- Product Details

- {{item.text}}

Quick Details

-

Shipping time:

-

Within 10 days

-

Product Name:

-

Wall panel molding

Quick Details

-

Shaping Mode:

-

Plastic Extrusion Mould

-

Place of Origin:

-

Hubei, China

-

Product Configuration:

-

Die head,Calibrator,watertank

-

Shipping time:

-

Within 10 days

-

Product Name:

-

Wall panel molding

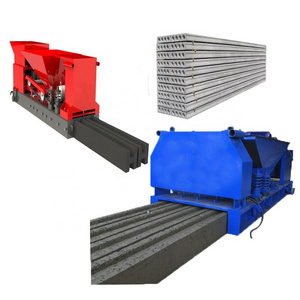

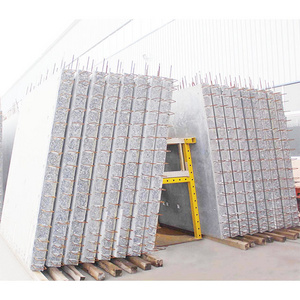

Decorative making machine Precast concrete prefab house compound wall wall panel moulding

Production Introduction:

|

Name |

850mm WPC door plastic mould die makers |

|

Size |

Various Sizes as Per Customer Require |

|

Mould Material |

3Cr17, 3Cr17MoNiV, DIN1.2316 or Negotiable |

|

Mould Cavity |

One or Multi-Cavity |

|

Mould Composition |

Die Head, Aluminum Heating Panels, Calibrators and Water Tank |

|

Feature |

High Polished Surface, Stable Discharging, Soft-hard, Surface Layer, Cladding |

|

Test |

Mould will be tested to get the satisfy sample before delivery |

|

Sample |

Sample will be arranged by express for customer approval |

|

Service |

Provide complete set of formulation, technology and perfect after sale service |

|

Lead time |

30-35days |

|

Package & deliver |

Poly wood case for exporting, each mould will be cleaned before packing. |

|

Remark : If you are interesting in mould and plastic prodcuts, welcome you provide us the details of the product material , size , weight ect, better 2D and 3D drawing. Welcome you to visit us. |

|

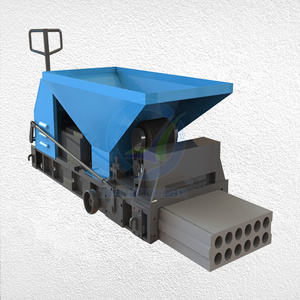

The Composition and Function of each part for WPC Extrusion Mould :

|

Configuration of Mould |

Functions |

Types |

|

Dies head |

Produce continuous,stable,homogeneous profile |

Divided into four standards based on different appearances: D1602,D1802,D2002,D3002 |

|

Calibrators |

Cool down and form the profile, the smaller the resistance is ,the better |

Divided into four standards based on different widths: C1402,C1702,C2002,C3002.The quantity of calibrator parts are decided by profile, and extrusion speed. |

|

Water tank |

Cool down the profile further |

Divided into three kinds: organic glass, stainless steel, pp board. They have wonderful tightness, brief frame, easily be processed. |