- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

HX

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

6050*1500*1600

-

Weight:

-

4 kg

-

Feeding width:

-

110mm

-

Marketing Type:

-

New Product 2021

-

Product name:

-

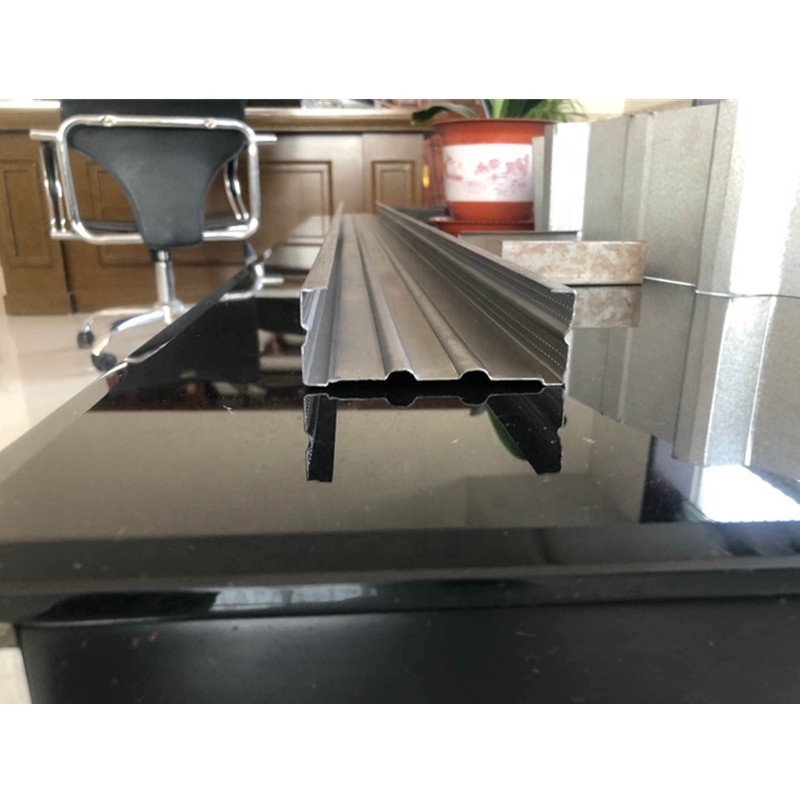

stud light steel frame making machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

Cr12

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Color:

-

Customised

-

Material thickness:

-

0.3mm-0.8mm

-

Cutting type:

-

Hydraulic Guide Pillar Cutting

-

Main frame:

-

350H Steel

-

Main Motor Power:

-

4kw

-

Motor brand:

-

Lichao

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10 m/min-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

HX

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

6050*1500*1600

-

Weight:

-

4 kg

-

Feeding width:

-

110mm

-

Marketing Type:

-

New Product 2021

-

Product name:

-

stud light steel frame making machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

Cr12

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Color:

-

Customised

-

Material thickness:

-

0.3mm-0.8mm

-

Cutting type:

-

Hydraulic Guide Pillar Cutting

-

Main frame:

-

350H Steel

-

Main Motor Power:

-

4kw

-

Motor brand:

-

Lichao

Factory Lifetime Service!

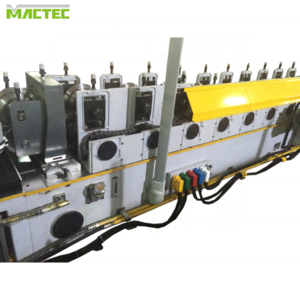

China rollformer manufacturer direct factory high quality

c z u keel machine

Price with ISO9001/Ce/SGS

WHY CHOOSE US?

We care about USER EXPERIENCE

Controller is the "CPU" of forming machine. We choose Siemens PLC from Japan.

With touch screen mode, let your workers free their hands!

We care about YOUR CONCERN

1. Capacity: 12-15 sets/month

2. Delivery: in only 5-8 weeks for urgent order

We care about QUALITY

1. ISO, CE certificate

2. Take the EUROPEAN Quality Standard

3.Choose the Best Material and Components

|

NO.

|

Name

|

Specification

|

|

1

|

Suitable to process

|

(Prepainted)galvanized steel strips

|

|

2

|

Rollers

|

12Rows

|

|

3

|

Main frame

|

Square steel frame

|

|

4

|

Dimensions

|

5.5*0.6*1.5m

|

|

5

|

Wallboard size

|

Memorial arch

|

|

6

|

Weight

|

About 3.2T

|

|

8

|

Motor power

|

5.5Kw

|

|

9

|

Pump Station Motor

|

3Kw

|

|

10

|

Thickness of the plate

|

0.4mm - 0.8mm

|

|

11

|

Productivity

|

20m/min to 25m/min

|

|

12

|

Cutting way

|

Hydraulic tracking cutting

|

|

13

|

Diameter of the roller

|

Φ50mm

|

|

14

|

Voltage

|

380V 50Hz 3phases

|

|

15

|

Control system

|

PLC control

|

|

16

|

Touch screen

|

Delta

|

|

17

|

Rolling materials

|

45# forging steel with chromium plate

|

|

18

|

Length Tolerance

|

±2mm

|

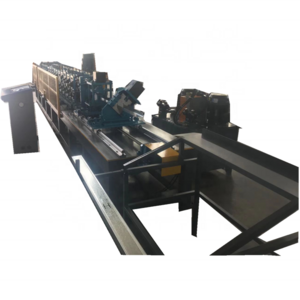

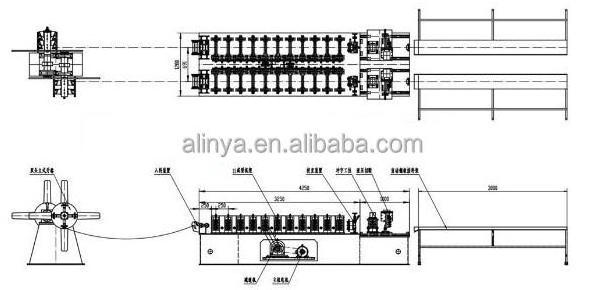

Working flow:

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Auto cutting→Products receiving

Why choose this machine?

:) Fully Automatic Control System with PLC.

:) Easy operation: Key in the length and quantity on the control panel.

:) Two years warranty for free, and beyond two years if any part broken, tell us and pay us we delievery any part u need. And support technical skills for machine for whole life.

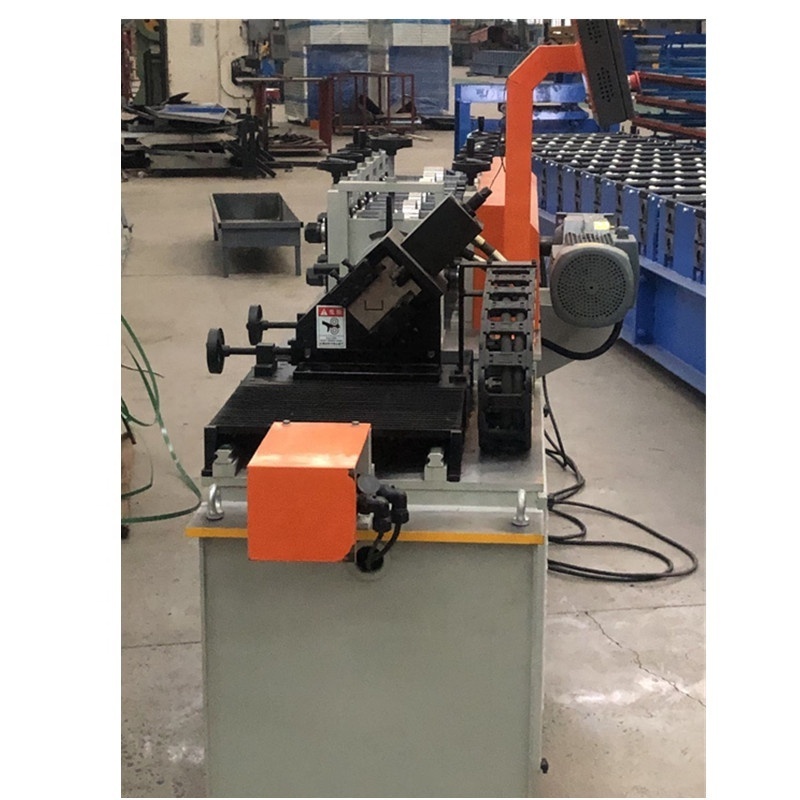

Machine Parts

Name: Main Roll Forming Machine

Brand: HX

Material of rollers:

High grade 45# Forging Steel

,

roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Machine Parts

Name: Shearing Mechanism

Brand: HX

It adopts the Motor drive and automatic location to decide the dimension and cut the target products.

Cutting way:

Hydraulic cutting

Machine Parts

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

2 pieces 3meters

Can not find the machine you need?

Why not customize it!

You can rely on our team!

We have engineers with experience more than 18 years in metal forming industry.

Full praise from customers:

About us!

Tianjin Haixing is a professional cold roll forming machine manufacturer, We have been focusing on this field for 22 years.

Our equipment includes

light keel roll forming machine

.

Haixing has employed a team of engineers for more than 20 years. At the same time, our machines use branded electrical components, raw materials from branded steel factories, strict process control, two-year warranty, installation and training services.

We have provided services to customers in 85 countries/regions and provide solutions based on your local hot-selling models,

such as 65 countries in Germany, the United States, Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, Japan, South Africa, Kenya and other different regions. We have extensive experience in the needs of different countries, such as profile, thickness range, use, installation, etc.

You can rely on our team!

Packing and delivery

1). Tighten to container with steel wire rope and welded machine with container by iron

2). Main forming machine and un-coiler is naked(If you need we can also packed with water-proof plastic)

3). PLC control system and motor pump are packed in box with water proof paper coverage

FAQ

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design,processing, assembling to quality control, we refuse to cut corners.

Q: How long does it take to manufacture the machine?

A: Ingeneral, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control,including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

Get Free:

”Send”

below get profile drawing & design technical support by our 18 year experience technicians FOR FREE!

Hot Searches