- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Apartment

-

Design Style:

-

Modern

-

Type:

-

calcium silicate boards

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SSJD

-

Model Number:

-

Calcium Silicate Insulation Board

-

Product:

-

Calcium Silicate Insulation Board

-

Function:

-

Thermal insulation, fire proof

-

Raw Materials:

-

Quartz sand

-

Density:

-

170-500 kg/m³

-

Category:

-

Calcium Silicate

-

Certificate:

-

CE&ISO&TUV

-

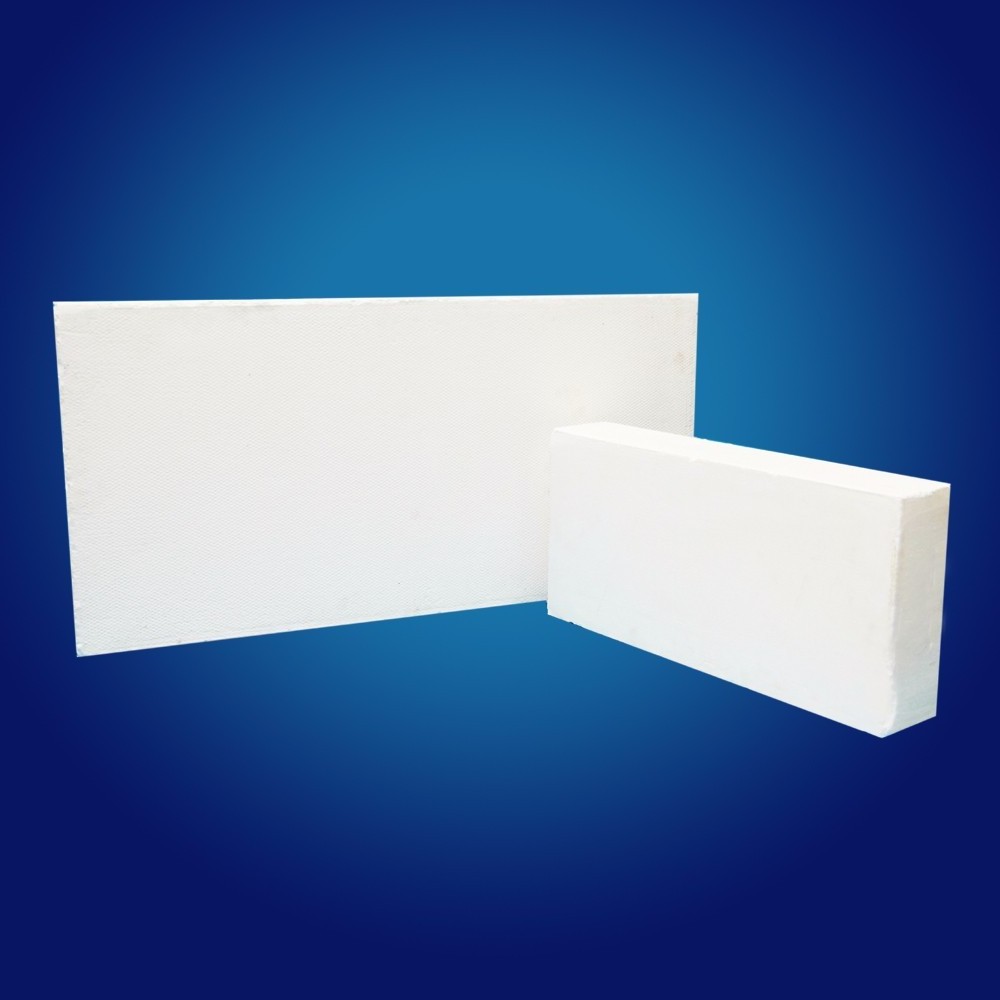

Thickness:

-

25-100mm and 10mm(High Density)

-

Color:

-

White

-

Advantage:

-

Heat resistance/No asbestos

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Apartment

-

Design Style:

-

Modern

-

Type:

-

calcium silicate boards

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SSJD

-

Model Number:

-

Calcium Silicate Insulation Board

-

Product:

-

Calcium Silicate Insulation Board

-

Function:

-

Thermal insulation, fire proof

-

Raw Materials:

-

Quartz sand

-

Density:

-

170-500 kg/m³

-

Category:

-

Calcium Silicate

-

Certificate:

-

CE&ISO&TUV

-

Thickness:

-

25-100mm and 10mm(High Density)

-

Color:

-

White

-

Advantage:

-

Heat resistance/No asbestos

Calcium Silicate Boards Introduction:

Density:

170-500 kg/m³

Raw materials: Quartz sand

Thickness:

25-100mm and 10mm(High Density)

Asbestos: 100% Non Asbestos

Function: Thermal insulation, fire proof

Calcium Silicate Insulation Board is a kind of board dominated by silicic and calcic materials and made by such manufacturing process as pulping, shaping, steam curing, drying and post processing etc.Its highest working temperature is 1000/1050/1100 ºC, can be widely used in metallurgy, petroleum, chemical, mechanical, electrical, light industry and other industrial kiln.

The products sold well all over the world and exported to Japan, South Korea, Thailand, Indonesia, Malaysia, Pakistan, Vietnam, Hong Kong, Singapore and other countries and regions. Using the materials can reduce equipment heat loss, narrow the kiln size, and improve working conditions.

Calcium Silicate Boards Technical Data:

|

Items \ Product |

Calcium silicate board |

|

Classified Tem ( ℃ ) |

1000 ℃ /1832 ℉ |

|

Density (kg/m³) |

200-500 |

|

Bending Strength (Mpa) |

≥0.5 |

|

Conpressive Strength (Mpa) |

≥0.9 |

|

Thermal Conductivity ( w/m.k ) |

≤ 0.056 |

|

Linear Shrinkage ( % ) |

≤1.5 |

|

Max. working Tem. ( ℃ ) |

1000/1050/1100 |

|

Size (mm) |

1000*500/600*300 |

Calcium Silicate Boards Application:

Used in electric power, heat and other roads, chemical, metallurgical and other industries equipment, heat pipe, boiler body, kiln and so on. In recent years, widely used in thermal power plant heating pipe straight steel casing steel, plastic sets of steel, with glass fiber reinforced concrete composite insulation pipe, and can be processed into special-shaped products.

Calcium Silicate Boards Features:

1. High strength: in the condition of similar bulk density, it is the highest strength insulation material in inorganic hard insulation material

2. Heat resistance: no deformation in working temperature

3. Thermal insulation: lower thermal conductivity than other hard block insulation material

4. No asbestos: avoid various diseases caused by the asbestos fiber and other harmful substances

Notice: Safety first. Follow good safety/industrial hygiene practices during insulation. Wear appropriate personal protective equipment. Read SDS and literature before specification and insulation.