(1) USB, RS232 communication port

(2) F1-F8 function selection buttons

(3) Quick menu key

(4) Auxiliary Panel

(5) Speed ratio selection

(6) Auxiliary Panel②

(7) Program lock

(8) Power on switch

(9) JOG feedrate switch (slow, fast)

(10) Other operation aera

(11) Power off switch

(12) Cycle start and stop buttons

(13) Emergency-stop switch

- Product Details

- {{item.text}}

Quick Details

-

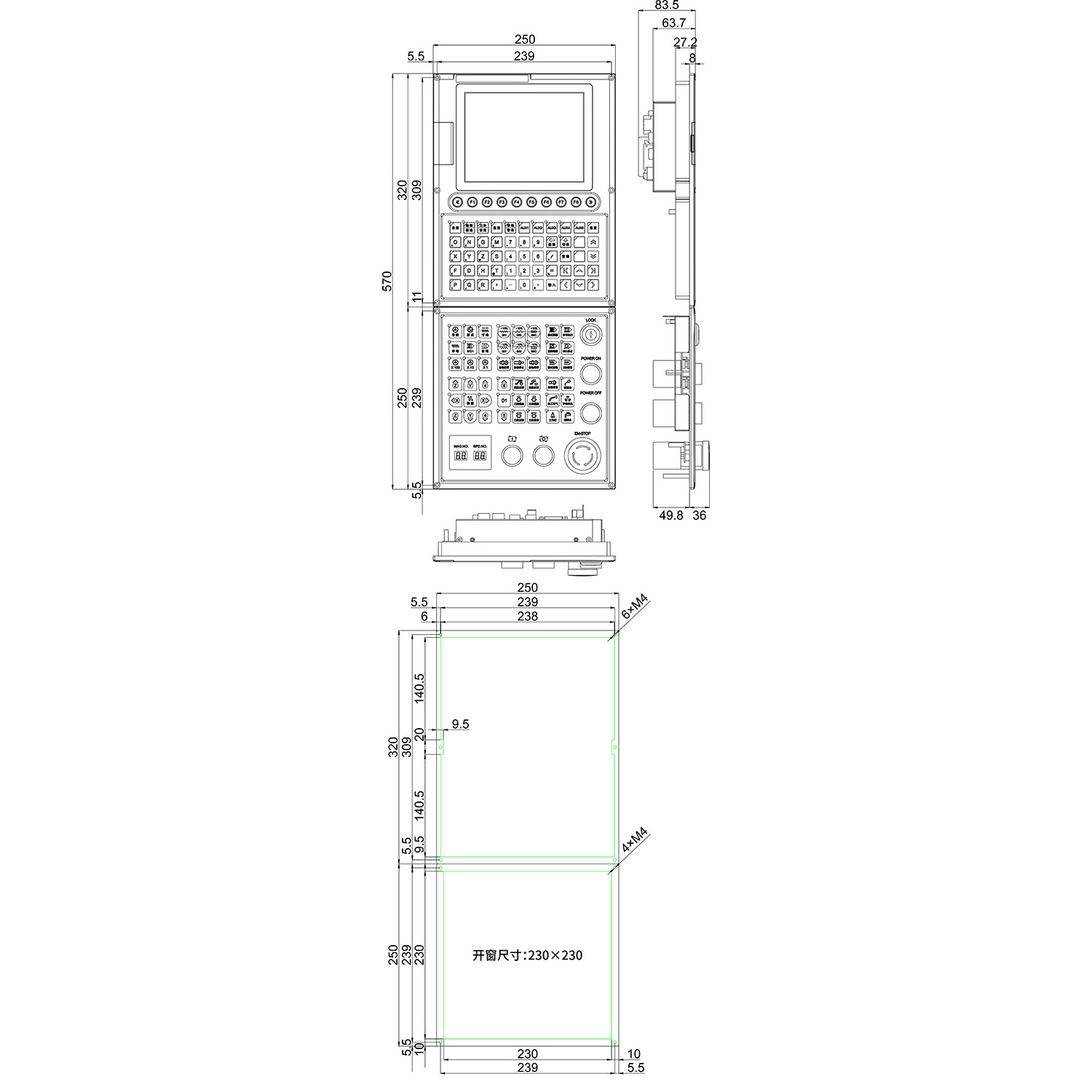

Dimension(L*W*H):

-

41*36*37CM

-

Weight(KG):

-

5.5

-

Product Name:

-

8 Inch Milling Machine CNC Controller System

-

Display:

-

8 Inch LCD

-

RAM:

-

2GB

-

Program Capacity:

-

4GB

-

Operating System:

-

RT Linux

-

Transmission:

-

USB/RS232/RS485/LAN/WIFI

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Marketing Type:

-

New Product

-

Brand Name:

-

FINGER CNC

-

Dimension(L*W*H):

-

41*36*37CM

-

Weight(KG):

-

5.5

-

Product Name:

-

8 Inch Milling Machine CNC Controller System

-

Display:

-

8 Inch LCD

-

RAM:

-

2GB

-

Program Capacity:

-

4GB

-

Operating System:

-

RT Linux

-

Transmission:

-

USB/RS232/RS485/LAN/WIFI

Feature And Function Introduction

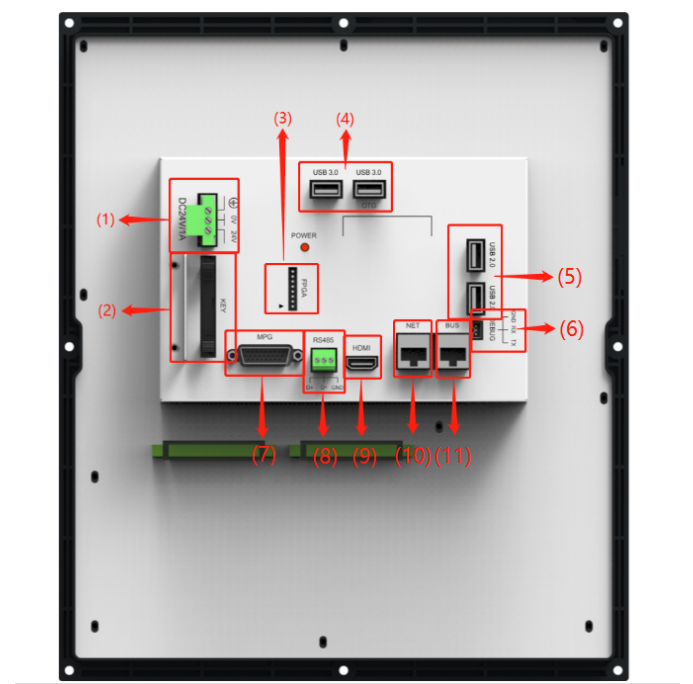

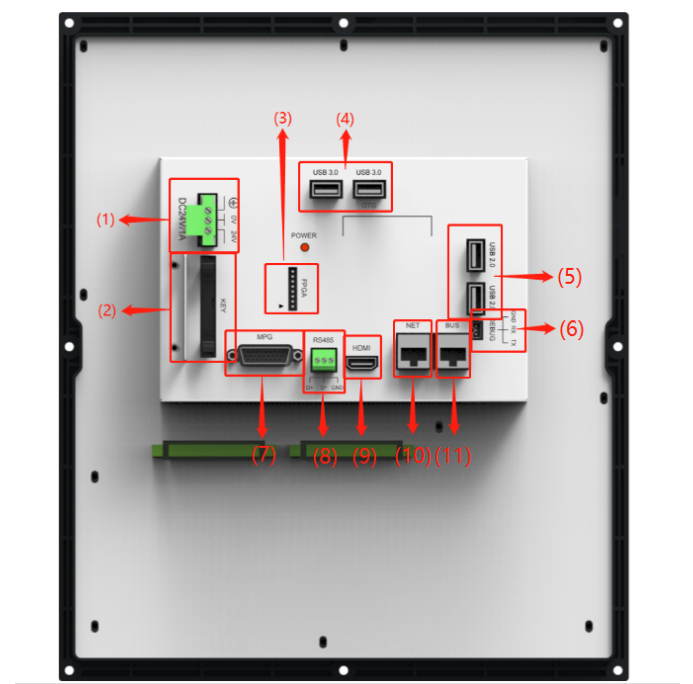

Interface Introduction For Back

(1) DC 24V power supply port

(2) System keypad port

(3) Firmware updating port

(4) USB 3.0 port

(5) USB 2.0 port

(6) Debug port

(7) MPG port

(8) RS485 communication port

(9) HDMI interface for external displayer connection

(10) Local aera network supports OPC-UA,Modbus TCP,Ftp,etc..

(11) Field Bus interface supports EtherCAT/MⅢ

|

System Specifications

|

|

|

|

Product Name

|

High Speed Precision 8 Inch Open Cnc Control Or Milling Machine With Multiple Tool Magazine Options Cnc Controller System

|

|

|

Installation Method

|

Vertical

|

|

|

Number of Standard Channels

(Maximum Supported Channels,option)

|

1(1)

|

|

|

Number of Standard Axis

(Maximum Number of Axes,option)

|

4(5)

|

|

|

Maximum Number of Spindles

|

1 spindle

|

|

|

Porgam Pre-fetcth Speed

|

1000b/s

|

|

|

Control Accuracy

|

0.00001mm

|

|

|

Tool Compensation Groups

|

160 Groups

|

|

|

Transmission Interface

|

USB/RS485/LAN/WIFI

|

|

|

Product Positioning

|

3 axes standard milling machine

|

|

|

Commonly Used Models

|

XYZ+C

|

|

|

Standard Accessories

|

Standard 5m cable, standard 24-input/16-output IO board

|

|

|

Max. Expansion I/O

|

Maximum expansion to 64 IO points

|

|

Customized UI

Customized UI

Provide basic source code and highly customizable UI layout, color, style and operation, allowing you to create a more user-friendly and personalized tool.

Original User Interface

Customized User Interface

The soft keyboard can be freely configured to better suit your operating habits.

Pre-customization of soft keyboard

Post-customization of soft keyboard

Provide a wide range of components for deep configuration, including IoT, graphics, waveform monitoring, CAM, tables, and more. Our industry-leading UI customization solution allows for more efficient operation and enhances industrial digitization

.

Customized Macro_C

1. The IDE editing environment supports online/offline debugging, graphical simulation, Chinese naming, and rich function interfaces.

2. The file management structure is clear.

3. Bringing great convenience to customized programming.

Customized PLC

1. PLC compliant with IEC-61131 standards and specifications.

2. Providing basic source code and supporting editing modes such as LD/FBD/ST/C language.

3. The software includes encryption, performance analysis, PLC tracking, and rich function blocks, simplifying your path to customization with modular programming and giving you

control over key processes.

Basic Source Code, Modular Editing.

Permission Management

Key Data Encryption

PLC Tracing

Performance Analysis

Q: Why should you buy from us not from other suppliers?

A:FINGER CNC Technology We provide high performance and complete development platforms and tools, including PLC, HMI, MACRO,CAD/CAM, etc. We are the advocate of open CNC technology and have long been committed to the research and development of open CNC systems. We provide our customers with a cost-effective and convenient way to develop customized automation technologies. In addition, we offer high-speed and high-precision motion control technology, high-caliber controllers, multi-axis and multi-channel controllers, IEC 61131-compliant automation technology, and reliable and stable EtherCAT devices.

Q:What is your main products?

A:FINGER Technology have accumulated rich product experience and customer base in high-end turning and milling centers, grinding machines, spring machines, tooling machines, woodworking machines, wire winding machines, spinning machines, tube bending machines, 3C electronics and other industries.

Q:What's the warranty on your parts?

A:We have the professional engineer to prefect testing equipments and make sure they are 100% working before they are dispatched. System can be upgrade by USB. Lifetime Software upgrade service.

Q:When the machine can’t work well,What should I do?

A.(1)Salesman is online for 24-hours, they can check the problems with engineer and then give you solutions as soon as possible.

(2)Our machine is with one’s year warranty, If any problems of machine parts under “normal use”,new machine parts will be sent by air in free.

(3)Please rest assured that operation CD and manual will be offered along with machine,making you can operate the machine easily.

Q: How long is your delivery time?

A:Generally it is 14-30 days if the goods are in stock. or it is 7-14 days if the goods are not in stock, it isaccording to quantity.30 days if customized manufacturing.

Hot Searches