- Product Details

- {{item.text}}

Quick Details

-

Product type:

-

Servo Valve

-

Material:

-

Cast steel

-

Drive way:

-

Electro-hydraulic

-

Scope of application:

-

Industrial field

-

Series:

-

0062

-

Condition:

-

New

-

Type:

-

Fittings

-

Order number:

-

H40DAGM4NAH

Quick Details

-

Place of Origin:

-

America

-

Brand Name:

-

Moog

-

Model Number:

-

0062-191C

-

Product type:

-

Servo Valve

-

Material:

-

Cast steel

-

Drive way:

-

Electro-hydraulic

-

Scope of application:

-

Industrial field

-

Series:

-

0062

-

Condition:

-

New

-

Type:

-

Fittings

-

Order number:

-

H40DAGM4NAH

Product Description

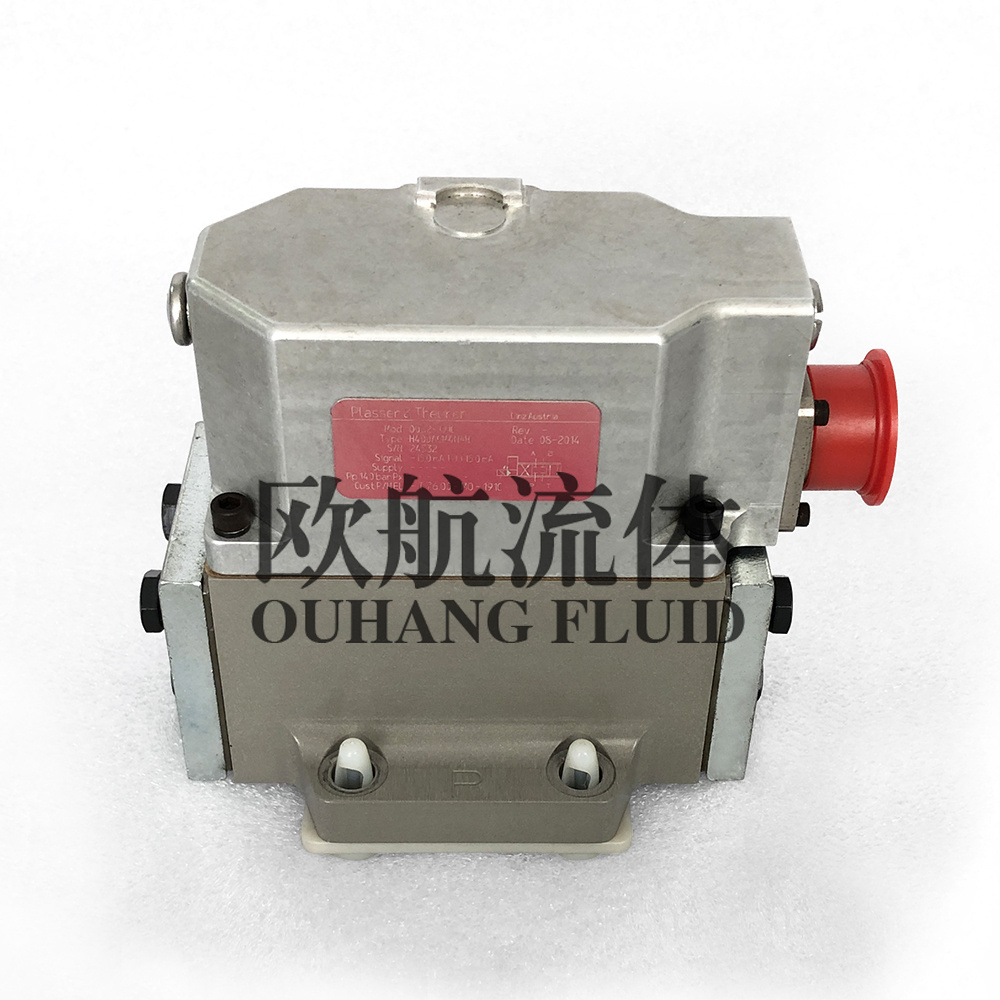

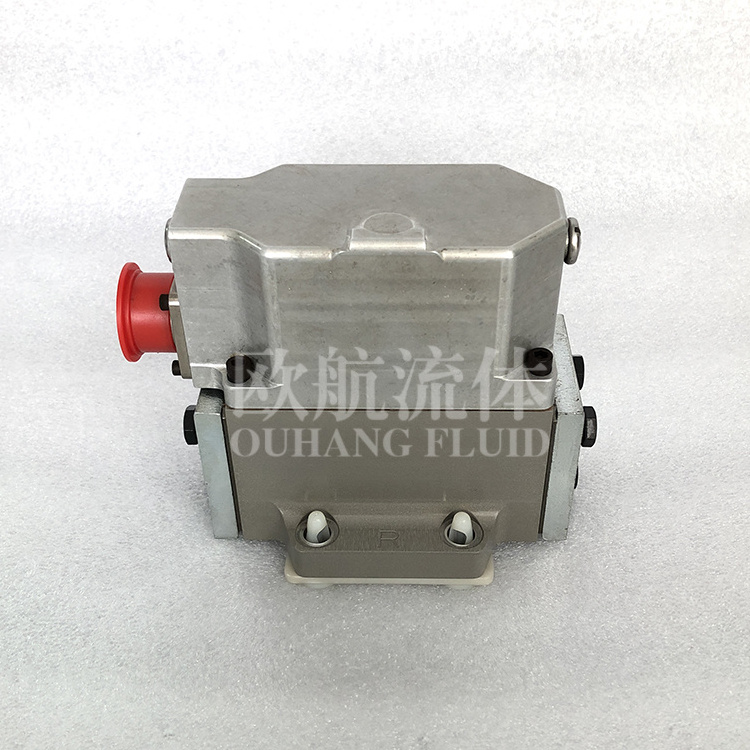

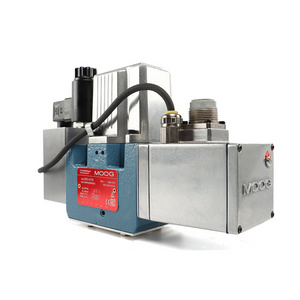

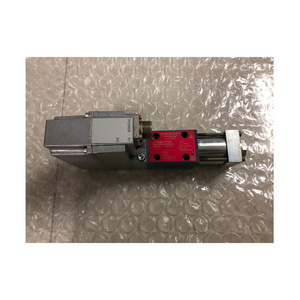

The 0062 Series flow control servovalves are throttle valves for 3 and preferably 4-way applications. They are a high performance, 2-stage design that covers the range of rated flows from 4 to 63 l/min (1 to 16.5 gpm) at 35 bar (500 psi) valve pressure drop per spool land. The output stage is a closed center, four-way sliding spool. The pilot stage is a symmetrical double-nozzle and flapper, driven by a double air gap, dry torque motor. Mechanical feedback of spool position is provided by a cantilever spring. The valve design is simple and rugged for dependable, long life operation.

The design is simple and rugged for dependable, long life operation. The output stage is a closed center, 4 way sliding spool. The pilot stage is comprised of a symmetrical, double nozzle dry torque motor. The 2nd stage spool position is controlled by a carbide tipped feedback wire. The carbide ball on the end of the feedback wire is a mandatory design requirement that ensures high accuracy, reliable operation and long service life. All of our servo valves are known for high accuracy and reliable operation even in the harshest industrial applications. These valves are suitable for electrohydraulic position, speed, pressure or force control systems with high dynamic response requirements.

Technical Parameters

|

Specifications

|

|

|

|

Hydraulic Data

|

|

|

|

Rated Flow*

|

10 to 75 l/min (2.5 to 20 gpm)

|

|

|

Standard Configurations

|

10, 20, 40, 60, 75 l/min

|

|

|

|

(2.5, 5, 10, 15, 20 gpm)

|

|

|

Max. Operating Pressure

|

210 bar (3,000 psi)

|

|

|

Performance Data

|

|

|

|

100% Step Response**

|

40 ms

|

|

|

Frequency Response***

|

60 Hz

|

|

|

Electrical Data

|

|

|

|

Rated Signal****

|

15 to 100 mA

|

|

|

Standard Configurations

|

30, 100 mA

|

|

|

Physical Data

|

|

|

|

Size

|

Size 04 (ISO 10372-04-04-0-92)

|

|

|

(Mounting Pattern)

|

|

|

|

Weight

|

1.22 kg (2.7 lbs)

|

|

|

Additional Options

|

Contact Industrial Application Engineering for additional Flow, Pressure and other options

|

|

Related Products

Packing&Shipping

In order to ensure that the product is not damaged during transportation, we will choose to use high-hardness cardboard boxes or wooden boxes to package the product according to the volume of the product, and adopt protective measures such as foam anti-collision and wooden frame fixing to ensure the safe and non-destructive delivery of the goods to the greatest extent.

Company Introduction

contact us

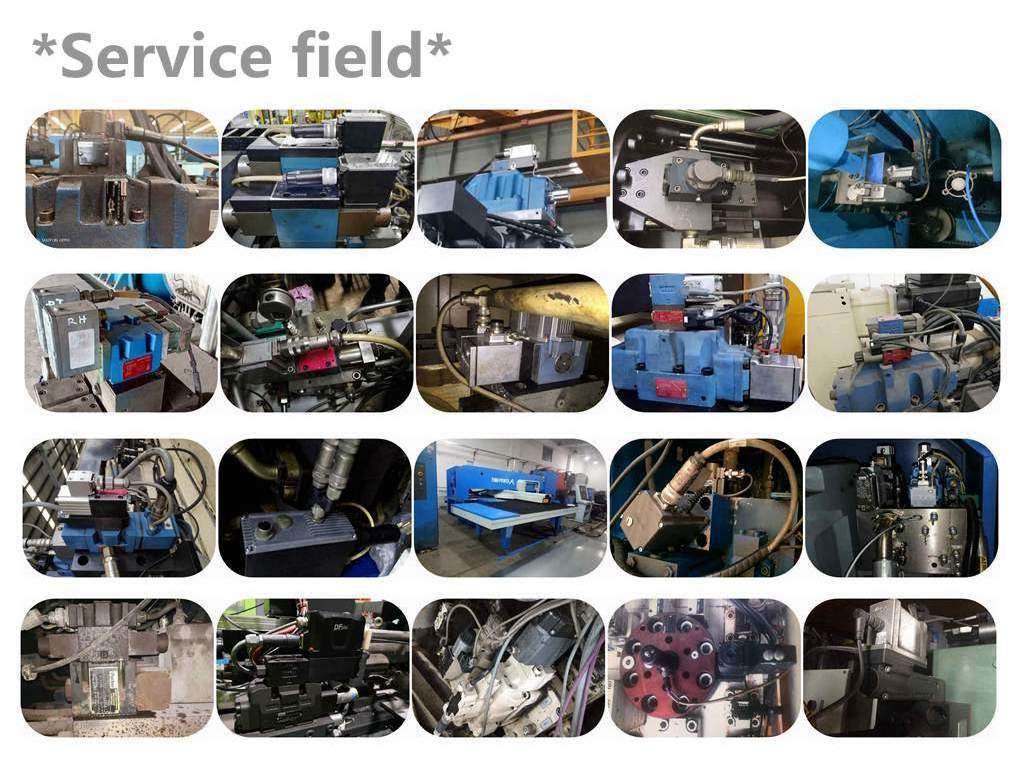

Service providers in the industrial sector

Hot Searches