- Product Details

- {{item.text}}

Quick Details

-

Material:

-

wooden case

-

Weight:

-

35KG

-

Size:

-

450*360* 840mm

-

Power:

-

0.46KW, 0.46Kw

-

Productivity:

-

50g/Hour

-

Weight (KG):

-

35 kg

-

Product name:

-

ozone generator

-

Ozone cocentration:

-

30-150mg/L

-

Ozone adjuster:

-

20%-100%

-

Voltage:

-

110V/220V or 380V

-

Ozone tube cooling method:

-

Air cooling

-

After Warranty Service:

-

Video technical support

-

Case:

-

Carbon steel

-

Ozone tube:

-

quartz tube

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

JM

-

Material:

-

wooden case

-

Weight:

-

35KG

-

Size:

-

450*360* 840mm

-

Power:

-

0.46KW, 0.46Kw

-

Productivity:

-

50g/Hour

-

Weight (KG):

-

35 kg

-

Product name:

-

ozone generator

-

Ozone cocentration:

-

30-150mg/L

-

Ozone adjuster:

-

20%-100%

-

Voltage:

-

110V/220V or 380V

-

Ozone tube cooling method:

-

Air cooling

-

After Warranty Service:

-

Video technical support

-

Case:

-

Carbon steel

-

Ozone tube:

-

quartz tube

Product Description

The WQA series ozone machine is a high concentration ozone generation equipment that is water

-cooled

and need to connect with oxygen source

.

Double water cooling

High ozone concentration

Quartz generator tube

Ozone output adjustable

Intelligent alarm

Specification

|

Model number

|

JM-WQA50G

|

JM-WQA60G

|

JM-WQA80G

|

JM-WQA100G

|

JM-WQA200G

|

||||

|

Ozone production (g/h)

|

50

|

60

|

80

|

100

|

200

|

||||

|

power (KW)

|

0.46

|

0.53

|

0.7

|

1

|

1.9

|

||||

|

Ozone concentration(mg/L)

|

30-150

|

30-80

|

30-80

|

30-80

|

30-80

|

||||

|

Operating temperature(℃)

|

≤35

|

≤35

|

≤35

|

≤35

|

≤35

|

||||

|

Air flow(L/min)

|

15

|

20

|

25

|

30

|

65

|

||||

|

Air dew point

|

≤ - 40℃

|

≤ - 40℃

|

≤ - 40℃

|

≤ - 40℃

|

≤ - 40℃

|

||||

|

Oxygen concentration

|

93%±3

|

93%±3

|

93%±3

|

93%±3

|

93%±3

|

||||

|

Cooling mode

|

Water cooling

|

Air cooling

|

Air cooling

|

Air cooling

|

Air cooling

|

||||

|

Power source(V/Hz)

|

220/50

|

220/50

|

220/50

|

220/50

|

220/50

|

||||

|

Installation mode

|

Indoor

|

Indoor

|

Indoor

|

Indoor

|

Indoor

|

||||

|

Ozone power cooling method

|

Water cooling

|

Air cooling

|

Air cooling

|

Air cooling

|

Air cooling

|

||||

|

Overall dimension(mm)

|

450×360× 840

|

450×360× 960

|

450×360× 960

|

680×420× 1040

|

680×420× 1040

|

||||

|

Net weight of equipment(kg)

|

35

|

37

|

39

|

61

|

85

|

||||

Advantages

Compare with other ozone generators

|

High concentration oxygen source ozone generator

|

Other oxygen-rich or air-source ozone generators

|

|

|

|

|||

|

The gas entering the ozone discharge chamber is dried, water removed and dust filtered And

cooling and other pre-treatment process

(the machine is equipped with an

efficient cold and dry machine

), to ensure The gas quality is stable and ozone production decays very slowly.

|

Simplified Single drying cylinder affected by external temperature, humidity, pollution, ozone attenuation High speed and unstable ozone production, easy to cause breakdown and other phenomena

|

|

|

|

|||

|

The power system

adopts IGBT circuit

with complete protection function. Use frequency conversion Technology, to achieve automatic frequency tracking, waveform stability.

|

Unable to achieve frequency tracking, does not work at its best.

|

|

|

|

|||

|

A

high concentration (93%) oxygen unit

is used for air entering the ozone generator Gas treatment, ozone content is not limited by environmental conditions, high concentration.

|

Oxygen rich source uses low concentration (about 30%) oxygen supply, easy to fail, Low ozone concentration

|

|

|

|

|||

|

No need to install in the air duct or chassis

, suitable for explosion-proof environment.

|

Some devices need to be installed in the air duct or chassis, and are not suitable for flammable and explosive rings Border.

|

|

|

|

|||

|

The use of

advanced air cooling technology

to ensure that the ambient temperature of ozone generation is relatively constant, and the ozone production is not affected by the ambient temperature

|

The air-cooled ozone generator is greatly affected by the ambient temperature and has the heat dissipation effect The O3 output is

unstable. |

|

|

|

|||

|

Double anti-backwater system

is used to completely eliminate backwater phenomenon. (optional)

|

No backwater protection or simple check valve

|

|

|

|

|||

1, Long service life of the equipment:

the selected configuration and materials are well-known at home and abroad, and the quality is the best, especially the core part of the ozone equipment - ozone discharge material is made of 316L stainless steel. This material is the highest grade of stainless steel because it is very resistant to corrosion. As we all know, when the high voltage discharge in the discharge chamber produces ozone, the high voltage corrodes the discharge material very much, and the ozone generated is more corrosive, which requires the corrosion resistance of the discharge material to be strong, and the discharge material 316L stainless steel used by our company is the material used in aviation, its biggest function is strong corrosion resistance, so as to ensure the long service life of the ozone equipment. This series is basically maintenance-free.

2, The equipment is stable:

the use of frequency conversion power supply, because the required frequency is not the same when the high voltage discharge produces ozone, so the frequency is required to be automatically adjusted. The frequency conversion power supply currently used by our company can achieve automatic frequency tracking so that the equipment can output ozone stably. Coupled with the use of water cooling technology, why is it important for temperature cooling, the reason is that ozone gas is a very active gas, if the temperature rises to a certain range, ozone will soon be reduced to oxygen, can not achieve the ideal disinfection effect. But my company uses water cooling technology to control the temperature within the range required for ozone, so that

Maximum duration of stable sterilization.

3, Ozone production is large, high concentration:

the principle of ozone production is high voltage discharge, ionizing oxygen atoms in the air to produce ozone, so the air source is required to be better, that is, the raw materials to produce ozone. This series of products use oxygen as the air source, through the oil-free air compressor into, plus cooling, drying, oil-water filtration, dust filtration, freeze-drying and a series of processing, so as to ensure the high cleanliness of the air source, and then add a high concentration oxygen system, sample to ensure the feed

The amount of oxygen into the ozone discharge chamber is large and the purity is high, which can ensure the ozone production is large and the ozone concentration is high.

4, Quality after-sales service

: most of our R & D personnel in the professional field more than 20 years, the core R & D personnel in the ozone industry experience more than 26 years. Ozone core components are independently developed, with independent patented technology, and specially customized, quality and safety are effectively controlled. Our work team and sales team can guarantee fast and efficient after-sales service for our products worldwide. We have a complete supply system to ensure the demand for product accessories. Therefore, if you have any questions, please feel free to contact us at your convenience.

① Non-human factor ozone generator machine quality problems one year warranty.

② Non-human factors ozone generation components (discharge tube) lifetime maintenance.

③ Free repair or replacement of parts damaged due to quality problems of our products except human factors.

④ In the warranty period, if the fault occurs due to the manufacturing quality problems of the product, we will be responsible for repairing or replacing the damaged components and accessories free of charge.

⑤ If you need on-site service or guide our after-sales service personnel to ensure that they arrive at your designated place within 7 working days.

5, Quality assurance:

1. The shell material of the chassis is SUS304 stainless steel or cold plate spray, and the electronic components are provided by domestic and foreign famous brand manufacturers.

2. Each production process strictly implements the ISO9001 quality certification system to ensure that the whole machine meets the enterprise standards and industry verification standards.

3. If the customer thinks it is possible and necessary, the company will invite relevant personnel of the customer to the site to participate in product factory inspection and factory acceptance.

4. Guarantee to provide spare parts required by customers within the product warranty period and life period.

5. Urgent users, want users to think, to meet customer needs. Supports OEM and ODM.

INTELLIGENT CONTROL HIGH EFFICIENCY AND ENERGY SAVING

One year warranty of the whole machine!

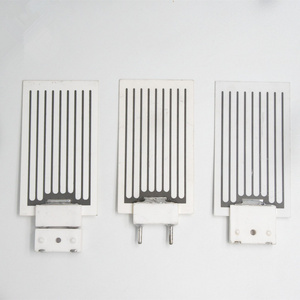

Ozone generating tube

1. The core component of ozone generation is quartz manufactured using German technology

The occurrence tube has a much better resistance to electrical shock than ceramic media, and its resistance to

Strong mechanical impact ability and maintenance free.

2. Large ozone production and high ozone concentration allow for maximum utilization

The functions of the power system and cooling system are to produce large quantities of high concentration odors

The key technology of an oxygen generator, suitable for frequencies between 400-3000Hz, electrical

Voltage 3.7-4.5KV, dielectric constant ε= 6.19, high breakdown strength

At 9 KV;

3. The generator tube is designed as an independent unit for discharge, making it easy to replace and not mutually exclusive

Impact;

4. Enhanced surge voltage resistance of discharge electrodes, improving equipment reliability

Ozone power supply

The CH-800A intelligent ozone power supply is a 32-bit ARM7 core

A new type of intelligent ozone generator power supply with a computing core, which has a built-in closed circuit

The circuit of the loop detection control system enables it to adapt to different powers and types

Class of ozone generator devices, in terms of driving capacity stability and ozone generation

There has been a significant improvement in productivity.

The CH-800A intelligent ozone power supply can be adjusted based on the ozone generator device

Automatic frequency control for different working current states during actual work processes

Fine tune the rate to achieve the best working condition that matches the ozone generator tube

state

Automatic protection system

The machine comes standard with one control board and one protection board each, for the generator tube, power supply

Real time multi-point monitoring of loads such as oxygen production units, air compressors, and refrigerated dryers

Measurement. Overcurrent, module overcurrent, module overtemperature, cooling water interruption, cooling

Insufficient water flow and accumulated water in the discharge chamber of the generator may endanger the generator

The faults of the system can be given warnings based on the characteristics of the faults

Delayed shutdown, immediate shutdown for disposal, while emitting sound and light alarms

Alarm signals, reporting the cause of faults, greatly improving the safety of the system

And reliability.

Electronic control system:

The main electrical controller components of the machine are all imported first tier brands (Schneider)

German, Omron, ABB) and equipped with remote control and local control cutting

Changing functions significantly improves device stability and operational convenience.

Intelligent control:

Water inlet, drainage, oxygen regeneration, oxygen blowing, automatic cooling water level

Control, precise timing, reliable actions, and eliminate the burden of manual operation.

Applications

Packing & Delivery

Packaging:

We insist on making the best package. This package is solid which contacts foam inside. We have professional in packing and avoid any troubles during shipping.

Delivery:

1) 2~8 days for portable ozone generator order.

2) 10~30 days for industrial/middle size ozone generator order.

3) Shipping could be courier, airline or sea.

Hot Searches