- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3800*880*1800 mm

-

Power (kW):

-

9Kw

-

Weight (KG):

-

1200 kg

-

Panel Feed Speed(m/min):

-

18m/min

-

Product Name:

-

Wood Edge Binding Machine

-

Application:

-

Panel Furniture Production

-

Feeding Speed:

-

18m/min

-

Edge Banding Thickness:

-

0.4-5mm

-

Banding Tape Width:

-

10-60mm

-

Mini Width of Wood:

-

≥80mm

-

Working Piece Length:

-

≥120mm

-

Air Pressure:

-

0.7Mpa

-

Size:

-

3800*880*1800 mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Grandio 3D

-

Voltage:

-

Custom Made

-

Dimension(L*W*H):

-

3800*880*1800 mm

-

Power (kW):

-

9Kw

-

Weight (KG):

-

1200 kg

-

Panel Feed Speed(m/min):

-

18m/min

-

Product Name:

-

Wood Edge Binding Machine

-

Application:

-

Panel Furniture Production

-

Feeding Speed:

-

18m/min

-

Edge Banding Thickness:

-

0.4-5mm

-

Banding Tape Width:

-

10-60mm

-

Mini Width of Wood:

-

≥80mm

-

Working Piece Length:

-

≥120mm

-

Air Pressure:

-

0.7Mpa

-

Size:

-

3800*880*1800 mm

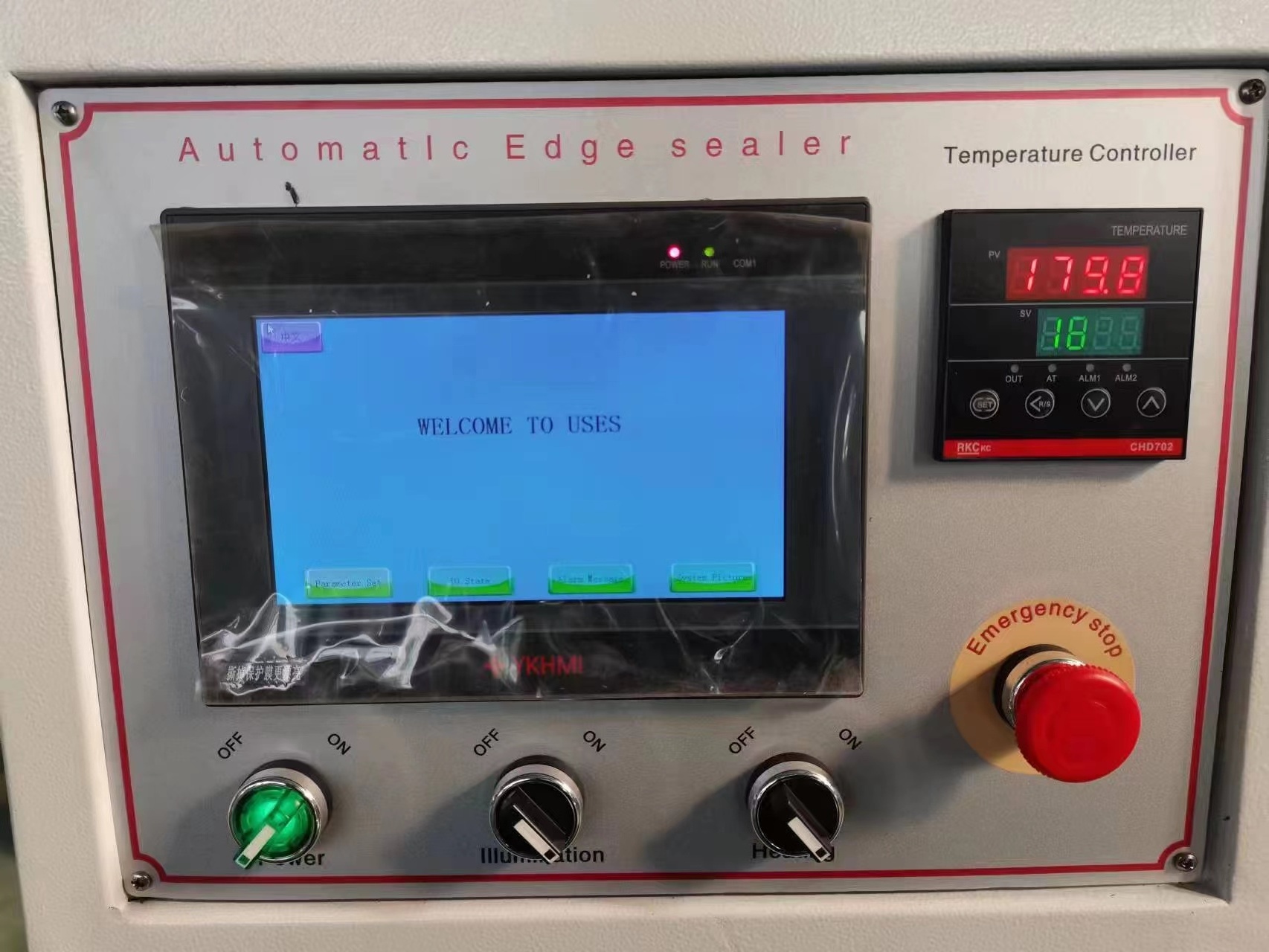

Product Description

Different functions and colors

can be customized according to your requirements.

.

1.End triming and triming unit adopt imported high-motor, it is high precision, lower noise,long life,processing stability.

2.Adopt imported frequency converter,action is sensitive and reliable and with good stability.

3.The function including 6 function:preheating pressing ,gluing,end cutting,rough trimming,fine trimming scraping.

2.Adopt imported frequency converter,action is sensitive and reliable and with good stability.

3.The function including 6 function:preheating pressing ,gluing,end cutting,rough trimming,fine trimming scraping.

4.Machine frame:Welding frame adopts national standard 50 * 90 * 5mm rectangular pipe square tube and bottom 40 * 80 * 5 channel steel welded frame structure, pre-milled table of heavy-duty gantry milling machine to ensure the flatness of the equipment and the whole machine plastic appearance Beautiful and not rusty.

5.The beams are all 18mm thick high-quality high-strength ship plates. Sheet metal shells are 1.8-6mm thick cold plates.

6.There are feed plates and discharge plates on the front and back of the equipment to ensure the smooth operation of the board. It is more convenient to not touch the material..

5.The beams are all 18mm thick high-quality high-strength ship plates. Sheet metal shells are 1.8-6mm thick cold plates.

6.There are feed plates and discharge plates on the front and back of the equipment to ensure the smooth operation of the board. It is more convenient to not touch the material..

|

Model

|

GD-2400

|

|

Panel Feed Speed(m/min)

|

13m/min

|

|

Edge Thickness

|

0.4-3mm

|

|

Edge Width

|

15-55mm

|

|

Edge banding height

|

12-60mm

|

|

Panel thickness

|

8-30mm

|

|

Mini work Panel Width

|

> 80mm

|

|

Mini work Panel Length

|

>120 Mm

|

|

Heating power of plastic box

|

1.5kw

|

|

Plate preheating power

|

0.3KW

|

|

End cutting motor power

|

0.55kw * 2 1200r / min200HZ

|

|

Transmission motor power

|

2.2KW

|

|

Polishing motor power

|

0.2kw*2 1400r / min 300Hz

|

|

Fine trimming motor power

|

0.75kw*2 1800r / min 300Hz

|

|

Total power

|

10kw

|

|

Air pressure

|

0.9MPA

|

|

Machine weight

|

1500KG

|

|

Machine size

|

4200*1000*1800mm

|

Specification

The steel pressing wheel will press the edge band and the plate tightly to make the adhesion more firm, and there is no glue mark on the plate surface..

It is composed of front end trimming and back end trimming. It has a unique protection function of end trimming and plate bumping

the stability... .

the stability... .

The roughing tool is a 15 °allowance for finishing. The automatic tracking by film and high-frequency high-speed motor are used to

realize fast cutting.. .

realize fast cutting.. .

The finishing knife is R2 finishing knife.The automatic tracking by film and high-frequency high-speed motor are used to realize

fast cutting.. .

fast cutting.. .

It is used to eliminate the ripple marks caused by the cutting process of the non-linear motion of the trimming, and make the upper and lower parts of the plate smoother and cleaner..

.

Use cotton polishing wheel to clean the processed plate, remove the redundant glue stains, and make the end face of edge sealing

more smooth and clean by polishing.. .

more smooth and clean by polishing.. .

Double milling cutters are used to re-modify the ripple marks, burrs or non-perpendicular phenomena caused by the cutting board

sawing .. .

sawing .. .

The upper and lower rounding device can make the end face of the plate more smooth and beautiful..

.

Related Products

.

We produce many types of woodworking machines, you can consult me more.

Sample products

The automatic linear edge banding machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc.

The appearance, function and size of all our machines can be customized.

The overall price is affected by the function configuration, the price is for reference only, please contact customer service for the specific price.

Hot Searches