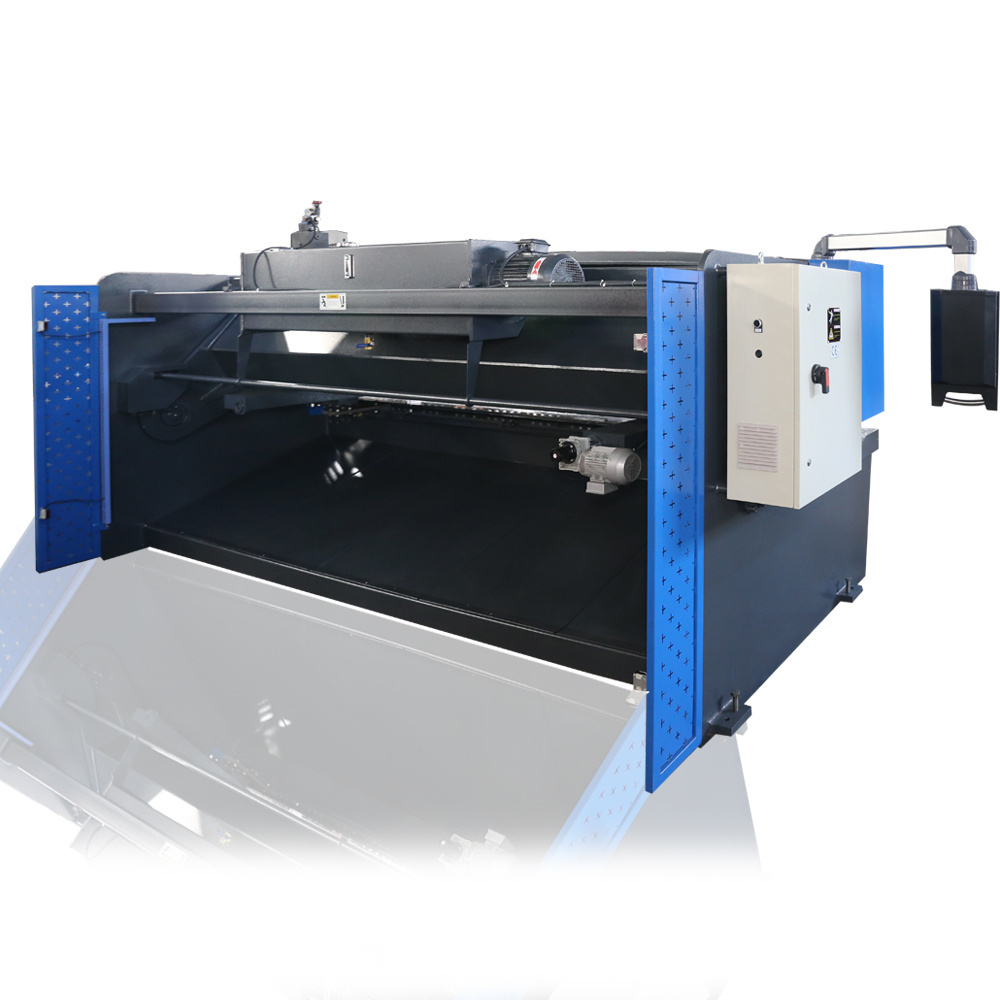

NC hydraulic swing beam type shear machine for metal sheet cutting

Performance characteristic Hydraulic transmission, pendulum-type tool holder. The overall welding of the frame is hard and durable, and the use of a nitrogen cylinder returns smoothly and rapidly.

It has the function of stepless adjustment stroke. The amount of upper and lower blade edge clearance is adjusted by the handle, and the gap of the blade is even and rapid.NC control system and position encoder, inverter, closed-loop control system, speed, high positioning accuracy, good stability, can accurately ensure the accuracy of the back gauge displacement size, while the CNC system has precision compensation and automatic detection A variety of additional features.

It has the function of stepless adjustment stroke. The amount of upper and lower blade edge clearance is adjusted by the handle, and the gap of the blade is even and rapid.NC control system and position encoder, inverter, closed-loop control system, speed, high positioning accuracy, good stability, can accurately ensure the accuracy of the back gauge displacement size, while the CNC system has precision compensation and automatic detection A variety of additional features.

STANDARD EQUIPMENTS

√ Hardened blades.

- Top blades : 2 sides

- Bottom blades : 4 sides

√ E21S controller.

√ 250mm throat depth.

√ 600mm motorized backgauge system with 0,1 mm accuracy.

√ 800mm side gauge and front support arms.

√ Metric and inch rulers.

√ Front, side and back safety panels which are suitable for CE norms.

√ Sheet sliding system.

√ Schneider Electric System.

√ Rexroth hydraulic system.

√ Hold down cylinders.

√ Moveable foot pedal.

√ Manual blade gap adjustment.

√ Emergency stop button.

√ Collapsible finger protection.

- Top blades : 2 sides

- Bottom blades : 4 sides

√ E21S controller.

√ 250mm throat depth.

√ 600mm motorized backgauge system with 0,1 mm accuracy.

√ 800mm side gauge and front support arms.

√ Metric and inch rulers.

√ Front, side and back safety panels which are suitable for CE norms.

√ Sheet sliding system.

√ Schneider Electric System.

√ Rexroth hydraulic system.

√ Hold down cylinders.

√ Moveable foot pedal.

√ Manual blade gap adjustment.

√ Emergency stop button.

√ Collapsible finger protection.

Specification

E21S controlle Features

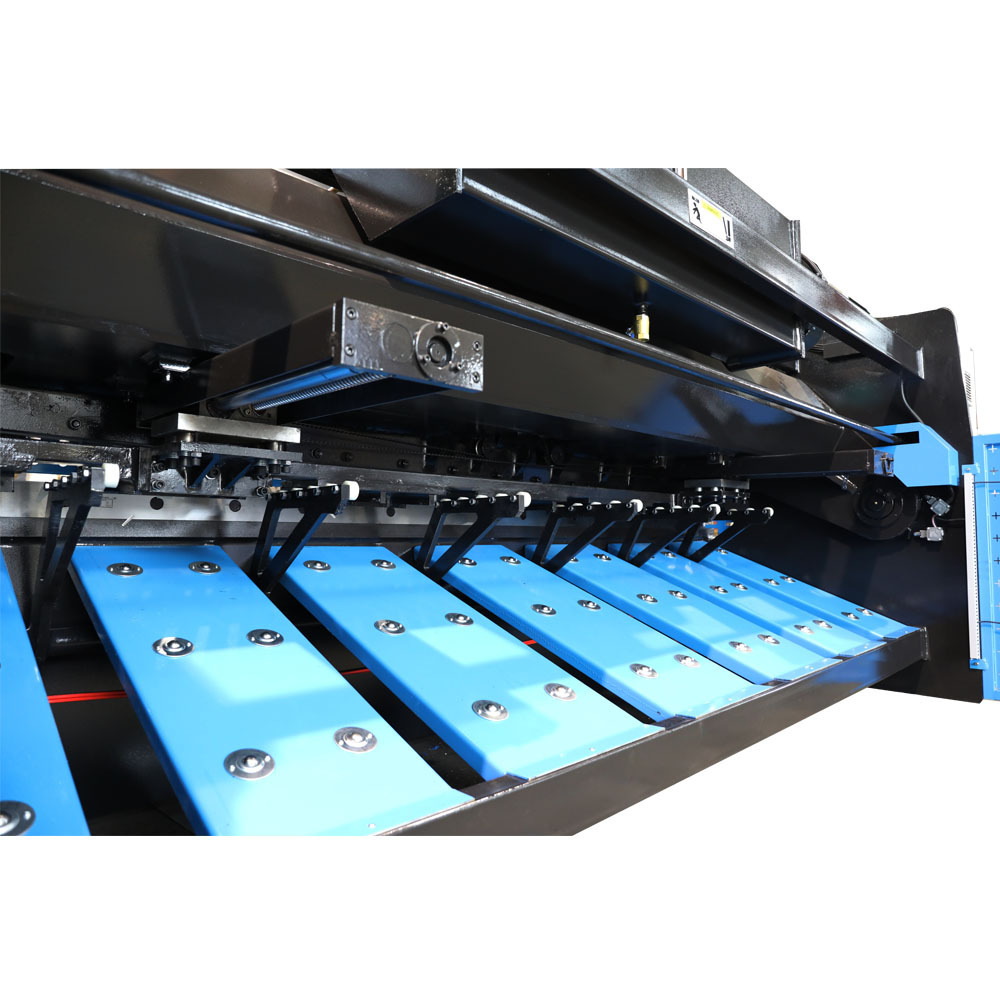

Hydraulic Hold -down pads

The lower end of press cylinder is made of non -material , which has certain elasticity and large friction coefficient. when

cutting the sheet , the press pad can be in close contact with material plate to provide sufficient friction to effectively

prevent the plate from being shaken during the shearing process.

cutting the sheet , the press pad can be in close contact with material plate to provide sufficient friction to effectively

prevent the plate from being shaken during the shearing process.

Simens motor

Germany famous brand motor improves the lifespan of the machine and keeps the machine and keeps the machine working in low noise

environment.

environment.

Germany EMB Casing Tube

The EMB Casing Tube and connectors effectively reduce the adds againest welding slag jaming the valves and affect oil flowing

|

Model

|

QC12Y-4x2500

|

|

Cutting thickness

|

4mm

|

|

Cutting length

|

2500mm

|

|

Cutting angle

|

1°30´

|

|

Material strength

|

450N/mm²

|

|

Number of strokes

|

8-14Hits/min

|

|

Power

|

5.5Kw

|

|

Dimension

|

2820x1520x1850mm

|

|

Wight

|

3600kg

|

Hot Searches